1.1.1.1. Controlled-expansion pistons

Controlled-expansion pistons are pistons with struts that

control thermal expansion. They are installed in gray cast iron crankcases. The

main target of controlled-expansion piston designs, and many inventions in this

field, was and still is to reduce the relatively large differences in thermal

expansion between the gray cast iron crankcase and the aluminium piston

We distinguish in this category the Autothermic pistons,

slotted at the transition from the piston crown to the skirt, at the height of

the oil ring groove. They are characterized by their particularly quiet running

behaviour.

The unalloyed steel struts cast in between the skirt and the

piston pin boss, together with the light alloy that surrounds them, form

control elements. They reduce the thermal expansion of the skirt in the

direction that is critical for the

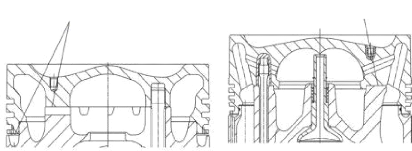

Fig.1.2: BOX-type piston

guiding of the piston in the cylinder.

1.1.1.2. Box-type pistons:

Compared with controlled-expansion pistons, this piston type

is characterized by its reduced mass, optimized support, and box-like, often

slightly oval skirt design. The box-type piston is compatible with both

aluminium and grey cast iron crankcases. With a flexible skirt design, the

difference in thermal expansion between the gray cast iron crank case and the

aluminium piston can be compensated very well in the elastic range. If the box

width is different on the thrust and antithrust sides, the piston is referred

to as an asymmetrical duct piston. Box-type pistons are cast or forged.

1.1.1.3. Forged aluminum pistons:

In engines with very high power densities--such as highly

loaded

turbocharged gasoline engines--cast pistons reach their

limits. Forged pistons are a particularly good fit for this area of

application; Figure 1.15. Their strength advantage in the temperature range of

up to about 250°C improves the load carrying capacity for lateral forces,

and increases the load carrying

8

Chapter 1: Overview on engine's piston

capacity of the pin bore and the fracture toughness. Forged

pistons are therefore especially well suited for high-speed concepts and

turbocharged engines. Because of the high ductility of the forged material,

they also react more tolerantly peak pressures that can arise if an engine is

operated very close to the knock limit. This allows lower ring land widths,

among other things, and therefore lower compression heights. Since the

manufacturing process is very stable, the forged pistons can be designed to the

limit in order to minimize component weight.

|

1.1.2. Pistons for diesel engines 1.1.2.1. Ring

carrier pistons

Ring carrier pistons; have been in use since 1931. The first

and at times even the second piston ring are guided in a ring carrier that is

securely joined to the piston material by metallic bonding.

The ring carrier is made of an austenitic cast iron with a

similar coefficient of thermal expansion to that of the piston material. The

material is particularly resistant to frictional and impact wear. The top ring

groove, which is the most vulnerable, and the piston ring inserted in it are

thereby effectively protected against excessive wear. This is particularly

advantageous at high operating temperatures and pressures, which are

particularly prevalent in diesel engines.

|

|

|

Fig 1.3: Ring carrier piston

|

Fig.1.4: Ring carrier piston with cooling gallery

1.1.2.2. Cooling gallery pistons

The cooling gap inside the piston head is generally used to

optimize heat extraction. The high-speed collision of the engine oil on the

gallery surfaces improves the heat transfer capacity due to the impact caused

by the movement inside the cylinder. The heat flux removed by the cooling

gallery can reach 60% to 70% of the total heat transmitted to the piston by the

combustion gases, thereby effectively reducing the thermal loading of the

piston. When the engine is running, the cooling oil is injected from the oil

jet nozzle into the gallery through the inlet hole, flows in the

circumferential direction and exits the gallery through the exit hole, the

cooling oil does not fill the piston galley, the cooling oil exits the gallery

at high speed under the inertia of the movement

However, the structure of the cooling gallery limits to some

extent the resistance of the piston. With the steady increase in the maximum

pressure inside the diesel engine there is also the prolonged exposure of the

engine oil to higher temperatures in the piston cooling gallery which causes a

degradation of the characteristics of the lubricant which will not only affect

the piston but all engine components and carbon build-up, thereby reducing

cooling efficiency and resulting in overheating.

9

Chapter 1: Overview on engine's piston

|

1.1.2.3. Optimized monobloc steel

pistons:

This piston type is a single-piece forged steel piston that is

greatly weight optimized. With a small compression height (to less than 50% of

the cylinder diameter) and machining above the pin boss spacing (internal), the

piston mass, including the piston pin, almost corresponds to the mass of a

comparable aluminium piston with piston pin. In order to improve the piston

cooling, the outer cooling cavity is closed off by two cover plate halves. The

MONOTHERM® piston is used in passenger car and commercial

vehicle engines with peak cylinder pressures of up to 20 MPa.

1.1.2.4. Composite pistons

|

|

|

Fig.1.5: Optimized monobloc steel

piston

|

The composite piston enables the incorporation of cooling

cavities and the combination of the properties of various materials in one

piston. The performance range of four-stroke engines with composite pistons

extends from 500 to 30,000 kW, with up to 20 cylinders. Areas of application

include genets, main ship drives and auxiliary ship drives, and heavy

construction and railroad vehicles.

Here are many variants of composite pistons. Common to them

all is a design consisting of two main constituents: the piston crown with the

ring belt (upper part of piston) and the piston skirt with the piston pin boss

(piston skirt). The two parts are screwed together with appropriate threaded

fasteners

With two contact surfaces With one contact

surfaces

Fig. 1.6: Upper part of piston cooled by gallery (left) and

by orifice (right)

The upper part of the piston is made of forged steel, while

the piston skirt can be made from three distinct materials:

- Piston skirt made of forged aluminium-base

alloy, forged aluminium skirts, are suitable for low and medium peak

cylinder pressures, exhibit a low mass, and are easy to machine.

- Piston skirt made of nodular cast iron, Key

features of a composite piston with nodular cast iron piston skirt, Figure 1.6,

are low cold piston clearance and the resulting low secondary piston motion as

well as high seizure resistance.

10

Chapter 1: Overview on engine's piston

The casting process, in contrast to forged steel, allows for

undercuts and therefore a lighter design Superior to 200 bar. Compared with

pistons with aluminum skirts, however, the mass is increased as a result of the

higher material density.

- Piston skirt made of forged steel provides

ultrahigh component strength and, related to the process, a material with

extremely few defects. They are suitable for ultrahigh stresses greater than 24

MPa. Similar to pistons with nodular cast iron piston skirts, they provide the

advantage of low cold piston clearance, resulting in low secondary piston

motion.

1.2. Different forms of wear

Metal surfaces which are subjected to solid or fluid friction

in the presence or absence of a lubricant may be affected by wear patterns

which may range from regular, controllable wear (normal wear) to sudden

deterioration causing the failure of the mechanism.

Surface deterioration is an isolated or simultaneous

phenomenon classified into four basic forms: adhesive, abrasive, corrosive and

fatigue.

|