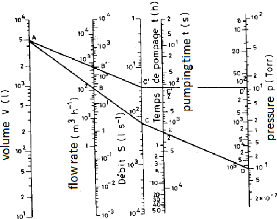

3.1.4. Duration of evacuation process

The evacuation process of a vacuum system is generally

non-stationary. During evacuation, the pressure and flow of each point of the

installation vary. The evacuation duration is the time it takes to obtain a

certain pressure in the vacuum installation.

For a piping with high conductance, we'll have:

V

??= ?? ????(??0 ?? ) (3.15)

V : The chamber volume (m3);

36

Chapter 3: Vapor deposition and thin layer

characterization techniques

P0 : The pressure of the gas at the initial instant

(N/??2);

P : The pressure of the evacuated gas

(N/??2).

In the general case, the pumping time can be obtained using

the nomogram shown in figure 3.4. To use it, first calculate the quotient V/??

by joining the points corresponding to V and Q on the respective straight

lines. The obtained point on the line V/?? is joined to the point of the line P

which corresponds to the pressure P which we wish to obtain. The point of

intersection on the line t gives the necessary pumping time.

??/??

Fig.3.4 Nomogram for calculating the pumping time

3.2. The theory of plasmas

In their normal state, gases are electrical insulators. This

is due to the fact that they don't contain free charged particles, but only

neutral molecules. However, if they are given fairly strong electric fields,

they become conductors. The phenomena that occur are called discharges in gases

and are due to the appearance of electrons and free ions. The result of a

discharge in a gas is the production of an ionized gas.

The degree of ionization of a gas is defined by the ratio

á:

n

?? = (3.16)

n0 + n

n0 : The number of neutral particles per unit of volume;

n : The number of ionized particles per unit of volume.

The degree of ionization value varies from very low values (of

the order 10-10) to one. When the degree of ionization is equal to

unity, it is said that the gas is totally ionized or that it constitutes

plasma.

37

Chapter 3: Vapor deposition and thin layer

characterization techniques

The set of concepts, methods and results of the study of this

state of matter constitutes the physics of plasmas. In our environment, the

plasma phase is totally absent in the natural state, whereas on the cosmic

scale, more than 99.9% of the visible matter occurs in this phase.

When heating a gas at a sufficiently high temperature (of the

order of 104 K), the mean translated energy of its

molecules can become of the same order as their ionization energy. Under these

conditions, when two molecules collide, one of them can be ionized.

The probability of ionization as a function of energy is

characterized by a threshold. This is the ionization energy. The ionization

energies for all species are found in data banks.

Among all the weakly ionized gases we distinguish three

families:

- Lowly ionized gases: in which some ions and electrons move

in the middle of a sea of neutral molecules. Ions and electrons interact only

with neutral molecules;

- Highly ionized gases without interactions between particles:

in this plasma the charged particles follow without any collision a trajectory

determined by external electromagnetic fields; - Highly ionized gases with

interactions between particles.

Coating with plasma involves of modifying the state the

surface by one of the three following methods:

- The deposition on the surface a thin layer of a few

material;

- Chemical reaction with the surface itself (oxidation,

nitriding) or physicochemical transformation thereof (modification of adhesion,

surface energy);

- Erosion of the surface either by chemical action (formation

of pores between one or more atoms of the surface) or ion sputtering due to

plasma ion bombardment of the surface atoms or chemically-assisted sputtering,

which combines ion bombardment and chemical erosion.

The main types of plasma are: hot plasma and cold plasma.

The plasma is called «hot» when the temperature of

the ions and electrons is high (greater than 107 k ). In

this case, the medium is completely ionized.

The plasma is called «cold» when the electrons are

hot (on the order of 104 k), and the ions are cold (from

300 to 104 k). The medium in this case is weakly ionized

(ionization rate is close to 10-6 until 10-2

per neutral species).

3.3. Coating in the vapor phase (PVD, CVD)

Vapor deposition techniques allow us to have a deposit of thin

layers (generally less than 10ìm) with very interesting physical and

mechanical characteristics. Generally we distinguish two methods of deposition

from the vapor phase: physical vapor deposition (PVD) and chemical vapor

deposition (CVD).

In PVD processes, evaporation, sublimation or sputtering by

ionic bombardment are used to transform the material of deposition in the vapor

phase. These vapors are then condensed on the surfaces. The process can be

summarized by the formula:

???????? s??l??d ??????s

??????s ??????ld s??l??d

38

Chapter 3: Vapor deposition and thin layer

characterization techniques

The absence of a chemical reaction gave the designation:

physical deposition.

In CVD, one or more vapors (two in general) are used,

which react with each other on a surface to form a defined compound and

volatile products of the reaction:

AG + BGas + hot surface Csolide + DGas

+ "'

The various processes of the PVD and CVD techniques are

given in Table 3.2

|

Chemical vapor deposition(CVD)

|

Physical vapor deposition (PVD)

|

|

- Conventional chemical vapor deposition (CVD) -

Metalorganic chemical vapor deposition (MOCVD)

- Plasma-enhanced chemical vapor deposition

(PECVD)

|

- physical vapor deposition by evaporation: - PVD by

direct evaporation

- PVD by Ionic deposition

- physical vapor deposition by sputtering

|

Table 3.2 Various processes of the PVD and CVD

3.3.1. Chemical vapor deposition (CVD) techniques

3.3.1.1. Conventional chemical vapor deposition (CVD)

Two processes can be distinguished according to the

gaseous environment:

- Static processes:

It is an isothermal process, in which the bar to be

coated is placed in a closed chamber in contact with a mixture of a donor

eventually alloyed (metal powder containing the element to be deposited), an

activator (halogen compound) and an inert diluent which avoids self-sintering

of the assembly. At 400 ° C, the activator reacts with the donor element

to form the metal vapor. The subsequent heating at temperature between 800

° C and 1100 ° C under a hydrogen atmosphere allows ensuring the

production of the coating in a homogeneous manner.

- Dynamic processes:

For this process, the environment of the bar to be

coated is continuously renewed by the circulation of a gaseous mixture of the

material of the deposition formed outside the reaction chamber and carried by

forced convection on the surface of the bar.

The need for high temperature in conventional chemical

deposits to initiate the different chemical reactions leading to the metal

transfer, several paths has been followed to do so, and two are the most

developed for industry: the use of organic gaseous species (OMCVD) and the

assistance of plasma (PACVD).

3.3.1.2. Metalorganic chemical vapor deposition

(MOCVD)

The idea is to reduce the temperature of the

conventional CVD by substituting the halogenated compounds which have a higher

decomposition temperature than the new organometallic compounds.

The advantage of such a process is the lowering of the

processing temperature compared with conventional CVD processes, taking the

example of chromium deposition, the temperature is

39

Chapter 3: Vapor deposition and thin layer

characterization techniques

reduced from 1000 °C for the conventional CVD to 500

°C using by bis-benzene chrome Cr(C6H6)2, the rupture of the radical

bonding results in the formation of chromium carbide.

On the other hand, the disadvantages of this process are: the

high cost, the toxicity for a large number of them and the lack of stability

over time.

Electronics is the most favorable field for the development of

the OMCVD technique, with layers of some ten of nanometers.

3.3.1.3. Plasma-enhanced chemical vapor deposition

(PACVD)

A second way to reduce the temperature of the deposit to avoid

any further heat treatment (see table 3.3), is to use the assistance of plasma

and the use of chemically activated species such as ions and free radicals.

These species are produced in the gaseous phase by electron-molecule

collisions; the assistance of a plasma allows to obtain deposition speed

varying from 1 to a few tens of ìm/h in a temperature range comprised

between 150 and 500 ° C.

|

Deposition temperature (°C)

|

|

materiel

|

CVD

|

PACVD

|

|

Tungsten carbonate

|

1000

|

325-525

|

|

Poly silicon

|

650

|

200-400

|

|

Silicon nitride

|

900

|

300

|

|

Silicon dioxide

|

800-1100

|

300

|

|

Titanium Carbide

|

900-1100

|

500

|

|

Nitride of titanium

|

900-1100

|

500

|

Table 3.3 Typical temperature of deposition for CVD and

PECVD

3.3.2. Physical vapor deposition Processes

(PVD)

The PVD technique consists of the formation of a coating under

reduced pressure in three distinct stages: vaporization of the species to be

deposited, transport of these species and finally the condensation and the

growth of the deposit. There are two main processes of this technique, those

using evaporation and those using sputtering.

3.3.2.1. Physical vapor deposition by direct

evaporation

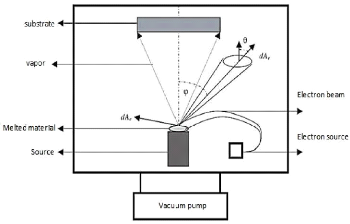

Evaporated species (atoms, molecules) propagate in a straight

line and condense on the cold zone (see figure 3.5). The transfer of the

species takes place in molecular flow under a pressure of less than

10-2 mbar, the rate of evaporation of the atoms can be found by the

hertz-knudsen equation:

??(??) = av ??

2??R?? (P??- P) (3.17)

a: Stricking coefficient, it is the probability of

having an adsorption; P: Gas pressure;

P??: Saturated vapor pressure;

R: Ideal gas constant.

40

Chapter 3: Vapor deposition and thin layer

characterization techniques

The advantages of this process are:

- High deposition rates (more than 200 ìm / h);

- Low processing temperature allowing deposits on plastic.

The disadvantage of this process is that the deposits have a

weak adherence and are often powdery, because they are made in a vapor phase

with a low energy. It is often necessary to heat the substrate towards 300 to

400 °C, or to use subsequent heat treatments to improve the adhesion.

Fig.3.5 Schematic representation of physical vapor deposition

by evaporation 3.3.2.2 Physical vapor deposition by ionic

deposition

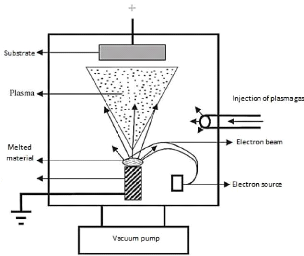

The ionic deposition differs from the direct evaporation by

the phase of transfer and condensation of the vapor. In this case the vapor

must pass through plasma to arrive into a state more or less excited and more

or less ionized. The plasma used to improve the regularity of the deposit on

bars with complex shape, energy exchanges are particularly important in the

presence of a reactive gas (see figure 3.6).

The vapor phase is created by electron beam at a pressure less

than 5 · 10-4 mbar, the working potential difference in the

deposition chamber is between 1 and 5 KV.

By introducing a reactive gas in the vapor phase such as

nitrogen or methane, it is possible to produce defined compounds of carbide or

nitride. The main application of this technique is the realization of

deposition of TiN, (Ti, Al)N and TiC.

In competition with the CVD technique, this technique is

widely used for protection against corrosion and erosion, the thicknesses are

limited by some ìm due to the presence of residual compressive

stresses.

|

|

|

Chapter 3: Vapor deposition and thin layer

characterization techniques

|

|

|

|

|

|

|

|

Source

41

Fig.3.6 Schematic representation of physical vapor deposition

by ionic deposition 3.3.2.3. Physical vapor deposition by

sputtering

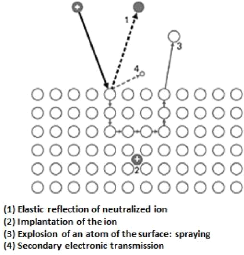

Negative polarization in the order of 1 to 3 kV of an

electrode (target) in the presence of a rarefied argon atmosphere at a pressure

of about 1 to 10 Pa depending on the size of the reactor, leads to the creation

of an electrical discharge between the target and the walls of the reactor. The

walls of the reactor connected to the ground, act as an anode. The Ar + ions

created in the discharge are accelerated in the cathodic cover and acquire the

energy which they release when they impact on the surface of the target. This

can cause the ejection of an atom by transfer of momentum, the implantation of

the incident ion, the reflection of the incident ion neutralized by charge

transfer or the emission of electrons that will serve to maintain the discharge

(figure 3.7).

We can define two main characteristics that govern this

mechanism:

- The spraying rate or yield Y (Table 3.4): it's defined as

the number of spraying atom per incident ion. It grows linearly with the ion

energy, and inversely proportional to the energy of sublimation of the

material;

- The secondary electronic emission coefficient: defined as

the number of electrons emitted during impact with incident ion. Its value is

close to 0.1 for most metals but reaches very high values in the case of many

oxides or nitrides.

42

Chapter 3: Vapor deposition and thin layer

characterization techniques

Fig.3.7 Main mechanisms resulting from the interaction of

an energy ion and a surface

|

element

|

Y

|

element

|

Y

|

element

|

Y

|

element

|

Y

|

element

|

Y

|

|

C

|

0,12

|

Ti

|

0,51

|

Cu

|

2,3

|

Pd

|

2,08

|

W

|

0,57

|

|

Al

|

1,05

|

Cr

|

1,18

|

Zr

|

0,65

|

Ag

|

3,12

|

Pt

|

1,4

|

|

Si

|

0,5

|

Fe

|

1,1

|

Mo

|

0,8

|

Ta

|

0,57

|

Au

|

2,4

|

|

in blue, Metals with very high sputtering yield

|

Table 3.4 Sputtering yield of different elements by argon

ions at 400 eV 3.3.2.4. Magnetron effect

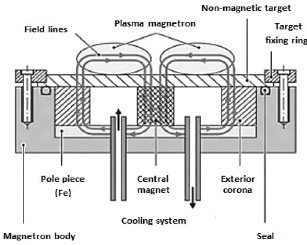

Two main problems result from the diode process. On the one

hand, the low ionization rate of the discharge leads to low deposition speeds

(<0.1 ìm / h) and, on the other hand, the high heat of the sputtered

atoms leads to the synthesis of porous coatings. In order to avoid these two

disadvantages, the target is generally equipped with a magnetron device

consisting of two concentric magnets of opposite polarities (Fig. 3.8). A pole

piece closes the magnetic circuit on one side, while the non-magnetic target to

allow the magnetron effect; it leaves the field lines closed within the gaseous

phase, which affect the trapping of the secondary electrons and thus increasing

their possibility of encountering an argon atom in the context of an ionizing

interaction. Dense plasma is then generated at the gap of the magnets, which

leads, despite

43

Chapter 3: Vapor deposition and thin layer

characterization techniques

heterogeneous erosion of the target, to increase considerably

the discharge current and, subsequently, a deposition speed in the order of 10

ìm / h.

Fig.3.8 Principle of the magnetron device

3.3.3. Physical mechanism of a thin layer

formation

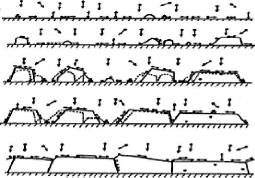

The formation of thin layers by physical vapor deposition is

the result of the condensation of the particles ejected from the target onto

the substrate. It is carried out by a combination of nucleation and growth

processes described in Figure 3.9.

At the moment of impact on the substrate, the incident atoms

lose their kinetic energies and produce the limiting of their ability to

diffuse into the substrate. This is true only if there is no external energy

supplied to these particles by heating the substrate or ion bombardment. Since

they are first adsorbed, they are known as adatoms. Those

adatoms move on the surface until the thermal equilibrium with the substrate is

reached.

During their displacement, the adatoms interact with one

another; creating nucleus called clusters which continue their

displacement by developing and colliding with each other. The clusters continue

to grow in number and size until a nucleation density known as saturation

density is reached.

The next step in the process of forming the thin layer is

called coalescence. The clusters begin to agglomerate with each other by

reducing the surface area of the uncoated substrate. The coalescence can be

accelerated by increasing the mobility of the adsorbed species, for example by

increasing the temperature of the substrate. During this step, new clusters may

be formed on surfaces released by the approach of older clusters. The clusters

continue to grow, leaving only holes or channels of small dimensions between

them. Gradually, a continuous layer forms when the holes and channels are

filled.

44

Chapter 3: Vapor deposition and thin layer

characterization techniques

Fig.3.9 Layer growth process: nucleation and clusters

growth

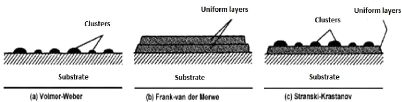

There are three modes of clusters nucleation and growth:

- A cluster called Volmer-Weber (fig.3.10. (a)):

During three-dimensional growth, or Volmer-Weber growth, clusters

form and their coalescence forms a film. This mode of growth is usually favored

when the atoms forming the deposited layer are more strongly bonded to one

another than to the substrate.

- A cluster called Frank-Van der Merwe (fig.3.10 (b)):

The Two-dimensional (2D) growth, or Frank-Van der Merwe growth,

is favored when the binding energy between the deposited atoms is less than or

equal to that between the thin layer and the substrate. So, the films form

atomic layer by atomic layer.

- The mixed type called Stranski-Krastanov (fig.3.10. (c)):

The third mode of growth, called Stranski-Krastanov, is a

combination of the two preceding modes: after two-dimensional growth begins, a

change in growth mode is observed, while clusters formation becomes

energetically favorable.

Fig.3.10 Main growth modes of thin films

3.3.4. Thin film morphology

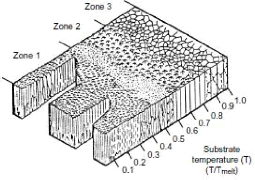

The growth mode of layers as well as the deposition conditions

(substrate temperature, substrate nature, partial gas characteristics, etc.)

influence on the crystallographic orientations and the topographical details of

the clusters.

In fact, several models based on thin film growth approaches

have been developed to study the influence of the deposition parameters on the

microstructure of the layers. The first

45

Chapter 3: Vapor deposition and thin layer

characterization techniques

description of the morphology of thin layers obtained by

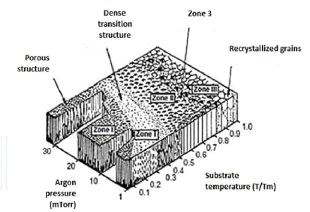

physical vapor deposition was presented by Movchan and Demchishin (fig.3.11)

[MOV69]:

- First zone: the working pressure is greater than or equal to

1 mbar and the deposition temperatures are between 0.1 and 0.2 times the

melting temperature of the deposited metal, this zone is favorable for

applications or wettability of the surface is sought but not suitable for

corrosion resistance or mechanical strength.

- Second zone: is called also the transition zone where the

crystallization of the deposit is very fine with good properties in terms of

resistance to corrosion and adhesion.

- Third zone: where the columnar crystallization is well

identified, this zone is preferred for mechanical applications because of the

good adhesion properties obtained.

Fig.3.11 Movchan and Demchishin structural model

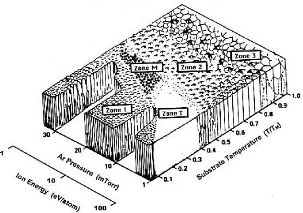

Thornton [THO77] proposes a model that complements the

previous one by considering the argon pressure in the sputtering. Its model

shows a transition zone, called zone T, between zones 1 and 2 (fig.3.12). In

this zone, the grains have a fibrous form without microporosities.

Later, Messier [MES84] showed that the fundamental process

controlling the morphology of the T-zone was not only the gas pressure but also

the effect of the gas pressure on the ionic bombardment of the growing film

surface during the deposition by cathodic sputtering. He proposed a fifth zone

M of morphology consisting of parallel columns with a domed surface

(fig.3.13).

Chapter 3: Vapor deposition and thin layer

characterization techniques

Fig.3.12 Structural modal of Thornton

Fig.3.13 Structural modal of Messier

46

3.4. Methods of microstructural

characterization

After the application of the layer on the sample, this layer

must be characterized. First, we must study its morphology using chemical,

crystallographic and microstructural techniques (Table 3.5), and then we

characterize one or more properties of this deposit (mechanical, optical,

electrical, chemical properties, etc.). These properties are generally studied

with all

47

Chapter 3: Vapor deposition and thin layer

characterization techniques

results of morphological studies, in order to draw a

conclusion either to modify the deposition process or to apply it in

industry.

The greatest difficulty in the characterization phase is that

these techniques are indirect. So, the engineer's art consists in crossing the

results obtained, to constitute a global and synthetic vision of the most

realistic product possible, in order to be able to produce a list of functional

characteristics.

|

Chemical characterization

methods

|

Crystallographic

characterization

methods

|

Microstructural

characterization methods

|

|

- Auger Electrons Spectroscopy

|

|

|

|

(AES)

|

|

- Atomic force microscope

|

|

- Energy Dispersion Microscopy

|

|

(AFM)

|

|

(EDS)

|

|

- Scanning Tunnel microscope

|

|

- Electron Energy Loss

|

- Selected area diffraction

|

(STM)

|

|

Spectroscopy (EELS)

|

(SAD)

|

- Optical Microscope (LM)

|

|

- - Electronic microprobe analysis

|

- X-ray diffraction (XRD)

|

- Scanning electron

|

|

(EMPA)

|

|

microscope (SEM)

|

|

- Raman Spectroscopy (RS)

|

|

- Transmission electron

|

|

- X-Ray Photoelectron spectroscopy

|

|

microscope (TEM)

|

|

(XPS)

|

|

|

Table 3.5 the classification of main morphological

characterization techniques of a thin layer

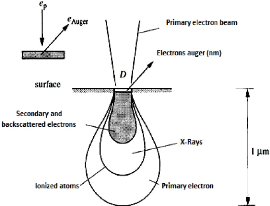

3.4.1. Chemical characterization methods 3.4.1.1.

Auger Electrons Spectroscopy (AES)

Fig.3.14 Distribution of the primary, Auger and backscattered

electrons, as well as X-rays under bombardment of a focused primary electron

beam of a diameter D

48

Chapter 3: Vapor deposition and thin layer

characterization techniques

This technique consists in bombarding the layer with an

energetic primary electrons (3 to 30 KeV), which penetrates into the matter at

depths of the order of some micrometers and excites the atoms of the layer, the

de-excitation can be carried out by emission of the secondary electrons, and of

the Auger electrons after the relaxation.

These electrons are characteristic for each atom, and the

study of their spectrum makes it possible to identify the chemical composition

of the deposit, the atlas of the spectrums of the Auger rays is available in

the literatures.

The AES technique is used to analyze the most superficial

atomic layers for conductive and semiconductive samples.

3.4.1.2. Energy Dispersion Microscopy

(EDS)

This technique involves bombarding the layer by a beam of

primary electrons; this beam can cause the emission of X-rays. The emitted

spectrum breaks down into two radiations: a continuous radiation and a

characteristic radiation which created after an inelastic impact between the

atom and the electron. The characteristic radiation is specific for each

element, and its detection allows for chemical analysis.

3.4.1.3. Electron Energy Loss Spectroscopy

(EELS)

This technique involves exposing sample to a primary electron

beam; some of these electrons will be subjected to inelastic impacts with the

atoms of the sample, which causes the loss of their energy and a weak or random

deflection of their trajectory. This loss of energy can be measured, and the

spectrum can be used to determine the chemical characteristics of the

sample.

3.4.1.4. Electron microprobe analysis

(EMPA)

This technique is based on the analysis of the X-rays emitted

by the atoms of the sample after inelastic impacts with the electron beam. The

X-radiation is sent to a monochromator which is a single crystal having

well-known crystalline planes. This radiation is then diffracted, and the

diffraction angle varies as a function of the wavelength.

3.4.1.5. Raman spectroscopy (RS)

The Raman effect results from the slight change in the

frequency of the monochromatic light projected on the sample, this modification

is caused by the vibrations and / or the rotations of the molecules. The

spectrum analysis of the scattered light gives information on the molecular

composition of the sample, because the spectrums of the vibrations are

characteristic for each molecule.

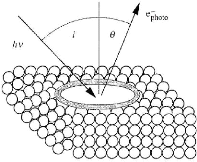

3.4.1.6. X-Ray Photoelectron spectroscopy

(XPS)

Also called ESCA (Electron Spectroscopy for Chemical

Analysis), this technique involves bombarding the sample with X-rays; the

photons y of these rays enter the sample and ionize

the atoms. The photons have kinetic energies E??

which correspond to the ionization energies E

of the different orbits of the atom by the relation:

49

Chapter 3: Vapor deposition and thin layer

characterization techniques

E = h?? - E?? (3.18)

h: Is Planck constant;

The energy of the electrons in each orbit is specific for each

atom, so the knowledge of the energy of the projected photons h??

and the analysis of the kinetic energy of the photons makes it

possible to identify the chemical composition of the sample. The average

analysis depth by this technique is from 1 to 5 nm.

Fig.3.15 Principle of XPS analysis

3.4.2. Crystallographic characterization

techniques

Crystallographic analysis techniques are based on the

principle of X-ray diffraction (XRD) or electron-associated wave (SAD). These

techniques make it possible to determine:

- Crystalline phase composition;

- The orientation and degree of organization of the crystal

grains;

- Stress inside the repository.

3.4.2.1. Selected area diffraction

(SAD)

A primary beam of electrons passes through a thin sheet; the

wave associated with the electrons is submitted to diffraction on the

crystalline planes of the sample. The transmission electron microscope TEM

allows obtaining the image and the spectrum of this diffraction. The SAD

technique makes it possible to obtain the information for very small

crystalline grains.

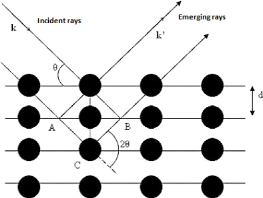

3.4.2.2. X-ray diffraction (XRD)

The X-rays are diffracted on a crystalline plane according to

Bragg's law: A = 2d sin?? (3.19)

The diffracted X-Rays wavelengths vary between ë = 0.071

nm (source with molybdenum anode) and ë = 0.154 nm (source with copper

anode).

Chapter 3: Vapor deposition and thin layer

characterization techniques

The diffraction experiments are done differently for thick

layers (more than 10 ìm) and for thin layers. The thick layers are

tested with a diffractometer in which the radiation source and the detector

move circumferentially around a sample, placed at its center, the radiation

penetrates into the interior of the layer and the signal of the substrate is

low. This technique should not be applied to thin films because the signal of

the substrate would be dominant compared to that of the deposit. In this case,

the surface diffraction technique (GRXD) in which the incident beam interacts

with the surface of the layer at a small angle varying from 1 to 10 ° so

that to have a penetration depth of less than 1 ìm, the detector moves

to obtain the diffracted signal.

Fig.3.16 Bragg law principle

3.4.3. Microstructural characterization

methods

The microstructure analysis concerns the study of the layer

surface (AFM, STM) as well as the study of grains inside the deposit (LM) or

the internal grain morphology (TEM).

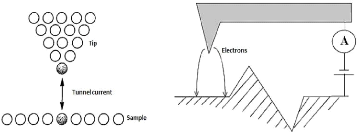

3.4.3.1. Scanning Tunnel microscope

(STM)

The STM is used to characterize the surface of conductive or

semiconductive materials. This microscope has a tip whose end has the size of

an atom.

50

Fig.3.17 operating principle of the STM

Chapter 3: Vapor deposition and thin layer

characterization techniques

The principle (figure 3.17), is to set a distance less than 1

nm (interatomic distance) between this tip and the surface of the sample, which

allows the exchange of electrons and cause an electrical voltage of U = 2mV to

2V, the resulting current is called the tunnel electron current. Since this

current is very sensitive to any changing in the distance between the tip and

the surface, so this distance must be kept constant. This principle allows

obtaining a map with a very good vertical resolution of the surface.

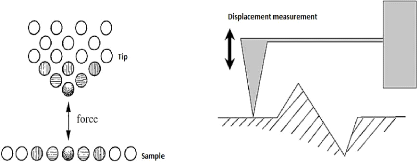

3.4.3.2. Atomic force microscope

(AFM)

Unlike the STM, the AFM was developed to obtain surface

profiles of non-conducting materials. The tip of the probe is equipped with a

small diamond that touches the surface of the layer with a small force varying

between F = 10-6 and 10-9 N to avoid any damage to it.

The diamond is attached to a lever of which while the displacement occurs, the

measurements are made by very sensitive sensors (fig.3.18).

51

Fig.3.18 Operating principle of the AFM 3.4.3.3.

Optical or Light microscope (LM)

The use of the optical microscope requires special preparation

of the layer surface. This microscope allows observing the porosity and the

distribution of the pore size, the size of the unfused particles and their

distributions, the thermal and mechanical deformation of the substrate at the

interface with the deposit, the phase distribution in a composite deposit, etc.

. .

3.4.3.4. Scanning electron microscope

(SEM)

The operating principle of the SEM is the projection of a

primary electron beam which scans the sample surface and which accelerates by a

voltage of U = 1 to 30 kV. The beam of electrons interact with the atoms of the

sample either by inelastic impacts followed by their ionization and by the

generation of secondary electrons with a kinetic energy of E?? < 50 eV

coming from the superficial region of the deposit (some nanometers), or By

elastic impacts with these

52

Chapter 3: Vapor deposition and thin layer

characterization techniques

atoms and the generation of backscattered electrons with a

kinetic energy of E?? > 50 eV coming from the deeper regions

(hundreds of nanometers).

The secondary electrons are detected by a scintillation

detector equipped with a grid carried at the positive potential to attract

these electrons at low energy. The backscattered electrons are detected by a

semiconductor detector.

3.4.3.5. Transmission electron microscope

(TEM)

The operating principle of this microscope is the emission of

a beam of primary electrons passing through the sample. The image in this

microscope is obtained by electrons that have not interacted with the sample.

The electrons are accelerated by a voltage of several hundreds of kV to be able

to cross slides, which must have a thickness less than 100 to 200 nm.

3.4.4. Mechanical characterization 3.4.4.1.

Hardness

Three types of hardness are defined depending on the depth of

indentation (Table 3.6). The loads used depend on the type of hardness. In

nanohardness these charges range from some micronewtons to several hundredths

of millinewtons, while microhardness requires loads ranging from a few tens of

millinewtons to a few Newtons, in macrohardness the loads range from a few

Newtons to several tens of Newtons.

|

nanohardness

|

microhardness

|

macrohardness

|

|

Depth of indentation (rim )

|

0.001 - 1

|

1 - 50

|

50 - 1000

|

Table 3.6 Types of hardness

The use of each type of hardness depends on the material being

tested, so the nanohardness is used to characterize thin layers with

thicknesses of less than one micrometer, whereas the microhardness used to

study certain surface treatments such as shot blasting or Thermo-chemical

treatments (carburizing, nitriding, etc.). The macro hardness is used to

measure the hardness of the steels after a heat treatment for example.

With the appearance of nanohardness since 1990, it was

possible to understand different mechanical characteristics of materials at the

sub-micron scale. However, although this test is fairly simple to carry out in

principle, its technological implementation remains delicate, and the

interpretation of the results is not simple. Indeed, it is a test, although

extremely powerful, which requires a particular attention during the testing,

and the analysis of the information.

The nanohardness test consists in the simultaneous measurement

of the force F applied to the indenter and of its

penetration h into the material under investigation. The representation

F = f (h) for the charge and the discharge

constitutes the nanoindentation curve.

The inverse analysis by finite elements analysis of the

indentation curves allows, to some extent, to have mechanical properties such

as: modulus of elasticity, hardness tensile strength, etc.

53

Chapter 3: Vapor deposition and thin layer

characterization techniques

The interpretation of the measured characteristics (and in

particular the hardness) by the nanoindentation test requires simultaneous

consideration of the ISE (Indentation Size Effect) and the exact shape of the

indenter tip (Berkovich or Vickers), and without forgetting the effects of

roughness.

We can observe hardness variations of the order of few

percents due to the presence of internal stresses in the materials tested, this

is particularly true for thin films.

3.4.4.2. Adhesion of coatings

It is assumed that the adhesion of protective film is an

indispensable condition, because of that, the deposition of a coating film is

always preceded by a mechanical and / or chemical treatment intended to clean

and activate it in order to optimize the adhesion of the film to the substrate.

It is also often the practice to deposit an intermediate film (bonding layer)

between the substrate and the final coating, for example, a layer of silicon is

deposited on steels before being coated with a DLC layer.

For the characterization there are two main families of

techniques: non-destructive and destructive techniques. The first uses an

optical or acoustic probe that explores the coated material and detects any

defect or inhomogeneity (cracks, porosities, bubble etc.) at the film-substrate

interface. The most used amongst these methods are the ultrasonic methods.

Destructive techniques can be divided into two categories:

- Techniques used for ductile or weakly adherent coatings

(paints, varnishes, polymers, etc.): like the peeling test, the swelling

test...

- Techniques for metallic or ceramic coatings or when the

adhesion is strong: as the scratch test.

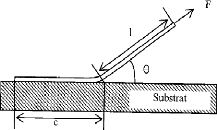

- Peeling test

This test consists in applying a force F, at an angle

è, to a band of length b, deposited on a substrate (Figure. 3.19). This

force increases gradually over time until the force F??

corresponds to the initiation of the flow of the film. The operation

is then continued at constant speed until the complete flow. At the end of the

test, it is necessary to check the condition of the uncoated strip and that of

the substrate in order to check that there is no elongation or plastic

deformation and that all the energy expended during the flow of the band

interface was used to break the bonds at the substrate-band interface.

The rate of release energy is given by:

G = (F??? ?) (1 - ????????) [??m-2]

(3.20)

Chapter 3: Vapor deposition and thin layer

characterization techniques

Fig.3.19 principle of the peeling test

54

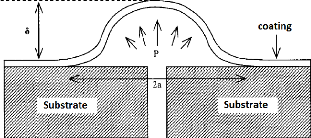

- Blister Test:

This test consists in making an opening in the substrate in

such a way to retain the initial thickness of the film. A pressure P on the

deforming film is then applied using an incompressible fluid. The film will

begin to swell progressively up to a certain critical height ????

corresponding to a pressure P?? and then begin to peel

off from the substrate (Fig.3.20).

The rate of return of energy is given by:

G = ??P?????? (3.21)

?? : Constant having a value between 0.5 and 0.65;

Fig.3.20: Principle of the Blister Test

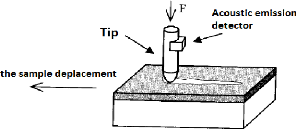

- Scratch Test

This test consists in applying, perpendicularly to the surface

to be tested, a sharp Rockwell-type indenter (cone with an angle of 120 °

and a radius of curvature of 200 ìm) supporting a load of between 1 and

200 N which increases linearly over time with a loading rate of 10?? ·

m????-1. When the indenter sinks into the surface of the

material, it is made to slide with a velocity of 10 mm.

m????-1 (fig.3.21).

55

Chapter 3: Vapor deposition and thin layer

characterization techniques

Fig.3.21 Principle of Scratch Test

3.4.4.3. Residual stresses in the

coatings

In the production of a high-temperature coating ( PVD or CVD),

at the time of return to ambient temperature, due to the difference in the

coefficient of thermal expansion between the coating and the substrate,

internal stresses can appear in the film, and the deposition-substrate assembly

can deform if the substrate is sufficiently thin (some tens to a few hundreds

of micrometers thick), in this case the direction of convex or concave

deformation indicates, whether they are tensile or compressive stresses .

The internal stresses have an important role because they can

influence both the hardness of the coating, its adhesion to the substrate and

also its resistance to wear and cracking.

The two main techniques used for the determination of internal

stresses are X-ray diffraction and the Stoney method. The two methods consist

in reducing the thickness of the substrate by machining to such a value in

which the action of the residual stresses is manifested.

- The Stoney method (the determination of the

internal stresses by measuring the radius of curvature):

From this technique, the mean internal stresses ó can be

calculated using the expression:

h?? 2????

?? = ????h??(1 - ????) (3.22)

h??, ????, ????: Are the thickness, the Young's modulus and the

Poisson's ratio of the substrate;

h??: The coating thickness; ??: The radius of curvature.

This relation makes sense only when the ratio (h??/h??) is of the

order 5 to10 % .

3.5. Thin films deposits properties

PVD and PACVD thin films are used to improve friction and wear

resistance. Table 3.7 gives the main mechanical and tribological

characteristics of the layers produced:

56

Chapter 3: Vapor deposition and thin layer

characterization techniques

|

coating

|

TiN

|

(Ti,Al)N

|

TiCN

|

CrN

|

DLC

|

|

Color

|

Yellow gold

|

black

|

purple

|

silver

|

back

|

|

Hardness (HV)

|

2300 à 2500

|

2500 à 3200

|

3000 à 3400

|

1800 à 2200

|

3500 à 5000

|

|

oxidation résistance (°C)

|

400

|

800

|

300

|

600

|

400

|

|

Elaborating temperature (°C)

|

250 à 400

|

450

|

450

|

600

|

200 à 400

|

|

thickness (um)

|

2 à 5

|

2 à 5

|

2 à 6

|

3 à 8

|

1 à 4

|

|

Dry friction on 102 Cr6

|

0.55 à 0.65

|

0.50 à 0.60

|

0.45

|

0.40 à 0.55

|

0.05 à 0.07

|

- The coating of (Ti,Al)N is the most resistant to oxidation, so

it will be used under severe thermal conditions.

- The DLC coating is the one which have the best tribological

characteristics because of the presence in its microstructure of a large

proportion of graphite bonds; it is therefore used for delicate lubrication

conditions.

- The TiCN coating has a good hardness property, with good

conductivity; it will therefore be used with strong mechanical stresses such as

steels.

- The CrN coating has good ductility and good resistance to

oxidation.

Chapter 4

Experimental Process

54

Chapter 4: Experimental Process

4.1. Determination of the sample grade

The piston used in our study as a substrate is HATZ E780. The

materials used to make this piston are: Cast iron and aluminium-silicon

eutectic alloy, the main production processes are: melding, forging

[GER/https].

Fig.4.1: The piston HATZ E780 studied

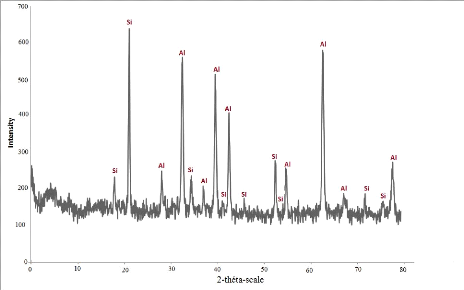

According to the XRD analysis it can be ensured that the material

used for piston manufacture is the eutectic Al-Si alloy fig. 4.2.

Fig.4.2: XRD spectra of a sample of the piston HATZ

E780

55

Chapter 4: Experimental Process

The silicon content in aluminium for a eutectic Al-Si alloy is

varied between 11.7 % and 14.5 % the average

value is generally 12.5%. The most commonly used eutectic

alloys for the manufacture of pistons are given in table 4.1

[EUR/http]:

|

Continent

|

4032 (AW-AlSi12,5MgCuNi)

|

4047A (AW-AlSi12 (A))

|

4045 (AW-AlSi10)

|

|

Si %

|

11-13.5

|

11.0-13.0

|

9.0-11.0

|

|

Fe %

|

1.0

|

0.6

|

0.8

|

|

Cu %

|

0.8-1.3

|

0.3

|

0.3

|

|

Mn %

|

|

0.15

|

0.06

|

|

Mg %

|

0.8-1.3

|

0.1

|

0.05

|

|

Zn %

|

0.25

|

0.2

|

0.1

|

|

Ti %

|

|

0.15

|

0.2

|

|

others %

|

0.2

|

0.2

|

0.2

|

|

Al %

|

Rest

|

Rest

|

Rest

|

Table 4.1: most commonly used eutectic alloys for the

manufacture of pistons

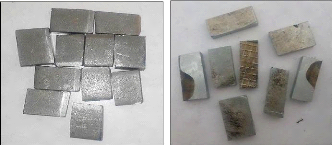

4.2. Preparation of samples

4.2.1. Samples Cutting

The piston with cylindrical shape is cut in the workshop in order

to obtain samples with dimension of (20×10×6) mm; the cutting

operation is divided into two stages:

First stage: Consists of piston separation in

two sections (Head and skirt) By means of a metal chainsaw

Second stage: Consists in cutting the upper part

of the piston obtained by the preceding method with the aid of a hacksaw into

samples of well-defined size.

Fig.4.3: cutting samples, on the left stainless steel, on

the right aluminium

56

Chapter 4: Experimental Process

4.2.2. Samples polishing

In the process of surface preparation operations, polishing is

essentially a finishing operation, the purpose of which is to:

- reduce roughness and surface topology by eliminating surface

defects such as microcracks, porosities and inclusions.

Using a MECAPOL 230 polisher (fig.4.4), The 304 stainless steel

substrates and the Al-Si substrate are polished, using abrasive papers with

particles size varied from (200 to 1200) it is a kind of sandpaper, but with a

larger particle size Fine and controlled.

Obtaining of the polished surface finish is done progressively

(from the big size to the small one) in the presences of the water for the

cooling and the evacuation of the debris.

Fig.4.4 : MECAPOL 230 polisher

Characteristics of the device

- The polishing head makes it possible to process up to 6 samples

Ø 50 mm flanged in a plate by central pressure.

- Pressure force between 0.5 à 30 daN.

- Time between 10s to 99 minutes.

- Rotating speed between 20 à 600 rpm/mn.

4.2.3. Chemical cleaning

The purpose of chemical cleaning is to remove contamination or

impurities formed after polishing to ensure good adhesion of the deposit.

The samples are immersed in an acetone bath for about 5

minutes; then rinsed with distilled water and then dried with the aid of

compressed air.

4.3. Thin film elaboration process

In our work, we will deposit a thin layer on three types of

samples with different substrates in

order to better characterize the layer obtained:

- Four samples of a substrate obtained from an Al-Si alloy piston

HATZ E780;

- Four samples of 304 stainless steel substrate;

- Five samples of a 304 stainless steel substrate on which an

Al-Si layer is deposited;

57

Chapter 4: Experimental Process

- In four of the previous five samples, a layer of Ti-W-N is

deposited.

We use the PVD sputtering technique to deposit thin layers of

Ti-W-N on Al-Si, stainless steel 304 and stainless steel with intermediate

layer of Al-Si, the evaporation technique was used to create the intermediate

layer

4.3.1. Description of PVD sputtering installation and

working parameters

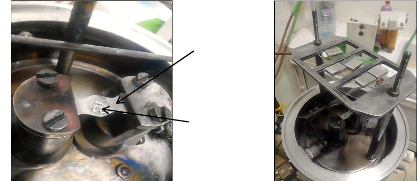

Fig.4.5. PVD sputtering installation of the CDTA

1) Bottle of nitrogen gas - 2) Nitrogen passage line - 3)

Primary pressure gauge - 4) secondary pressure gauge - 5) Primary and secondary

pump ignition switches - 6) Secondary Pump Cooling Water Pipe - 7) deposition

reactor - 8) Secondary diffusion pump - 9) Pallet primary pump - 10) Gas

pressure control valve (nitrogen and argon) - 11) Throttle valve - 12) Power

supplies

The deposition chamber is cylindrical in shape, with a high of

230 mm, diameter of 210 mm, the interelectrode distance is 45 mm, and the lower

part of the chamber is connected to the pumping system.

The primary pump is an Alcatel-type pump that can achieves a

vacuum of up to2 · 10-2???????? (2.67 ·

10-2????????) And a flow rate of0.5 à 70

????3 /?? .

The secondary diffusion pump used allows a vacuum to reach

10-5???????? (1.33 · 10-5????????) And a

flow rate of 250 ????3 /?? .

Chapter 4: Experimental Process

The primary pressure gauge is Priani type, it measures pressures

up to 10-3Torr (1.33 · 10-3 mbar). The secondary

pressure gauge is a Penning type gauge, the measured pressure can

reach10-5Torr (1.33 · 10-5 mbar).

The power generator supplies the system with a maximum electrical

power of 20 Watt, a voltage of 2 kV and an electrical current of 10 mA.

The working parameters are:

- The application of argon alone for 5 minutes with a pressure of

9.5 · 10-2Torr ; (0.127 mbar). Argon ions spray directly the

target, allowing surface cleaning;

- The introduction of nitrogen into the plasma for one hour with

the pressure of 0.1 Torr (0.133 mbar);

- The percentage of nitrogen introduced into the plasma is 5%

;

- The working voltage is 2 kV.

|

a)

|

|

b)

|

|

|

Fig.4.6: the deposits obtained on the PVD sputtering

installation:

- a) on Al-Si,

- b) on stainless steel,

- c) on stainless steel with

intermediate layer of Al-Si

|

c)

|

b)

|

58

4.3.2. Description of PVD evaporation installation

and working parameters

The working parameters are:

- The limiting pressure of the primary pallet pump is 10-2

mbar ;

- The limiting pressure of the secondary diffusion pump is 3

· 10-5 mbar ;

- in order To have a thin layer on stainless steel similar to

aluminium-silicon eutectic alloy (of 12.5 % Of silicon content see chapter 2),

il faut Put on the crucible 60 mg of powder contains 52.5 mg of the aluminium

powder and 7.5 mg of the silicon powder.

59

Chapter 4: Experimental Process

Fig.4.7: The PVD by evaporation installation of

CDTA

1) Primary pressure gauge - 2) Secondary pressure gauge - 3)

Primary and secondary pump ignition switches - 4) Secondary Pump Cooling Water

Pipe - 5) Deposition reactor - 6) Secondary diffusion pump - 7) Pallet primary

pump - 8) Throttle valve - 9) To power supply

a)

b)

The crucible of the evaporator

Al-Si powder To evaporate

Fig.4.8: Inside the reactor chamber: a) Al-Si powder on the

crucible, b) The samples of stainless

steel on the substrate port

60

Chapter 4: Experimental Process

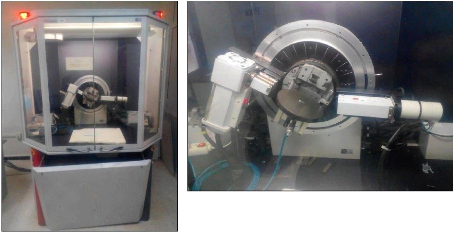

4.4. X-ray diffraction

An indispensable complement to elemental chemical analysis for

the identification of compounds, X-ray diffraction allows the fine

characterization of massive crystallized materials

Fig.4.10: Our sample at the interior of the

diffractometer

Fig.4.9: Diffractometer D8 ADVANCE of CDTA

4.4.1. Characteristics of the device

· The diffractometer uses the BRAGG-BRENTANO assembly;

· Source (anticathode) of copper;

· Point scintillation detector;

· Acquisition range between 0 ° and 90 °. With

precision of steps up to 0.01°;

· Grazing incidence configuration, with a minimum angle of

incidence of 0.1 °;

· Eva operating software.

4.4.2. Working Principle [CDTA/http]

X-ray diffraction gives access to many information contained

in the arrangement of atoms within a crystallized material and The 3D

geometrical type of arrangement (network), the distances between atoms (mesh

size, typically a few Å) which constitute schematically a "unique"

identity card for each compound.

The BRUKER D8 Advance diffractometer is equipped with a

BRAGG-BENTANO geometry goniometer. In this type of diffractometer, an incident

monochromatic X-ray beam is diffracted by the sample at certain specific

angles, According to Bragg's law: 2dhkl

sinè = A, in which dhkl Refers to the

interreticular distance of family plans (hkl), è Is the angle of

incidence taken from the surface of the planes (hkl) ,ë The wavelength of

the scattered photons.

61

Chapter 4: Experimental Process

As Lambda does not vary during a measurement, it is enough to

vary the angle Theta to locate all diffraction angles. By means of a converter

- a scintillation counter, the intensity of each point of the measurement is

thus observed.

When the X-ray beam is diffracted, its representation is a

peak. A Theta scan produces an X-ray diffraction pattern.

The recording of the signal by a suitable detector makes it

possible to visualize the angles and Intensities of the diffraction peaks

obtained. The indexing of these peaks is carried out using specific databases

that have more than 350 000 records. Allowing the identification of the

compound (s).

4.5. Raman Spectroscopy

4.5.1. Principle of RAMAN spectroscopy

During the interaction of a light beam with the material,

several phenomena can occur. A part of the light beam is reflected, a part is

diffused and a part can be transmitted through the sample (figure 4.11). During

propagation in a dense medium, different phenomena appear: refraction,

absorption, diffusion, and possibly other non-linear effects. The absorption

may then induce photoluminescence or non-radiative de-excitation processes.

The scattering of light is manifested by the deflection of a

part of the light beam in multiple directions. The majority of the scattered

light is of the same energy as the incident light. This phenomenon of elastic

diffusion is called Rayleigh scattering. However, a small portion of the

scattered light (about one photon out of 106) present gain or loss of energy

relative to the incident light. This is the phenomenon of Raman scattering. In

a classical approach, this phenomenon of inelastic diffusion is explained by

the creation of an induced dipole which oscillates at a frequency different

from that of the incident light. Indeed, under the action of a monochromatic

electromagnetic wave of frequency ù whose electric field oscillates

according to:

??= ??0 cos(????) (4.1)

Fig.4.11: Spectrometer Raman HORIBA of CDTA

62

Chapter 4: Experimental Process

The Stokes diffusion and the anti-Stokes diffusion would be of

the same intensity. However, experimentally the intensity of the Stokes

diffusion is always (outside resonance) higher than that of the anti-Stokes

diffusion.

4.5.2. The information accessible by Raman

spectrometry

The information provided by Raman spectroscopy is relatively

extensive:

- Identification of phases or chemical compounds ·

- Characterization of materials ·

- Determination of the molecular structure ·

- Study of amorphous and crystalline systems.

The Raman spectrum of a compound indicates both the type of

binding of a compound and its crystalline structure.

4.6. Scanning electronic microscope (SEM)

The scanning electron microscope provides surface images of

virtually all solid materials at scales ranging from the magnifying glass (x10)

to that of the transmission electron microscope (x 500,000 or more).

Conventional SEM operates in an ordinary vacuum (10-5 to 10-6

mbar); The samples may be massive, ranging in size from a few ìm

(particles) to about tens of cm in diameter, or even more (industrial samples).

They must endure the vacuum. The preparation is generally simple.

The SEM at low pressure allows observation in a vacuum of up

to 30 mbar, making it possible

fig.4.12: scanning Electronique microscope JEOL JSM 6360LV de

CDTA

Chapter 4: Experimental Process

to examine moist or oily samples, insulators without prior

metallization (ceramics, corroded metals).

Characteristics of the device

? A maximum resolution of 50 nm.

? The SEM is coupled to the EDS for the elementary

microanalysis.

? Maximum voltage 30 kV.

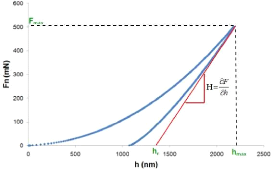

4.7. The nanoindentation

Fig.4.13: The nanoindentation device CSM_NHT of CDTA

The indenter used on our characterization equipment CSM_NHT

(Nano-Hardness Testers is a Berkovich indenter (pyramidal with triangular base

geometry). We can apply a normal force between 0.3mN and 500mN.

|

h

cos65.27° = b

a = 2v3 h ??a??65.3°

|

|

63

Fig.4.14: The geometry of Berkovich Point

Chapter 4: Experimental Process

64

Fig.4.15: the footprint of the Berkovich tip

During an indentation test an acquisition system records the

applied force as a function of the penetration depth of the tip. These two

parameters are measured during a charge phase and a discharge phase. The result

is a load-displacement curve.

The two main properties measured by the nanoindentation are

the modulus of elasticity (E) and the hardness (H). The model used for the

calculation of these two properties is that developed by Oliver and Pharr.

According to this model the hardness is given either geometrically (fig.4.16)

or analytically by:

????????

H = (4.2)

????

Fig.4.16: The determination of the hardness from the

charge-discharge curve

Fmax : Maximum applied load;

Ac : The contact area between the indenter and the

sample which is given in the case of a Berkovich indenter by:

65

Chapter 4: Experimental Process

A?? = 24,56 · hC 2 (4.3)

????????

hC= h?????? - ??· (4.4)

??

???? 2

?? = ??h = · ???? · vAC (4.5)

vit

Er : reduced Modulus of elasticity.

The modulus of elasticity of material is given by:

?? = (1 - v2) ( ???? · ???? )

(4.6)

????(1 - v??2) - ????

ui: Poisson's ratio of the indenter; u:

Material Poisson's ratio;

Ei : Modulus of elasticity of the indenter.

In our nanoindentation tests, we used the Oliver-Pharr model with

the following parameters:

- Spherical diamante Berkovich indenter ( r =

10ìm) in diameter

- approaching speed: 2500 nm/min

- Time of charge and discharge: 10.0 s

- Linear load increment

- Slope to contact: 80%

- Load Speed: 2.00 mN/min

- Speed of discharge: 2.00 mN/min

- Material Poisson's ratio u = 0.30

This device is equipped with an optical microscope to select the

area to be indented. An X-Y

motorized table with a repositioning accuracy of 1 ìm

allows the programming of complex

indentation networks.

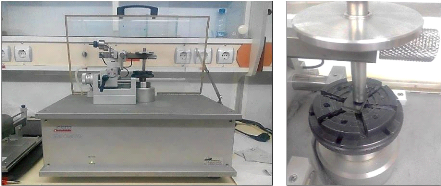

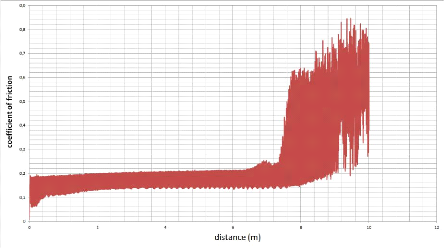

4.8. The tribometer analysis

On the CSM tribometer (fig.4.18), a ball, a tip or a plane is

placed in contact with the surface of the sample under a predetermined load.

The device is mounted on a lever arm, and associated with a displacement

sensor.

The coefficient of friction is determined during the test by

measuring the deflection of this elastic arm. The wear rates for the ball and

the pawn are calculated by determining the loss of volume during the test. The

formula for determining the wear rate WS is given by:

??

????= ?? · ???? (4.7)

66

Chapter 4: Experimental Process

??: The volume of lost matter

(mm3) ;

D: The covered distance (mm)

;

F??: The normal force applied to the sample

(N).

fig.4.17 : Tribometer of the USTHB

The volume of the waste material is calculated by the

formula:

?? = 2??R [r2 aresi?? (d2r) -

(4d) · v4r2 - d2] (4.8)

R: Radius of the wear track

(mm);

r: Radius of the ball (mm);

d: Width of the wear track

(mm).

Tribometer analysis facilitates the study of friction

mechanisms for a wide variety of material couple with or without lubricating

agent. In addition, the control of test parameters such as speed, contact

pressure, frequency, test duration and environmental parameters make it

possible to reproduce the actual stresses of use of these

materials.

Instruments can provide rotational or alternative

movement of the sample. A particular point of these instruments is based on the

possibility of interrupting the test as soon as the coefficient of friction

reaches a predefined value or, when a number of cycles is realized. In

addition, the tribometer is equipped with a containment enclosure in order to

use the instrument under controlled atmospheric temperature

conditions.

The Tests performed by tribometer conforming to ASTM G99

& DIN 50324.

The specifications of the CSM tribometer are:

67

Chapter 4: Experimental Process

|

Nano

|

Micro

|

|

Normal Strength Range

|

50 ìN - 1 N

|

until 60 N

|

|

Maximum tangential force

|

10 ìN - 1 N

|

10 N

|

|

Maximum temperature

|

-

|

1000 oC

|

|

Rotation speed

|

1 - 100 rpm

|

0.3 - 500 rpm

|

|

Rotating test radius

|

30 ìm - 10 mm

|

30 mm

|

|

Linear travel speed

|

10 - 500 ìm

|

60 mm

|

|

Length of linear travel

|

Until 10 mm/s

|

until 100 mm/s

|

|

Frequency

|

0.1 - 10 Hz

|

1.6 Hz

|

|

Penetration depth measurement

|

20 nm - 50 ìm

|

until 1.2 nm

|

Table 4.2: The specifications of the CSM tribometers

The characteristics of our work:

- Geometry of the tip: Ball;

- Material of the tip: alumina????2??3 ;

- Radius of the ball: 3.00 mm;

- Linear speed: 0.50 cm/s;

- Normal load: 1.00 N;

- Stop condition: 10.00 Meters travelled or if ii > 1.00 ;

- Temperature: 20.00 °C ;

- Humidity: 40.00 %.

4.9. Electrochemical techniques

4.9.1. Equipment

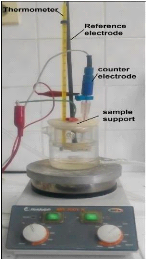

The polarization measurements were carried out in a

three-electrode glass cell: a working electrode, a platinum counter electrode

and a saturated calomel reference electrode (SCE). This cell, shown in figure

4.18, is designed to maintain a fixed distance between the three electrodes.

The passage of the current in the cell is carried out through the

counter-electrode.

68

Chapter 4: Experimental Process

Figure 4.18: the Cell used in electrochemical test

Electrochemical measurements were conducted using a

computer-controlled, potentiostat, model parstat 4000 (Fig.4.19).

Fig.4.19: Assembly for electrochemical testing

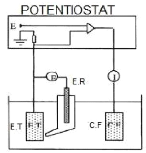

4.9.2. Establishment of EVANS diagrams

The purpose of the EVANS diagram is to rapidly obtain, by a

laboratory measurement, the corrosion rate and the corrosion current density

denoted icorr from the polarization curves

69

Chapter 4: Experimental Process

Fig.4.20 Diagram of the electrochemical cell

The potential measurement is carried out in a given aggressive

medium at a given temperature by means of a potentiostat to which are connected

three electrodes.

? The working electrode E.T constituted by the metal

studied,

?

· The reference electrode E.R which serves as a

reference for the dissolution potential, ?

· The counter electrode

C.E, which is a platinum electrode used to drain the major part

of the current flowing through the circuit when the working

electrode is subjected to an

overvoltage.

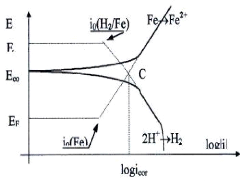

4.9.3. Diagram E=f (log/i): EVANS Diagram

Fig.4.21: a polarization curve modal

To measure the corrosion current density, the representation E

= f (i) is modified, we switch

coordinates to E = f (log / i) or EVANS

diagram in order to linearizes the polarization curve and

Chapter 4: Experimental Process

makes it possible to determine Experimentally the value of

corrosion current density icorr. THE CURRENT is obtained by

extrapolating the linear parts of the anodic and cathodic polarization curves.

This point of assistance, in cases where it is quite clear, gives access to the

characteristics of corrosion (corrosion potential and the corrosion current

density), these two linear parts, respectively called the anodic and cathodic

Tafel branches.

We see clearly on this diagram the Tafel domain in which the

potential varies linearly with the logarithm of the intensity according to the

equations of Tafel

For the anodic process:

i

(4.9)

i0(Fe)

i

(4.10)

i0(H2/Fe)

E = EFe + ba log For the cathodic process:

E = EH + bC log

70

EFe,i0(Fe),EH, i0(H2/Fe) are respectively The

equilibrium potentials and the exchange current of the couples Fe2+/Fe et H+/H2

; ba et bc Are the Tafel constants of oxidation and

reduction, (ba>0)

This graphic construction therefore provides access to these two

important corrosion data. The calculation of Tafel's equations is based on

equality:

i i

Ecorr = EFe + ba log i0(Fe)= EH + bC log

i0(H2/Fe) (4.11)

Chapter 5

Analysis of the results

Chapter 5: Analysis of the results

72

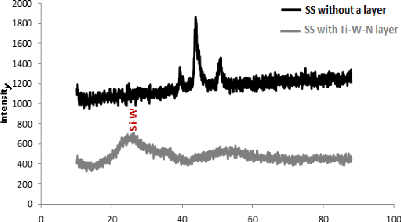

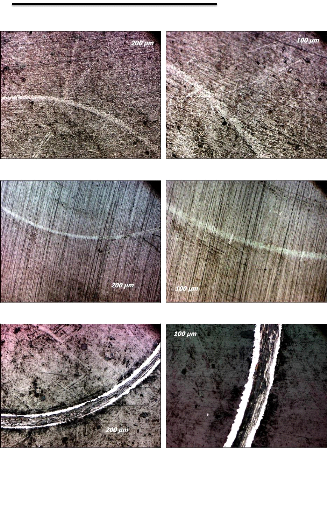

5.1. Analysis of XRD results

- Stainless steel bars:

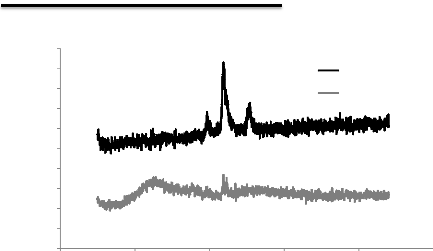

The phases of the thin film were evaluated by the XRD analysis,

and the results are shown in the figure 5.1.

We can see that the deposited layer is an amorphous layer which

does not have a crystallographic alignment with a random orientation of the

grains, so it is inaccessible by X-ray diffraction.

Fig.5.1: XRD spectra of the Stainless steel bars with and

without a layer of Ti-W-N

According to fig. 5.1, a bump can be observed on the angular

value 2è = 23.5°, which corresponds to tungsten silicon (Si-W) in

its amorphous form, which is requiring a subsequent heat treatment to obtain

the crystal structure of layer.

Chapter 5: Analysis of the results

2000

Fe y

vierge

SS without a layer

ss evapo Al-Si+ Ti-W-SS with double layer

1800

1600

1400

1200

1000

800

600

400

200

0

Intensity

Si-W

Fe y

Fe á

73

0 20 40 60 80 100

2-théta-scale

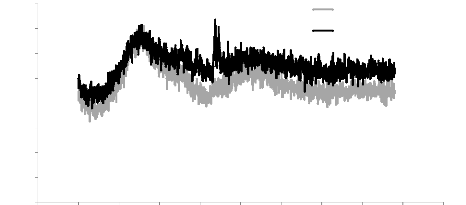

Fig.5.2: XRD spectra of the Stainless steel bars with and

without double layers of Al-Si and Ti-W-N

In the XRD spectra of fig.5.2, we can see again the bump

correspond to the silicon of tungsten (Si-W) at 2è = 23.5

°, we notices also iron peaks belonging to the substrate

which are iron á in 46 ° and iron y at 44

°, which means that the covering of the surface is not perfect and the

formation of an amorphous layer.

SS withTi-WN Ti

-W-N layer

ss evapo AlSi+ TiWN

SS with Al-Si and Ti-W-N double

layers

700

600

500

400

300

200

100

0

Intensity

800

0 10 20 30 40 50 60 70 80 90 100

2-théta-scale

Fig.5.3: XRD spectra of the Stainless steel bars with double

layers of Al-Si and Ti-W-N and with a layer of Ti-W-N

74

Chapter 5: Analysis of the results

Figure 5.3 shows that the intermediate layer deposited by

evaporation between the substrate and the Ti-W-N layer influences in the layer

diffraction properties in a manner which permits the appearance of peaks

corresponding to the substrate.

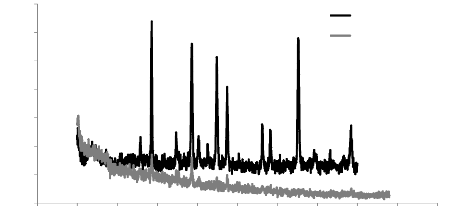

- Aluminum bars:

The diffraction spectra of Ti-W-N layer are shown in figure

5.4.

700

l-i vierge

Al-Si without a layer

Ti-W-N

Al-Si with a Ti-W-N layer

600

500

400

300

200

100

0

Intensity

0 10 20 30 40 50 60 70 80 90 100

2-théta-scale

Fig.5.4: XRD spectra of Aluminum-Silicon bars with and

without a layer of Ti-W-N

The spectra obtained by the XRD analysis of the Ti-W-N layer

on the aluminum substrate shows that a layer with peaks similar to that of the

substrate with an amorphous structure was formed.

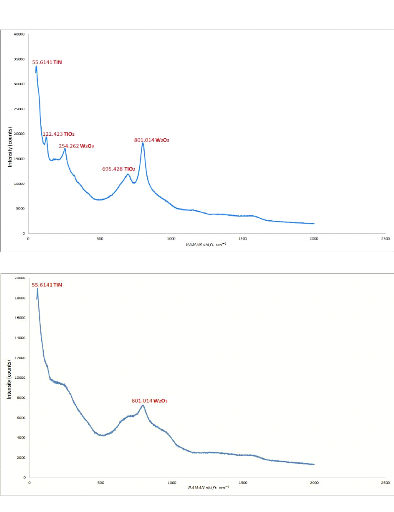

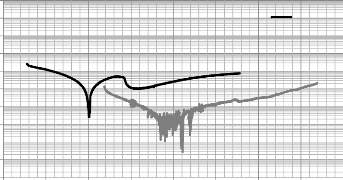

5.2. Analysis of RAMAN results

The results obtained by the RAMAN on the Ti-W-N layer for

different substrates are given by the following curves:

Chapter 5: Analysis of the results

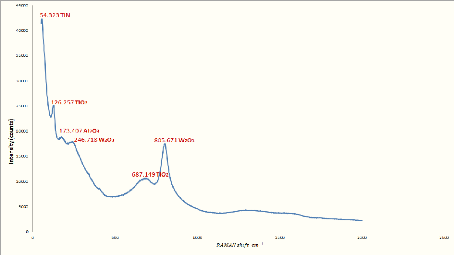

Fig.5.5: RAMAN specter of Al-Si bar with Ti-W-N layer

Fig.5.6: RAMAN specter of stainless steel bar with Ti-W-N

layer

75

76

Chapter 5: Analysis of the results

Fig.5.7: RAMAN specter of stainless steel bar with double

layers of Al-Si and Ti-W-N

It is good to notice that the spectrum obtained for different

bars are almost the same, which means that the same elements have been observed

in the deposited layer for different substrates.

We can identify the spectrums peaks as the following:

- Peaks with the wavenumber 125 ????-1 and

675 ????-1 can be corresponded to titanium dioxide

????02 peaks [IOP/http];

- Peak with a wavenumber close to 62.5

????-1 can be corresponded to a titanium nitride ??????

peak [CHE94];

- Peak with a wavenumber close to 807

?`??-1 can be corresponded to a tungsten oxide

W203 peak [COU64];

- Peak with a wavenumber close to 172 172

????-1 observed in the spectra of stainless steel with

double layers of Al-Si and Ti-W-N can be corresponded to an aluminum oxide

????203 peak [AND02].

From the RAMAN spectrum results, it can be said that our layer

contains titanium Ti, tungsten W and nitrogen N, in the form of tungsten oxide,

titanium nitride and titanium dioxide. All of these peaks (except the

????02 peak in stainless steel substrate) are observed in different

bars.

In the contrary of the XRD results in which amorphous results

are obtained, the RAMAN results are identified all the elements of the thin

layer, which can be explained by the operating principle of each instrument.

The XRD gives results for a crystallographic analysis, so it allows us

essentially to determine the crystalline composition of the layer, which is

practically difficult without a recrystallization of the deposition by an

appropriate heat treatment.

77

Chapter 5: Analysis of the results

RAMAN, on the other hand, is used for chemical analysis. It

allows us directly to observe the chemical composition by the diffusion of the

light at the frequency of the radiation caused by the vibrations of the

molecules.

5.3. Morphological analysis

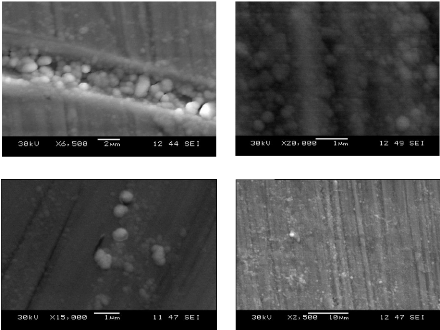

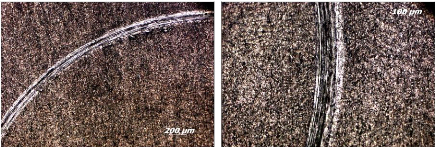

Figure 5.8 shows pictures from the Scanning Electron

Microscopy of a stainless steel bar with the double thin layer of Al-Si and

Ti-W-N.

In the picture b) we observe the formation of a layer made up

with a small nanoparticle of the order of 50 nm in diameter, and particles of

large diameter which can reach 500 nm incorporated in the surface, the

interaction of these particles creates a form of deposition called the

clusters, those clusters collide one another in order to increase their number

and size until the coalescence density where the agglomeration commences, and

the uncoated substrate surface reduces.

a) b)

c) d)

Fig.5.8: SEM pictures, magnification of the double layers

Al-Si and Ti-W-N on stainless steel with apparition of

nanoparticles

78

Chapter 5: Analysis of the results

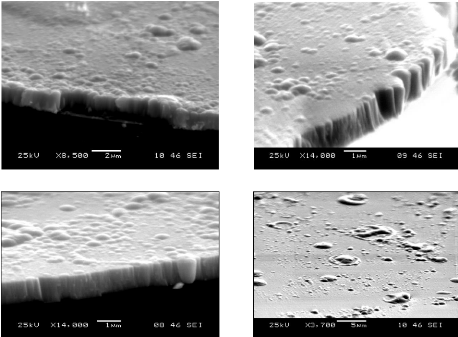

The morphology and the topography of the layer were studied by

the SEM on a cross section of a silicon bar with the thin layer (fig.5.9). The

cross section of the bar shows a columnar structure terminating with domes at

the surface, with grain diameter between 50 and 400 nm.

The mean thickness measured is about 1.1 rim, which lasted one

hour of deposition, what means that the growth rate is equal to 0.30 nm/ s.

That rate is a very large, which means that the deposition is not an atom by

atom layer. It is reasonable to assume that non-uniform nucleation at the

substrate surface at the beginning of deposition is the main cause of the

nonuniform growth of the layer, which cause to the random Nano-crystallization,

and this can explain the XRD results.

a) b)

c)

d)

Fig.5.9: SEM pictures; cross section of a silicon bar with

a Ti-W-N layer

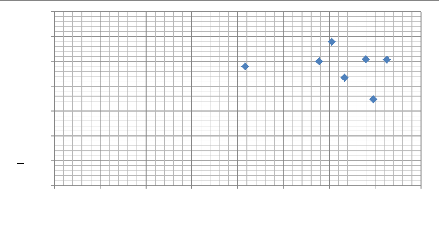

5.4. Interpretation of nanoindentation

results

The charge-discharge curves of different bars for different

depths and effort are given in the

annex, the mechanical properties obtained for each test are

given in the following curves, besides the tables of the results are given in

the Annex II.

Chapter 5: Analysis of the results

Modulus of elasticity E (G Pa )

140

120

100

40

80

60

20

0

0 50 100 150 200 250 300 350 400

Max depth (nm)

79

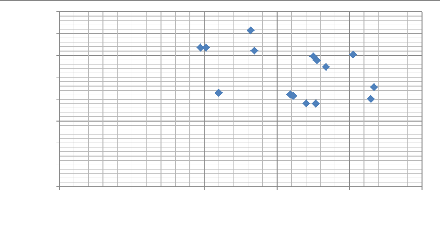

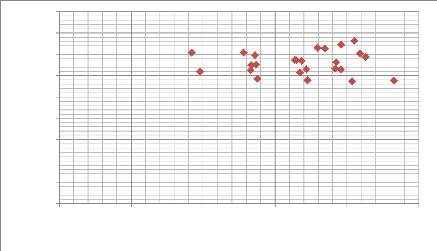

Fig.5.10: Scatter plot of modulus of elasticity as a

function of the max depth (nm)

Hardness (GPa)

3000

2500

2000

1500

1000

500

0

0 50 100 150 200 250 300 350 400

max depth (nm)

Fig.5.11: Scatter plot of hardness as a function of the max

depth (nm)

Chapter 5: Analysis of the results

Modulus of elasticity E (G Pa)

4000

8000

7000

6000

5000

3000

2000

1000

0

0 50 100 150 200 250

max depth (nm)

80

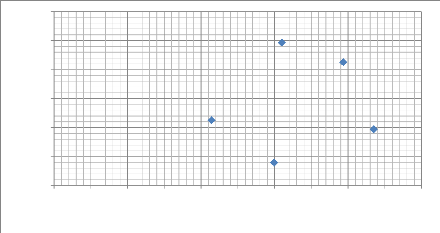

Fig.5.12: Scatter plot of modulus of elasticity as a

function of the max depth (nm)

Hardness H (MPa)

350

300

250

200

150

100

50

0

0 50 100 150 200 250

max depth (nm)

Fig.5.13 Scatter plot of hardness as a function of the max

depth (nm)

Chapter 5: Analysis of the results

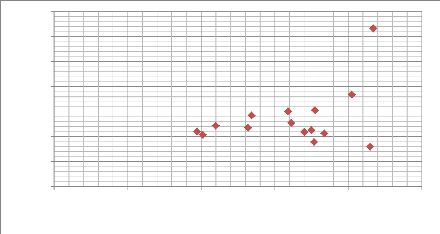

Modulus of elasticity E (GPa)

300

250

200

150

100

50

0

0 50 100 150 200 250

max depth (nm)

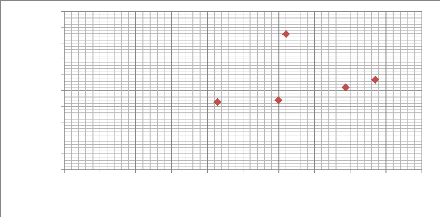

81

Fig.5.14 scatter plot of modulus of elasticity as a

function of the max depth (nm)

Hardness H ( M Pa)

4000

9000

8000

7000

6000

5000

3000

2000

1000

0

0 50 100 150 200 250

max depth (nm)

Fig.5.15 scatter plot of hardness as a function of the max

depth (nm)

There are in fact four factors to optimize in order to

increase the hardness of a layer: the nature of the material of deposition; its

microstructure and its architect which are more or less interdependent, and

also there is the ionic bombardment during the growth of the film.

If we make a comparison between The hardness values obtained

and the hardness values of layers with titanium, we find that our values are of

low hardness, this can be explained by the low content of interstitial element

(nitrogen) which is 5%, what means a large percentage of

82

Chapter 5: Analysis of the results

substitutional elements (the transition elements of titanium

and tungsten). Indeed, when the content of transition elements increase, the

average size of the crystallites decreases [TAK08/A], the decrease in the size

of the crystallites is the origin of the decrease in the hardness. This effect

is found in the Hall and Petch law, which reflects the fact that the tensile

stress of material is inversely proportional to the square root of the mean

crystallite size [TAK08/A].

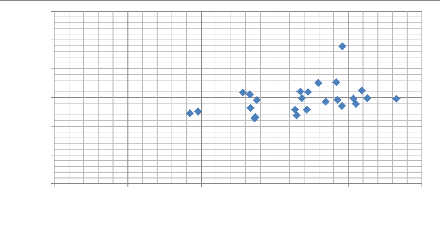

Modulus of elasticity E (G Pa )

170

165

160

155

150

145

140

0 20 40 60 80 100 120 140 160 180 200

max depth (nm)

Fig.5.16: Scatter plot of modulus of elasticity as a

function of the max depth (nm)

Hardness H (MPa)

20000

18000

16000

14000

12000

10000

4000

8000

6000

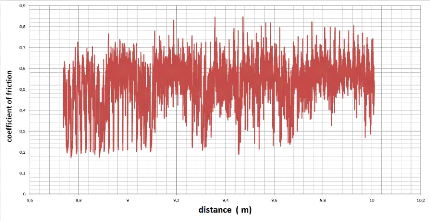

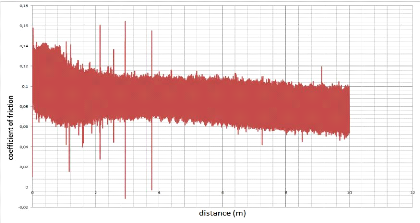

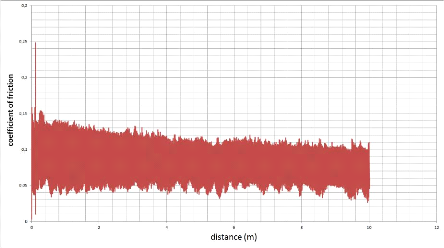

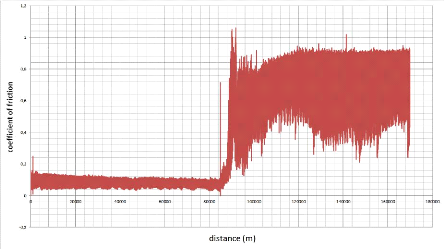

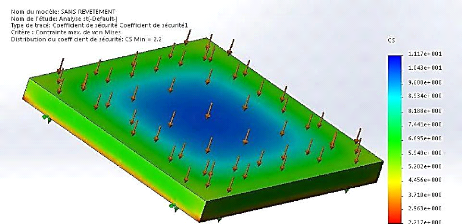

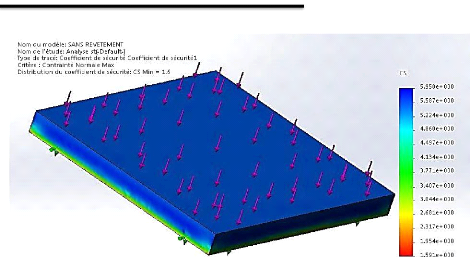

2000