1.2.1. Adhesive wear

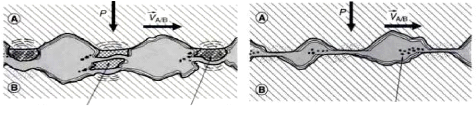

Adhesive wear or wear by metal - metal contact is the most

basic form of deterioration of surfaces. It is due to shear failure, during

friction, micro-welds or junctions formed instantaneously between the opposing

asperities of the two surfaces, in dry friction mode or in limited or mixed

lubrication. The formation of these welds, which is very localized, is favoured

by the thermal energy dissipated by friction, associated with very high contact

pressure.

According to its nature, the weld will be a true weld or "hot

weld", or a simple physical bond or "cold junction", therefore, depending on

the shear strength of the junction, shear breakage occurs inside the softest

metal or, on the contrary, at the junction.

The deterioration thus takes all forms ranging from severe

scratching to light scratching or soft adhesive wear (Figure 1.8.).

In the first case, the deterioration, in its most serious form

which is the seizure of the surface (Figure 1.7.), is characterized by metal

stripping, transfer of metal from the softest surface to the hardest surface,

(Burning) and the emission of relatively large dimensions (some ìm to

some hundred ìm) of metal wear particles.

Fig .1.7: Piston seizure

11

Chapter 1: Overview on engine's piston

In the second case, the wear rate is very low and the wear

particles consist of very small fragments of metallic oxides of generally

lamellar shape (a typical dimension of the order of one to a few hundredths of

a im).

A The shear strength of the welds TS is

B The shear strength of the junctions

greater than the shear strength of the TS is less than the shear

strength of the

softest metal TB softest metal TB

Wear particules Transferred fragments

Wear particules

|

The shear occurs inside the softest body B, an adhesive

transfer and severe wear.

? Large wear particles, a few im diameters

? Important friction called "internal" or by

welding

|

The shearing occurs at the junctions wear is moderate (soft

adhesive wear)

? Very small wear particles (oxides) about 10 nm diameters

? Low friction known as "external" or by shear

|

Fig.1.8: Mechanisms of adhesive wear: A) severe adhesive

wear - B) soft adhesive wear

In engines, adhesive wear mainly affects the components that come

into contact with each other, such as cylinder and cylinder piston.

The introduction of antifriction additives which act chemically

when the temperature of the contact rises, by attacking the metal in order to

convert it superficially into a self-lubricating, easily shearable film,

generally consisting of metal sulphides and phosphates.

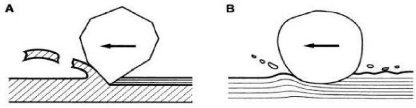

1.2.2. Abrasive wear

Abrasion is a deterioration involving two phenomena

- A material removal from the surface by cutting;

- Plastic deformation of the surface (plowing) without ablation

of material.

Fig. 1.9: Abrasion mechanisms: A) abrasion by cutting - B)

abrasion by plastic deformation

Chapter 1: Overview on engine's piston

The abraded surface thus loses metal in the form of micro

chips and is deeply modified by plastic deformation.

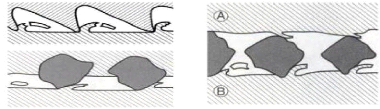

There are two types of abrasion:

- The two bodies abrasion caused by hard asperities or hard

particles embedded on one of the surfaces and wears the other surface;

Two bodies HVA > HVB

Hard asperities or particles Three bodies

embedded on 1 of the 2 surfaces

and wears the other surface Abrasive grains conveyed

between the

two rubbing surfaces.

Fig.1.10: The types of abrasive wear

12

- The three bodies abrasion generated by free abrasive

particles (3rd bodies) conveyed between the friction surfaces, if the size of

these particles is equal to the thickness of the oil film, the abrasion is said

to be normal, it is manifested by scratches having the appearance of cutting

grooves. On the other hand, if the abrasive particles are very small, the

deterioration, whose size and appearance strongly depend on the angle of

incidence of the particles with respect to the surface, is called abrasive

erosion.

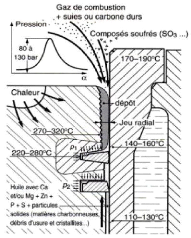

Fig.1.11. Diesel piston head deposit formation

Abrasive wear is countered by hardening of surfaces and

especially by efficient filtration of air (in engines) and oil.

Polishing wear of the cylinders of heavily loaded diesel

engines is a particular form of abrasive wear. The disappearance of the

machining lines by polishing the cylinder bore is due to the combined abrasive

actions of the carbon deposited on the piston crown (2-body abrasion) and the

solid particles carried by the oil (These deposits and sediments contain, in

greater or lesser quantity, microcrystals having a diameter of (0.1 to 0.5

ìm) of mineral salt, some of which are abrasive, resulting from the

interaction of the products of thermal degradation of the organometallic

additives of the oil.

13

Chapter 1: Overview on engine's piston

|