1.2.3. Corrosive wear

Corrosive wear is the friction removal of the reaction product

formed on the surfaces by chemical attack. Among these, we can site:

- Hydrochloric (HCl) and hydrobromic (HBr) acids, which

originate from the combustion of ethylene halides contained in the anti-knock

additive of leaded gasolines;

- Sulfuric acid (H2SO4), which comes from the cold

condensation of sulfuric anhydride (SO3) with the fuel combustion water in

engines operating with sulfur fuel, which is particularly the case for diesel

fuels.

- The organic acids coming from the partial oxidation of the

oil or the fuel, the shortest in length of organic chain are the most

corrosive. Corrosion is of particular concern when water and acids can condense

on metal surfaces, i.e. when the temperature of these walls is relatively low,

for corrosion to occur several conditions must be met:

- A corrodible metal (steel or antifriction alloy);

- A corrosive medium (aqueous electrolyte with a pH

sufficiently low to corrode the steel); - An intimate contact.

The corrosion can be eliminated by one of the following

methods:

- Elimination of sensitive metal (choice of a non-corrodible

alloy or an organic material);

- Placing a barrier between the metal and the medium;

In general, the first means of action is only rarely economically

or technically acceptable in the case

of internal combustion engines.

The second mean of action is specific to anti-rust and

anti-corrosion additives.

But the most useful way of protection is the coating (for more

information see the literature

review).

1.2.4. Fatigue wear

1.2.4.1. Fatigue fracture mechanism

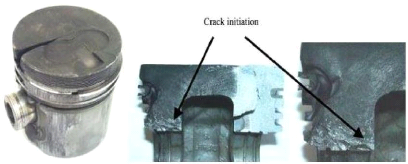

By mechanical fatigue it is meant that the piston is subjected

to external variable loading. The resulting stress causes cracks to nucleate

and propagate in critical stressed areas. As shown in Fig 1.12, there are

mainly two stress critical areas where crack initiates: piston pin holes and

those regions on both sides of the bowl rim areas which are located on the same

vertical plane that contains the pin holes. It is also observed that there is

only one visible crack for mechanical fatigue.

Fig.1.12: Gasoline engine piston with a crack from one side

of the pin hole to the head

14

Chapter 1: Overview on engine's piston

Under thermal fatigue, thermal gradients develop stress in two

ways. Thermal stresses due to the distribution of the temperature along the

vertical axis of piston - high temperatures at the top and lower temperatures

at the bottom - and that due to the different temperatures on the piston head

due to the flow of the hot air or fuel impingement. In the first case several

fatigue radial cracks over the whole piston head can be observed.

The cracks so formed gradually grow under the fatigue

conditions until it develops into a fracture on the crown. If severe enough,

fracture continues across the crown surface to have the piston sliced to

parts.

1.2.4.2. Fatigue damages to piston

Apart from piston crown, fatigue cracks are developed in other

parts of piston as well and it includes piston rings and piston skirt.

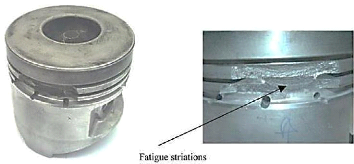

- Piston ring

As the wear on cylinder walls increases, clearance between the

piston and cylinder wall becomes high. Eventually, pressure acting on the ring

increases (because the ring comes out of the groove) and consequently stress

increase on the groove. The stresses at those fillet portions in the ring

groove seem to be sufficient to initiate fatigue cracks on the piston.

Fig .1.13: Engine piston with damaged grooves

In case the rings are not fitted correctly in the grooves, the

resulting misalignment stresses the ring material by the continuous

reciprocating motion. This will accelerates the fatigue crack propagation which

in turn stresses the ring lands and cause material to fracture away from the

ring land areas, as depicted in Figure 1.13.

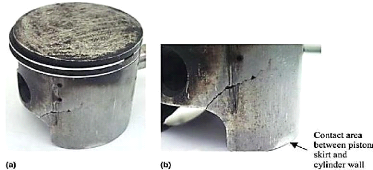

- Skirt fracture

If the clearance between piston and cylinder becomes too

large, piston will be misaligned with cylinder, i.e., piston will be always at

an angle with the cylinder walls. This causes the piston to flutter within the

bore during the engine running. With larger clearances, the piston rotation

angle also increases and makes contact with cylinder walls at two points; the

bottom part of the skirt and the top part of the piston head. These contacts

introduce a flexural load on the piston skirt. The

15

Chapter 1: Overview on engine's piston

consequence will be the formation of stress concentration

areas where cracks initiate and propagate onto fracture, as shown in Figure

1.14.

Fig .1.14: Initiation and propagation of cracks onto

fracture

1.3. Piston-cylinder Lubrication

1.3.1. The lubrication regimes in the piston-cylinder

couple

Based on studies made by several researchers, it can be confirmed

that:

- The main piston-cylinder lubrication regime is the hydrodynamic

regime;

-boundary Lubrication and sometimes dry contact occur in the PMB

and PMH areas, according to:

1. Courtney, Pratt, Tudor [PAN85] Using the measurement of

the contact resistance of the segments-cylinder;

2. Wing and Sauders [PAN85] from the study of the rapid

variations of the oil film thickness by adopting an indirect measurement of the

piston-cylinder diametral clearances;

3. Furuhama in 1959 [FUR59] after he noticed the

insufficiency of the hydrostatic lubrication which cannot explain a limit

lubrication of the segments with the TDC which possess in this position a zero

speed and consequently a zero film thickness;

4. Brown and Hamilton in 1975 [BRO76] by measuring the

pressure distribution in the oil film and the thickness of the film in the

vicinity of the TDC by capacitive proximity sensors. They demonstrated the

limiting lubrication of the segments in the vicinity of TDC and BDC

5. Allen and al in 1978 [ALL84] From the measured values of

the thickness of the oil film in the vicinity of the TDC, less than 0.25

ìm, they assert the existence of a metal / metal contact in these

zones.

6. Richez and al [RIC82] carry out tests on an engine and

show that the friction increases with temperature or with the decrease in

viscosity. The measurement of the amplitudes of the roughnesses (2 to 4

ìm) and the thicknesses of the oil film (0.5 to 10 ìm) enabled

them to demonstrate the existence of a metal / metal contact zone in the

vicinity of the TDC.

16

Chapter 1: Overview on engine's piston

7. Uras and Patterson [URA87] Measuring the friction force of

the piston and the measured friction force decreases as the piston velocity

increases. This frictional force also becomes important in the vicinity of the

TDC and BDC, indicating that the friction becomes limited in these regions.

8. Myers and al in 1990 [MYE90] Install capacitive gauges and

surface thermocouples to study the influence of different parameters on the oil

film in the vicinity of the TDC. They study the friction at engine start-up and

thus notice the breakage of the oil film which causes the metal / metal

contact.

- The boundary lubrication is located in the expansion and

compression cycles:

1. Rogowski in 1961 [ROG61] after measuring the

piston-cylinder friction force by means of a special device. He noticed that

this force becomes important during the compression and relaxation phase;

2. Furuhama and al in 1978 [FUR59] with the improvement of

their experimental set-up enabled them to show that the measured frictional

forces are very high in the second half of the compression phase and the first

half of the expansion phase at the TDC. The considerable increase in the

friction force confirmed the existence of a metal / metal contact between the

segment and the cylinder in these zones.

1.3.2. The main lubrication regime formulations in the

piston-cylinder couple 1.3.2.1. Formulation of Furuhama and

al

Experiments by Furuhama [RAY74] on driven engines and in

normal operation led him to state that the main mode of lubrication of the

piston and cylinder is of the hydrodynamic type. The Reynolds equation under

these conditions is written:

???? (h3

?? ?? · ????

????) = 6 · ???? · ??h ???? + 12 ??h

????

with h: oil film thickness, ?? :

Dynamic viscosity of lubricant, ??: Average hydrodynamic pressure, ????:

Speed of the piston.

The resolution of this equation makes it possible to determine

the pressure and velocity

distributions in the oil film.

1.3.2.2. Formulation of Richez and

al

Richez and al [RIC82] Introduce mixed lubrication of the segments

and take account of the surface

roughness. By noting that the heights of surface's roughness of

the segments and of the cylinder are

of the order of 2 to 4 ìm and that the thickness h of the

oil film is of the order of 0.5 to 10 ìm, they

define a factor ë= h /??, and proposed the criterion:

?? = 1 The lubrication is mixed;

?? = 1 The lubrication is hydrodynamic.

They also give the law of distribution of pressure and speed in

the oil film:

?? h3 ???? + ??h

???? (???? 12 ?? · ????

????) = ???2 ? · ??h ????

17

Chapter 1: Overview on engine's piston

???? = 1 - 0.9 exp (- 0.56 h

?? )

1.3.3. Generality on anti-wear additives (AW) in boundary

regime 1.3.3.1. Boundary regime and tribofilm

Lubricating oil consists of one or more base oil which

represents the framework of the product. However, for certain applications, and

particularly at high temperatures and pressure (as in the case of pistons), the

base oil is no longer efficient. In order to meet the various uses, multiple

and different additives are added, specific to each use. Among the main types

of additives are anticorrosive, anti-oxidation and anti-wear (AW) dispersant

additives. These additives influence the behaviour of the lubricant by

reinforcing its properties or by adding it others of which it is devoid;

Researchers in the field of lubrication develop different

laboratory tests and each test fulfils a given function. These tests are

Interesting on the mode of application or the behaviour of the lubricant. The

formulation of lubricants requires control of the functioning of each additive

(its reactivity to the metal surface and its mode of action) and their impact

on the environment [TAN07].

In order to improve the performance of the lubricants in

boundary regime in order to avoid seizure and to have reasonable friction,

additives and in particular anti-wear additives (AW) and extreme pressures (EP)

are incorporated in them. These compounds act directly on the metal surface by

forming a protective film on surfaces called tribofilm by chemical reaction or

physical adsorption.

Tribofilms formed in the boundary lubrication regime are

designed to reduce friction and to protect the surface from wear due to

lubricant/surface chemical reactions induced by temperature and pressure

conditions.

Boundary lubrication is a complex phenomenon in which several

parameters intervene such as solid-lubricant interactions, metallurgy,

roughness, corrosion, temperature, pressure and kinetics of chemical

reactions.

In the limit lubricating regime, the height of the surface

roughness becomes greater than the thickness of the film at the interface, the

oxide layer which protects the surface is removed and the two surfaces are

brought into contact. This situation causes wear, increases friction and can

cause welding of the roughness. The viscosity of the oil no longer intervenes

under these extreme conditions, it is the additives present in the oil which

will interact chemically with the metal surfaces to form the tribofilm whose

thickness is a few tens of nm and which protects the Parts against wear

[GEO79].

The additives (AW) by forming their own sacrificial film

replace the oxide protective layer and considerably reduce the wear rate.

1.3.2.2. Types of anti-wear additives

(AW)

The additives (AW) are classified according to their

reactivity with respect to the metallic surface in two types, the active

additives and the non-active ones [PAP98]. The active additives are those which

chemically react with the metal surface to form a film. On the other hand, the

non-active additives form films which are mainly unreacted with the surface.

18

Chapter 1: Overview on engine's piston

Molecules that contain sulfur, phosphorus and halides are

considered active compounds while molecules containing boron, aluminum and

graphite are classified as non-active compounds [DON94].

Table 3.1 shows the main anti-wear additives (AW) used in

lubrication.

|

Additive Families

|

|

sulfuric additives

|

dialkyldithiophosphates of zinc ZnDTP

|

|

2-benzothioyle-tert-nonyle disulfur

|

|

Phenyle sulfur

|

|

Benzyle mercaptan

|

|

Octadecyle mercaptan

|

|

Dodecylebenzylemercaptan

|

|

Ditert-octylemercaptan

|

|

Phosphoric

additives

|

Alkyl d'acide phosphoré

|

|

Alkyl phosphoré

|

|

Phosphites

|

|

Borate

Additifs

|

Esters boratés

|

|

Borates de potassium

|

|

Borates de calcium

|

|

mixed Additifs

|

Dithiophosphates métalliques (Zn,Co,Ni,..)

|

Table 3.1.The main anti-wear additives (AW) used in

lubrication

The universally used additives (AW) are

dialkyldithiophosphates and zinc (ZnDTP). This success is mainly due to its

good antioxidant and anti-wear properties and its low cost [TAN07].

Several authors have shown that the chemical structure of

sulfur-containing additives affects tribological performance, for example.

Disulfides have been shown to perform better in anti-wear AW than monosulfides

due to weak S-S bond in disulfides which is Easier to break than the C-S bond

in monosulfides [FOR70].

Croszek [GRO71] Considers that the anti-wear (AW) activity of

the disulfides depends on the electronegativity between the chemical elements

of this molecule.

19

Chapter 1: Overview on engine's piston

Sakuraia Has shown that oxygen in oil plays an important role

in the formation of oxide films and appears to have a good influence on

tribological behavior [FEN61]. From the chemical reactivity of some additives,

he concluded that oxygen and oxide films prevent wear on surfaces and reduce

friction.

Wheeler [WHE78] differentiates two types of wear: soft wear

and severe wear. Under severe pressure and temperature conditions, a

significant amount of iron sulfide is detected in the wear traces in comparison

with the mild pressure and temperature conditions, and concluded that under the

effect of the elevation of Temperature and pressure, the sulfur compounds react

by chemical corrosion with the metal surface to form iron sulfide.

Temperature affects the tribological behavior of sulfur

additives and the formation of tribofilms. Temperature seems to have a limited

effect on the decomposition of sulfur additives by promoting the formation of

iron sulfide films which improves tribological performance [TAN07].

Chapter 2

Aluminum and its alloys

22

Chapter 2: Aluminum and its alloys

2.1. Properties of non-alloyed aluminum (1000

series)

There are many grades of unalloyed aluminum, known

commercially as pure aluminum. These standard grades are part of the 1000

series of AFNOR standards. The purity of aluminum is always greater than 99.00%

(grades 1100 and 1200), very often higher than 99.40% (grade 1040), but can

reach 99.80% (grade 1080) or even 99.90% (grade 1090).

It is also possible to obtain a high purity aluminum of 99.95

% (grade 1095), 99.98 % (grade 1098), 99.99 % (grade 1199), and even an

aluminum of very high purity (greater than 99.996%, or even equal to

99.999%).

The structure of the pure aluminum is face-centered cubic at

any temperature below its melting point (660 °C). The main physicochemical

properties of unalloyed aluminum are given in Table 2.1: (At 20 °C for a

pure aluminum of 99.996%):

|

Melting temperature G??

|

660°C

|

|

Crystal structure

|

CFC

|

|

Density ??

|

2700 Kg/??3

|

|

Thermal conductivity ??

|

237 ????-1k-1

|

|

Coefficient of linear expansion ??

|

23.1x 10-6 k-1

|

|

Electrical resistivity ????

|

0.0265 ??????

|

Table 2.1: Physicochemical properties of unalloyed

aluminum

These properties are the reason why the unalloyed aluminum is

widely used (in developed countries more than 40% of the aluminum consumption

takes place in this state).

Table 2.2 gives the main mechanical properties of unalloyed

aluminum:

|

Ultimate tensile strength ????

|

40 à 50 MPa

|

|

Yield strength Re

|

10 à 20 MPa

|

|

Proof stress Re0.2

|

20 à 35 MPa

|

|

Young's Modulus E

|

63 à 71 GPa

|

|

Elongation to rupture A%

|

50 à 70%

|

|

Poisson's ratio õ

|

0.33 à 0.35

|

Table 2.2: Mechanical properties of unalloyed

aluminum

2.2. Aluminum alloys

The main alloying elements introduced into aluminum are

copper, manganese, magnesium, silicon, zinc and lithium. These elements can be

added individually or in combination. On the opposite, certain other elements

are more or less excluded, in order to improve a particular property. For

example the tenacity of alloys with magnesium and silicon is greatly improved

by additions of manganese and chromium with limited contents (often Cr <0.4%

and Mn <1%) and by a severe limitation of the contents of harmful elements

such as iron.

23

Chapter 2: Aluminum and its alloys

2.2.1. Classes of aluminum alloys

The aluminum alloys are classified according to the main alloying

element (s). We can

distinguish:

- Aluminum/copper alloys of the 2000 series;

- Aluminum/manganese alloys of the 3000 series;

- Aluminum/silicon alloys of the 4000 series;

- Aluminum/magnesium alloys of the 5000 series;

- Aluminum /magnesium/silicon alloys of the 6000 series;

- Aluminum/zinc alloys of the 7000 series;

- Aluminum alloys and other elements of the 8000 series.

We can also distinguish:

- Peening alloys (not hardening by heat treatment): which are

aluminum/manganese alloys and

aluminum/magnesium alloys;

- Heat treatment hardening alloys: which are aluminum/copper

alloys, aluminum/magnesium

alloys, aluminum/silicon alloys and aluminum/zinc alloys.

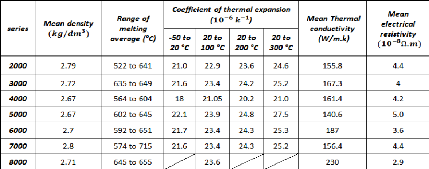

2.2.2. Physical properties of aluminum alloys

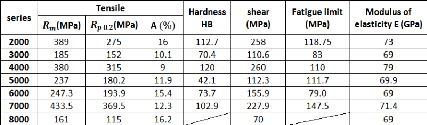

Table 2.3 gives the main physical properties of the different

series of aluminum alloys (the mean value of different experimental results are

considered):

Table 2.3: Physical properties of the different series of

aluminum alloys

2.2.3. Mechanical properties of aluminum

alloys

It is well accepted that the properties of aluminum alloys are

determined essentially by the microstructure of the alloys obtained.

The microstructure is essentially conditioned by the nature,

the quantity and especially the distribution of the elements of addition. Most

metallic elements can be alloyed with aluminum, but only a limited number of

those elements are used as the main addition and condition the properties of

the alloys.

24

Chapter 2: Aluminum and its alloys

Table 2.4 below represents the mean values of the mechanical

properties for different series of aluminum:

Table 2.4: Principal mechanical properties of different

series of aluminum

2.2.3.1. Static strength

Table 2.4 gives the mechanical strength obtained for each of

the series of aluminum alloys. In fact, those characteristics can be varied

depending on many factors.

2.2.3.2. Tenacity

Three categories of aluminum alloy can be considered on the

tenacity point of view:

- Tenacity of low- and medium-strength alloys: those alloys are

of 1000, 3000, 5000 series and

all of other series in the annealed state;

- Tenacity of alloys of the 6000 series: Al-Si-Mg alloys with

medium resistance of the 6000 series

are commonly used for working structures;

- Tenacity of high strength alloys: those alloys are of 2000 and

7000 series.

For the high strength alloys, it can be noted that:

- The tenacity increases when the yield point decreases.

- The newest alloys currently used for the construction of modern

structures of aircraft are

designed to offer a particularly high tenacity:

? The 7475 is the aluminum alloy which has the best tenacity;

? The alloys 7010, 7050, and 7150 offer the best compromise

between strength and

tenacity.

2.2.3.3. Endurance strength

The Wohler curves of aluminum alloys have the following

characteristics:

- There is no asymptote up to 108 cycles, so the

fatigue test must be kept running up to 108 cycles to determine the

fatigue limit;

- The ratio between the fatigue limit at 108 cycles

(in alternating stresses) and the tensile breaking limit is equal to:

- 0.35 to 0.45 for Peening alloys (1000, 3000 and 5000 series

alloys);

- 0.25 to 0.35 for heat treatment hardening alloys (2000, 6000

and 7000 series alloys); In general, this ratio decreases when the breaking

load increases. Different parameters can influence the rate of fatigue

cracking:

25

Chapter 2: Aluminum and its alloys

in

- The stress ratio R = Sm : the rate

of fatigue cracking increases when R increases;

- The medium: humid or salty aggressive medium

accelerates fatigue cracking;

- Overloads: during a fatigue test, if the stress

intensity factor is temporarily increased by a tensile overload, a significant

reduction in the rate of cracking is observed after suppression of the

overload.

2.2.3.4. Corrosion resistance

In practice, aluminum has an excellent corrosion

resistance, because of that it can often be used without coating. Adequately

chosen, aluminum alloys without coating can resist to freshwater, sea water,

and so many chemical products.

However, like the most common metals, corrosion damage

can occur in different forms, depending on the class of the aluminum alloy, its

metallurgical state, the exposure conditions, assembly and stressing

conditions.

The principal forms of corrosion that can be

encountered on aluminum alloys are:

- General corrosion or uniform

corrosion

The exposed aluminum instantly covers with an oxide

layer of 5 to 10 nm thick, and its corrosion resistance depends on the

stability of this oxide layer in the corrosive medium. General corrosion is

characterized by the uniform decrease of thickness over the entire metal

surface; the oxide layer is dissolved in a regular manner by the corrosive

agent.

In a natural, rural or marine atmosphere, the

corrosion rate of aluminum is extremely low, even insignificant, and does not

exceed 5 pm / year. In general, the general corrosion resistance of aluminum

depends on the pH of the corrosive medium, that corrosion cannot practically

occur in an acidic medium with pH <4 and in a basic medium with pH>

9.

In the most aggressive mediums such as marine mediums,

copper-containing alloys (2000 and 7000 series) require protection; On the

other hand, the alloys of the 3000, 5000 and 6000 series may have a corrosion

resistance at least equal to that of the non-alloyed aluminum.

- Pitting corrosion

Pitting corrosion is a much localized form of

corrosion, which appears by the formation of cavities or recesses on the

surface, in which the diameter and depth depend on the class of the alloy, the

corrosive medium and the exposure time.

The rate of deepening of the pits generally decreases

due to the formation of hydrated alumina which hinders considerably the

exchanges between the corrosive medium and the metal. Experiments show that the

rate of propagation of pits v is related to time t by a

relation of the type:

V= k

· t1/

3

All the aluminum alloys are sensitive to pitting

corrosion, the best results being obtained with a content of 1% of iron (it is

the case of alloys 8006, 8011 for example), likewise the presence of 0.1 to 0.2

% of copper improves the resistance for the penetration of pits (the case of

alloy 3003).

26

Chapter 2: Aluminum and its alloys

- Galvanic corrosion

When two different metals are in electrical contact in a

corrosive medium, they form a cell which produces current by consuming the most

electronegative metal which constitutes the anode. Aluminum is the most anodic

material compared to other metals (except zinc and magnesium). Aluminum will

therefore often be the victim of mixed assemblies.

In fact, the attack rate of aluminum depends on: the

difference of potential between the two metals present; on the electrical

resistance between the two metals and on the corrosive medium and more

particularly on its conductivity.

- Corrosion cracking or Intergranular corrosion

The intergranular corrosion encountered in various metals and

aluminum alloys is the corrosion that propagates in the metal by consuming only

the grain boundaries. This type of corrosion is due to the presence at the

grain boundaries of a continuous and anodic zone compared to the interior of

the grains.

For aluminum alloys, it mentioned that:

- Alloys of 1000, 3000, 4000 and 6000 series: are not sensitive

to intergranular corrosion;

- Alloys of the 5000 series: Al-Mg alloys with less than 3.5%

Mg are normally not susceptible to intergranular corrosion and Al-Mg alloys

with more than 3.5% Mg may be sensitive to intergranular corrosion especially

if the magnesium content is high;

- Alloys of the 2000 and 7000 series: have a good resistance

to the intergranular corrosion obtained by a quick quenching.

2.2.4. Standards defining aluminum alloys 2.2.4.1.

Wrought aluminum alloys

This family of aluminum alloys is the most widely used in

industry. It includes all commonly

rolled products.

The NF EN 573 standard defines two European systems for the

designation of these aluminum

alloys: the numerical system and the alphanumeric system.

The numerical system uses a 4-digit code which refers indirectly

to the chemical composition.

According to this system the designation of an alloy includes

successively:

4 letters: EN AW

EN refers to European standards;

A indicates that it is aluminum;

W specifies that it is wrought metal.

4 digits:

The first digit indicates the series of alloys

The second digit can be:

- 0 if it is the original metal,

- 1 to 9 if the alloy has certain particularity (purity of a

unalloyed aluminum, variant of an alloy,

etc.);

27

Chapter 2: Aluminum and its alloys

The third and fourth digits have different meanings depending on

whether they are:

- Of unalloyed aluminum; they are then the first two decimal of

the number expressing the

minimum Al content,

- Of an alloy: these two numbers serve only to differentiate the

grades of the same group.

Examples:

EN AW-1098 = aluminum with at least 99.98% purity;

EN AW-4015 = alloy wit 1.8% of Si and 0.9% of Mn;

In the alphanumeric system, unalloyed aluminum and aluminum

alloys are distinguished. For

the unalloyed aluminum, the designation begins with the chemical

symbol of aluminum Al

followed by the minimum content of the metal in % expressed in

one or two decimal.

Example: EN AW-Al 99.98 = Aluminum with at least 99.98%.

Normally this designation should be preceded by a numerical

designation and the minimum

content of the metal in % placed in brackets, the precedent

example is designed as EN AW-1098

[A 99-98].

For aluminum alloys, the designation begins with the chemical

symbol of aluminum Al,

followed by the chemical symbol (s) of the main alloying element

(s), each followed by a number

representing the average content in % of the indicated

element.

Examples:

Al Si2Mn = alloy of 1.8% of Si and 0.9% of Mn;

Al Si10 = alloy of 10% of Si.

Normally, this designation should be preceded by the numerical

designation and be placed in

brackets such as the following:

EN AW-4015 [AlSi2Mn];

EN AW-4045 [AlSil0];

2.2.4.2. Cast alloys

Most of these alloys are easy to mold (permanent mold or sand

casting). Many of these alloys contain sufficient silicon to cause a eutectic

reaction, which gives the alloys a low melting point, good fluidity and good

molding. The cooling in the die casting is faster than sand casting, which

results a grain refinement and improved mechanical properties. Grain refinement

is also caused by boron and titanium additives.

Designation according to the standard NF EN 1780, is given as:

prefix EN; space ; Letter A (for aluminum); Letter B (for remelting ingots) or

C (castings piece) or M (mother alloys); A dash ; followed by five digits

representing the position of the chemical symbols giving the composition of the

alloy ordered by decreasing content and limited to 4 elements.

Example:

EN AB-45400 [Al Si5Cu3] or EN AB-Al Si5Cu3; remelting ingots

in aluminum alloy with 5% silicon and 3% copper.

28

Chapter 2: Aluminum and its alloys

2.3. Aluminum-Silicon Alloys (4000 series)

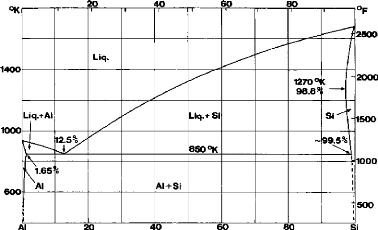

The equilibrium diagram of the Aluminum-Silicon alloy is given in

Figure 2.1.

Fig.2.1: The equilibrium diagram of the Aluminum-Silicon

alloy

The eutectic point varies from 11.7% Si to 14.5% Si. The most

probable value is 12.5% Si. With rapid quenching the eutectic point can rise to

17% Si.

The main physical and mechanical properties of

aluminum-silicon alloys have been given in Tables 2.3 and 2.4.

Hardness increases with increase in silicon content almost

linearly and reach values between 500 and 700 MPa for 15% Si and 1000 MPa for

60% Si.

The modulus of elasticity has an average value between 85 and

95 GPa, this value increasing with temperature. The impact resistance also

increases with increasing temperature.

The endurance strength is relatively low; it varies from 50 to

70 MPa for the hypoeutectic alloys and from 70 to 80 MPa for the hypereutectic

alloys. The addition of cobalt and manganese increases the endurance strength.

This strength abruptly decreases with the temperature increasing until 327

° C.

The compression strength is 10 to 15% greater than the tensile

strength.

The wear resistance is very good, especially for hypereutectic

alloys. For alloys of 20 to 25% Si, the wear resistance is 10 times more than

that of the non-heat treated steel.

The presence of calcium and sodium in the alloys increases

their porosity. To reduce it, rare earths are added. Vacuum coatings are also

used.

The silicon is an inert element in most corrosive mediums, the

corrosion resistance of the aluminum-silicon alloy is the best compared to

other aluminum alloys.

The coefficient of thermal expansion is relatively low

compared to other aluminum alloys; it is decreased with the increase in silicon

content.

29

Chapter 2: Aluminum and its alloys

According to Table 2.5 it is noted that the coefficient of

thermal conductivity is decreased with the increase of the Silicon content.

|

Silicon content (%)

|

Temperature (K)

|

|

300 à 400

|

300 à 600

|

|

5

|

22.1 à 22.5

|

24.1 à 24.5

|

|

7 à 9

|

21.4 à 21.7

|

23.1 à 23.5

|

|

12

|

19.9 à 20.6

|

21.6 à 23.1

|

|

> 14

|

18 à 19

|

20 à 21

|

Table 2.5: Coefficient of the thermal conductivity

(10-6 K-1)

The alloy density is decreased with the increasing in Silicon

content. An alloy of 6 to 9% Si has a density of 2650 to 2700 ????/

??3 and with 10 to 13% Si has a density of 2600 to

2650????/??3.

Chapter 3

Vapor deposition and thin layer

characterization techniques

31

Chapter 3: Vapor deposition and thin layer

characterization techniques

3.1. Physical bases of the vacuum technique 3.1.1.

Vacuum and gaseous phase of the materials

Materials in the gaseous state are characterized by a

great mobility of their molecules. Because of this; they always occupy the

volume of the container in which they are enclosed. In physics and technology,

we call vacuum, the state of a gaseous volume whose pressure is below the

atmospheric pressure. For convenience, vacuum is divided into four ranges: low

vacuum, fine or medium vacuum, high vacuum, and ultrahigh vacuum.

Table 3.1 gives the general characteristics of

vacuum:

|

characteristics

|

Vacuum

|

|

Low vacuum

|

Medium vacuum

|

high vacuum

|

ultrahigh vacuum

|

|

Pressure range (bar)

|

1 à 10-3

|

10-3 à 5 · 10-5

|

·

5 1012 a

|

< 10-12

|

|

Number of molecules in

?? ??????

|

1019 à 1016

|

1016 à 1013

|

1013 à 1010

|

1010

|

|

Mean free path ??

|

A « ??

|

A = ??

|

A > ??

|

A » ??

|

|

Flow regimes

|

Viscous flow

|

intermediate flow

|

molecular Flow

|

Molecular Flow

|

|

Application

|

Packaging,

drying

|

CVD, plasma

|

PVD

|

Ion beams

|

Table 3.1 General characteristics of

vacuum

According to kinetic theory, the molecules of a gas

move in a continuous and chaotic manner. They collide and between their impacts

their movement is rectilinear. The distance between two successive impacts is

called the free path of the gas molecule. After each impact, the magnitude and

direction of the velocities of the molecules change.

When the gas occupies a limited volume, there are

molecular impacts on the walls of the container. So the gas pressure is the

result of the statistical mean of these impacts.

A general criterion characterizing the vacuum in a

system is the ratio of the mean free path ë of the molecule with a

characteristic dimension ?? of the vacuum chamber, that is to

say:

A

Kn = (3.1)

??

The Kn ratio is known as Knusden

number, when Kn » 1, i.e. X » l the

flow regime of the gas is molecular flow. When Kn « 1,

i.e. X « l the regime is called viscous flow.

The limiting temperature above which the gas cannot be

condensed, whatever the pressure, is called the critical temperature. This is a

fundamental criterion for distinguishing gases from vapors.

Chapter 3: Vapor deposition and thin layer

characterization techniques

Materials are in the gaseous state if the temperature

is above their critical temperature. If the temperature is below their critical

temperature, they are in the vapor state.

The pressure can be written in the form of the following

equations:

P= ??

· k

· T (3.2)

?? : The number density of the molecules

(m-3);

k : The Boltzmann constant (k 1.38

· 10-16 N

· m/K); T

: The gas temperature.

1

P = 3 ??v2 (3.3)

?? : The density of the gas (kg

· m-3);

vv2 : The-root-mean-square speed of

molecules.

When the gas system is a mixture of different gases,

each gas exerts its pressure Pi independently of the

others. The total pressure PE is then the sum of the

partial pressures (Dalton's law):

i=??

PE = ?Pi (3.4)

i=1

According to the kinetic theory, the mean kinetic

energy of the translation of molecules is proportional to the thermodynamic

temperature of the gas:

|

m

· v2

|

3

2

· k

· T (3.5)

|

|

2

|

|