5.2.2 Results

The RSD was 0.78 % within a day and 1.56% within three days,

which complies with the USP 24 requirements (RSD should be less than 2%).

The results of the drug content (Table 5.1) show that the

S&R formulation did not comply with the USP 24 specifications for

paracetamol content (90% - 110% of the labelled amount) after 6 months of

storage under simulated tropical conditions (40°C and 75 % RH).

Table 5.1: The paracetamol content (expressed

as percentage of the labelled amount) before and after 6 months of storage at

40°C and 75 % RH.

Manufacturer

% of the labelled amount per tablet

0 months 6 months

Regal Pharmaceuticals (Cetamol) 95.6

92.5

Smith Kline Beecham (Panadol) 95.0

93.8

S&R Pharmaceuticals (Saramol) 90.8

87.7

II.5.3 In vitro dissolution

5.3.1 Methods

· Preparation of dissolution

medium

68 g of potassium dihydrogen phosphate was diluted to 10.0 L

with distilled water. The pH was adjusted to 5.8 0.05 using a 0.2 N solution

of sodium hydroxide.

· Calibration curve

Stock solution

200 mg of accurately weighed paracetamol was dissolved in

mobile phase to obtain 100.0 ml. 10 ml from this solution were diluted to 100.0

ml. The resulting solution had a concentration of 200 mg/l. 20 ml of this

solution was diluted to 100.0 ml to give a stock solution with a concentration

of 40 mg/l.

Standard solutions

1, 2, 5, 8 and 10 ml of the stock solution were separately

diluted to 10.0 ml using the dissolution medium to obtain standard solutions

having concentrations of 4, 8, 20, 32 and 40 mg/l, respectively.

A calibration curve (absorbance vs. concentration) y = 0.0633x

+ 0.0294 with a correlation coefficient (R2) of 0.9999 was

constructed.

· Dissolution testing

Dissolution profiles were determined using the USP paddle

method (Method 2). Each of 6 tablets was placed inside a dissolution vessel

filled with 900 ml of dissolution medium maintained at 37 0.5°C and

rotated at a speed of 50 rpm.

At different time intervals (5, 10, 15, 20, 25 and 30 min) 5 ml

filtered samples were manually withdrawn, diluted with dissolution medium

(1:40) and spectrophotometrically analyzed at 243 nm. From the absorbance of

each sample, the drug concentration was calculated by means of the calibration

curve.

5.3.2 Results

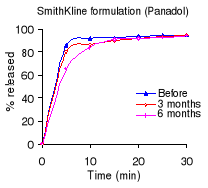

Table 5.2 shows the percentage dissolved within 30 minutes of

dissolution testing and Figure 5.1 the different dissolution profiles. Before

stability testing all drugs complied with the USP 24 dissolution requirements

(not less than 80% of the labelled amount should dissolve within 30 minutes).

The amount of drug released after 10 minutes of dissolution test was more than

80% for the Cetamol and Panadol formulations. The Saramol formulation

disintegrated into larger particles compared to the others two formulations.

The accelerated stability testing did not affect the Cetamol and Panadol drug

percentage released. The amount of drug released from Saramol formulation

decreased, however it remained within USP 24 tolerance limits for dissolution

testing.

Table 5.2: Percentage of paracetamol dissolved within 30

minutes of dissolution testing before and after 3 and 6 months of storage at

40°C and 75% RH. USP requirements: more than 80 % released within 60

minutes.

Manufacturer

% of the labelled amount per tablet

0

months 3 months 6 months

Regal Pharmaceuticals (Cetamol) 95.6

94.6 90.4

Smith Kline Beecham (Panadol) 95.0

94.9 93.9

S&R Pharmaceuticals (Saramol) 90.8

90.1 84.3

Figure 5.1: Dissolution profiles of paracetamol formulations

before and after 3 and 6 months of storage at 40°C and 75 % RH.

|