2.3.4.5. Richon et al. (1985)

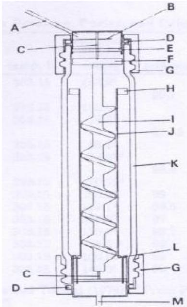

Richon et al. (1985) designed the cell presented in figure 2-6

in order to extend the use of the inert gas stripping technique to foaming and

viscous mixtures. Examples of these are aqueous mixtures of glucides, polyols

and proteins whose viscosities can be as high as 1000 cP. Since a magnetic

stirrer would be inefficient due to high viscosity, the mixture is circulated

inside the internal cylinder from top to bottom, by means of an Archimedes

screw that is maintained by two pivots and activated by a permanent magnet. A

special device is used to break foams without disturbing phase equilibrium

inside the cell. The cell is provided with a bladed screw which prevents liquid

rotation in the cell and promotes the coalescence of gas bubbles.

Figure 2-6: Dilutor cell designed by Richon et

al. (1985) for viscous and foaming mixtures.

A - vapour phase outlet, B -

deflector, C - pivot, D - gasket, E - foam-breaking device, F -

permanent

magnet, G - plug, H - bladed screw, I - Archimedes screw, J - internal

cylinder, K -

dilutor cell, L - carrier gas capillary injectors and M -

carrier gas inlet.

2.3.4.6. Bao et al. (1994)

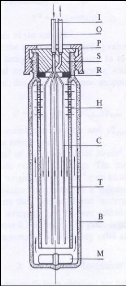

In the design given in figure 2-7 proposed by Bao et al.

(1994), a liquid-conducting tube is placed between the capillaries and the cell

body to create a countercurrent flow of circulating solution to the stripping

bubbles. This is aimed at enhancing mass transfer as well as making the

stripping process more efficient. Bao et al. (1994) used stainless steel

capillary tubes of 0.1 mm inner diameter as dispersion device.

Figure 2-7: Equilibrium cell designed by Bao

et al. (1994).

B - Body, C - capillaries, H - small holes, I - inert gas

inlet, M - magnet, O - vapour phase

outlet, P - plug, R - O-ring, S-seal, T

- liquid-conducting tube.

2.3.4.7. Hovorka and Dohnal (1997)

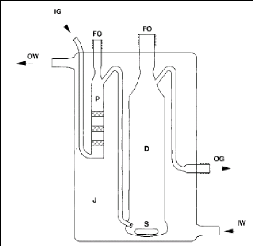

As shown in figure 2-8, Hovorka and Dohnal (1997) designed an

all-glass jacketed device accommodating both the pre-saturator and the dilutor

cell. The pre-saturation compartment is divided by fritted glass disks into

plates in order to allow efficient saturation of the inert gas with the solvent

vapour, yet maintaining a small pressure drop across it. The saturated inert

gas is dispersed in small bubbles into the diluted solution through a fine

porosity fritted glass tip. Liquid droplet entrainment is prevented by the

vapour space of the cell and a special design of the gas outlet. Their set up

allowed measuring infinite dilution activity coefficients in the range from 230

to 70000.

Figure 2-8: Equilibrium cell designed by

Hovorka et al. (1997).

P - Pre-saturator with fritted glass disks, D -

dilutor cell, S - stirrer, J - thermo-statted jacket,

IW - input of

thermo-statted water, OW - output of thermo-statted water, IG - input

of

stripping gas, OG - outlet of saturated stripping gas, FO - filling

openings.

2.3.4.8. Miyano et al (2003)

The cell shown in figure 2-9 was used by Miyano et al (2003)

to determine Henry`s law constants and the infinite dilution activity

coefficients of butane, isobutane, 1-butene and isobutene in methanol from (255

to 320) K. A counter flow of liquid against the rising bubbles is achieved in

the inner tube of the cell to increase the contact time. They used a maximum

inert gas flow rate of 2 cm3. min-1.

Figure 2-9: Equilibrium cell designed by

Miyano et al. (2003) for the determination of Henry`s

law constants using

the dilutor technique.

|