LISTE DES PLANS ET ANNEXES.

100

|

|

LABORATOIRE NATIONAL DU BATIMENT ET DES TRAVAUX

PUBLICS

|

|

IDENTIFICATION DES MATERIAUX

- RAPPORT N°0093/2015

|

PROVENANCE

|

|

|

|

|

CHANTIER

|

RN1( TRAVAUX DE REHABILITATION

|

|

Concasseur KABEZI

|

|

DES POINTS CRITIQUES SUR LA RN1

|

LOCALISATION:

|

|

|

PARTIE DE L'OUVRAGE

|

|

PROFONDEUR:

|

|

|

|

NATURE

|

|

|

DATE DE PRELEVEMENT

|

|

|

|

|

|

|

|

DATE DE L'ESSAI

|

|

|

MARS /2015

|

|

|

|

|

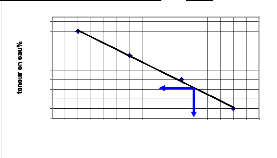

PROCTOR

|

|

|

|

|

CBR

|

|

|

|

|

RESULTATS

|

|

|

|

Nbre de coups

|

5*56

|

5*56

|

5*56

|

5*56

|

5*56

|

Nbre de coups

|

|

5*56

|

5*25

|

5*10

|

yd OPM

|

2.16

|

|

Classification

|

|

w

2.4

4.4

5.9

|

7.2

|

w

|

|

4.9

|

4.7

|

4.7

|

WOPM

|

5.6

|

LCPC

|

HRB

|

|

yd

|

2.08

|

2.13

|

2.16

|

2.05

|

|

yd

|

|

2.15

|

2.03

|

1.92

|

|

|

|

|

|

|

|

|

|

|

CBR

|

|

97

|

63

|

35

|

90%yd OPM

|

1.94

|

CBR=

|

40

|

|

W imbibée

|

gonflement %

|

|

4.9

4.7

4.7

95%yd OPM

2.05

0

98%yd OPM

2.12

|

CBR=

CBR=

|

68

88

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.1

2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

lo

|

|

|

|

|

2.15

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.05

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.9

30 40

|

|

|

50

|

60

|

70

|

80

|

|

90

100

|

|

2

2.0

|

3.0

|

4.0 5.0

|

6.0

|

|

7.0

|

|

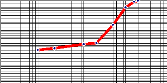

poinçonnement

|

|

W%

capacité de

|

l'anneau

|

en

|

|

|

|

|

|

|

coefficient

|

CBR

|

|

|

masse

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

KN

|

30

|

série N°

|

|

|

4415

|

|

|

k

|

|

0.2098

|

|

du moulage

|

|

enfoncement

|

0.25

|

0.5

|

1

|

1.5

|

2

|

2.5

|

3

|

4

|

5

|

6

|

|

7

|

|

8

|

9

|

résultats

|

|

0h

|

96h

|

|

5*56

|

|

5

|

10

|

18

|

24

|

29

|

37

|

59

|

92

|

105

|

|

112

|

|

121

|

130

|

CBR=

|

96.8

|

11480

|

11480

|

|

5*25

|

2.5

|

5

9

|

13

|

21

|

20

44

|

60

82

|

104

|

|

130

|

143

|

CBR=

|

63.1

|

10890

|

10890

|

|

5*10

|

2

|

4

6

|

10

|

13

|

17

24

|

33

43

|

53

|

|

|

63

73

|

CBR=

|

34.7

|

10500

|

10500

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

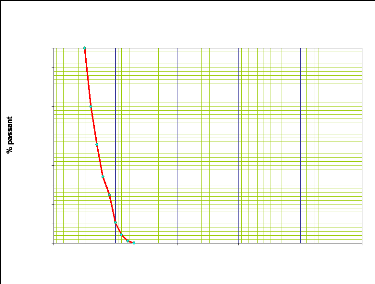

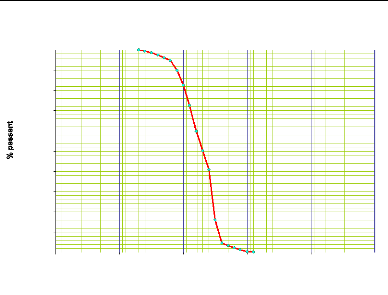

ANALYSE GRANULOMETRIQUE

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dia

|

0.08

|

0.2

|

0.63

|

2

|

5

|

10

|

12.5

|

25

|

31.5

|

|

|

|

|

|

|

|

|

|

|

%

1

3.5

12.3

|

21.4

39.1

0 1.18

|

63.2

|

73

96.5

|

100

|

|

|

|

|

|

|

|

|

|

|

|

0 courbe d'analyse

118

|

|

|

|

granulométrique

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2100

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90

3 2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4580

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7670

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 98

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 60

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 1

1 50

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 4540

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 30

20

10

|

0

0.01 0.1 1 10 100

ANNEXE 1

ANNEXE 2

101

|

LABORATOIRE NATIONAL DU BATIMENT ET DES TRAVAUX

PUBLICS

|

|

|

IDENTIFICATION DES MATERIAUX

-

|

|

|

CHANTIER

|

BOULEVARD DE MWAMBUTSA

|

PROVENANCE :PK 0+800 CG

|

|

|

OPERATEUR

|

IGIRUKWISHAKA MOISE et Isaac

|

LOCALISATION

|

P1

|

|

|

OUVRAGE

|

ROUTE

|

PROFONDEUR

|

0,40-0,80 m

|

|

|

PARTIE DE L'OUVRAGE

|

Plate forme

|

NATURE

|

|

|

|

CLIENT

|

|

DATE DE L'ESSAI

|

NOVEMBRE/2016

|

|

|

PROCTOR

|

CBR

|

|

|

RESULTATS

|

|

|

Nbre de coups

|

5*56

|

5*56

|

5*56

|

5*56

|

5*56

|

Nbre de coups

|

5*56

|

5*25

|

5*10

|

yd OPM

|

1.56

|

Classification

|

|

|

w

|

18

|

20.5

|

22.5

|

24.6

|

|

w

|

22.4

|

22.3

|

22.1

|

WOPM

|

22

|

LCPC

|

HRB

|

|

|

yd

|

|

1.55

|

1.56

|

1.47

|

|

yd

|

1.58

|

1.53

|

1.33

|

|

|

Ap

|

A6

|

|

|

COURBE

|

DE

|

|

SATURATION

|

|

|

CBR

|

42

|

25

|

10

|

90%yd OPM

|

1.41

|

CBR=

|

16

|

|

|

1.49

|

|

|

|

|

|

W imbibée

|

25.9

|

26.3

|

34.1

|

95%yd OPM

|

1.48

|

CBR=

|

21.5

|

|

|

|

|

|

|

|

gonflement %

|

|

0.535

|

|

98%yd OPM

|

1.53

|

CBR=

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.58

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a~

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32

|

|

i 1.56

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

wCD

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 1.54

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 1.51

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 1.52

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

d 1.5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m 1.41

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Iw

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

É

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.48

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.46

17.6

|

|

18.6

|

|

19.6

|

|

20.6

|

21.6

|

22.6

|

|

23.6

|

|

24.6

|

1.31

10

|

|

14

18

|

22

|

26 30

|

34 38

|

42

|

|

|

|

|

|

|

|

|

|

W%

|

|

|

|

|

|

|

|

|

|

CBR

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

poinçonnement

|

|

|

|

|

|

|

capacité

|

de

l'anneau

|

|

|

en

|

KN

|

30

|

série

|

N°

|

4415

|

coefficient

|

k

|

|

0.2098

|

masse

|

du moulage

|

|

|

enfoncement

|

|

0.25

|

|

0.5

|

|

1

|

1.5

|

2

|

|

2.5

|

|

3

|

4

|

5

|

|

6 7

|

8

|

9

|

résultats

|

|

0h

|

96h

|

|

|

ôr

|

5*56

|

|

|

|

4

|

|

13.5

|

20

|

24

|

|

27

|

|

29

|

32.5

|

35.5

|

38

|

40

|

42.5

|

44.5

|

CBR=

|

42.4

|

11930

|

12045

|

|

|

ro

M

|

5*25

|

|

|

|

2

|

|

4

|

7

|

12

|

|

16

|

|

18

|

20

|

23

|

26

|

29

|

32

|

34

|

CBR=

|

25.1

|

10330

|

10460

|

|

|

o

E

|

5*10

|

|

|

|

1

|

|

2.5

|

5

|

6

|

|

6.5

|

|

6.5

|

7

|

7.5

|

|

8 8.5

|

8.5

|

9

|

CBR=

|

10.2

|

9140

|

9475

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ANALYSE

|

|

|

|

|

GRANULOMETRIQUE

|

|

|

|

|

|

LIMITES DE

|

|

LIQUIDITE"WL"

|

|

|

|

|

RESULTAT

|

|

|

Dia

|

0.08

|

|

0.2

|

|

0.4

|

|

0.5

|

1

|

1.6

|

|

|

2

|

2.5

|

Nbre de coup

|

16.0

|

20.0

|

24.0

|

28.0

|

|

WL

|

33.90

|

|

|

%

|

62.4

|

|

65.8

|

|

80.9

|

|

87.5

|

97.3

|

98.5

|

|

98.6

|

|

100

|

|

|

|

|

|

|

|

|

Wp

|

21.40

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

courbe

|

|

|

d'analyse

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

teneur en eau

|

|

|

|

36.0

|

|

35.1

|

|

34.3

|

|

33.1

|

|

|

Ip

|

|

|

|

12.50

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6

|

|

0

|

|

1

118

|

granulométrique

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

35.9

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

00

1.2

.2

.3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90

2

503

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.

80

.2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

34.9

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.3

10

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

eu40

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.

. .4

30

4

40

|

|

|

|

|

|

|

100

|

33.9

|

|

|

|

|

|

|

|

|

|

. . 20 4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.

|

|

ouvertures

|

des

|

mailles

|

en mm

|

|

|

|

|

Nbre

|

de coup

|

|

|

|

|

|

|

.

4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8

|

|

|

|

|

|

|

|

32.9

Wn ###

14 15 16

|

17 18

|

19 20

|

21 22

|

23 24

|

25 26

|

27 28

|

29 30

|

|

|

49

0.01

51

|

|

0.1

|

|

1

|

10

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.67

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RESULTAT

LIMITES DE LIQUIDITE"WL"

ANALYSE GRANULOMETRIQUE

|

Dia 0.08

|

0.2

|

1

|

2

|

5

|

10

|

16

|

20

|

|

% 40.3

|

42.4

|

47.4

|

48.6

|

70.8

|

91.8

|

98.5

|

100

|

Nbre de coup

teneur en eau

16.0

34.3

20.0

33.8

24.0

33.3

28.0

32.7

WL

Wp

Ip

20.40

33.10

12.70

.

courbe d'analyse granulométrique

6 0

17 118

4 0.01 90.1 1 10 100

1

ouvertures des mailles en mm

. .2

100 90 .2 . 2 80 . 2

70 . . 3 60 . . 50. 40 . . 3

30 . 20 . .4 . 4 10 4

40

Wn

32.5

34.5

33.5

14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

###

Nbre de coup

1.67

ANNEXE 3

102

|

LABORATOIRE NATIONAL DU BATIMENT ET DES TRAVAUX

PUBLICS

|

|

IDENTIFICATION DES MATERIAUX

|

|

CHANTIER

|

BOULEVARD DE MWAMBUTSE

|

PROVENANCE :PK 1+400 CG

|

|

OPERATEUR

|

IGIRUKWISHAKA Moise et Isaac

|

LOCALISATION

|

P2

|

|

OUVRAGE

|

ROUTE

|

PROFONDEUR

|

0,60-1,00 m

|

|

PARTIE DE L'OUVRAGE

|

Plate forme

|

NATURE

|

|

|

CLIENT

|

|

DATE DE L'ESSAI

|

Novembre/2016

|

|

PROCTOR

|

CBR

|

RESULTATS

|

|

Nbre de coups

|

5*56

|

5*56

|

5*56

|

5*56

|

5*56

|

Nbre de coups

|

5*56

|

5*25

|

5*10

|

yd OPM

|

1.72

|

Classification

|

|

w

|

10.5

|

12.9

|

14.8

|

16.3

|

|

w

|

14.9

|

14.1

|

13.8

|

WOPM

|

14.8

|

LCPC

|

HRB

|

|

yd

|

1.6

|

1.66

|

1.72

|

1.64

|

|

yd

|

1.71

|

1.67

|

1.43

|

|

|

GA

|

A6

|

|

COURBE DE SATURATION

|

|

|

CBR

|

20

|

17

|

11

|

90%yd OPM

|

1.55

|

CBR=

|

13.6

|

|

|

|

|

|

|

W imbibée

|

15.2

|

16.4

|

19.3

|

95%yd OPM

|

1.63

|

CBR=

|

15.5

|

|

|

|

|

|

|

gonflement %

|

|

0.157

|

|

98%yd OPM

|

1.69

|

CBR=

|

18.5

|

|

1.74

|

|

|

|

|

|

|

1.71

.o

V

uni

. 1.61

g

> 1.51

e

E

1.41

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.o 1.72

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.7

uni

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

'. 1.68

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

g 1.66

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o 1.64

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

>>

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i 1.62

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.6

E

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.58

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 11 12 13 14 15 16

W%

|

10 11 12 13 14 15 16 17 18

CBR

|

19 20 21 22

|

|

poinçonnement

|

capacité de l'anneau en KN 30

|

série N°

|

4415

|

coefficient k

|

|

0.2098

|

masse du moulage

|

|

enfoncement

|

0.25

|

0.5

|

1

|

1.5

|

2

|

2.5

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

résultats

|

|

0h

|

96h

|

|

'11of

ta 3 0 E

|

5*56

|

|

2.5

|

3

|

5

|

8

|

12

|

15

|

17

|

19

|

25

|

29

|

30

|

35

|

CBR=

|

20.0

|

12990

|

13000

|

|

5*25

|

|

1.5

|

2

|

4

|

6

|

8

|

12

|

14

|

16

|

19

|

21

|

25

|

27

|

CBR=

|

16.8

|

11780

|

11860

|

|

5*10

|

|

1

|

1

|

2

|

3

|

4

|

6

|

8

|

10

|

13

|

16

|

18

|

21

|

CBR=

|

10.5

|

10935

|

11100

|

103

ANNEXE 4

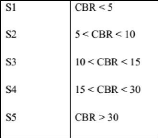

Chantier :

RN 1 Client: CIRA

Localisation : PK

21+600 Dossier: 0573/2013

Provenance : gravier de

Rivière MUHUNGUZI (MAGEYO)

Analyse granulométrique

63.00

50.00

40.00

Ø Tamis

31.50

100.000

60.000

40.000

20.000

90.000

80.000

70.000

50.000

30.000

10.000

0.000

100.00 10.00

Analyse granulométrique

1.00 0.10

Diamètre tamis

0.01 0.00

25.00

20.00

16.00 12.50 10.00

8.00 6.30 5.00

4.00

3.15 2.50

2.00 1.60 1.25 1.00 0.80

0.63 0.50 0.40 0.32 0.25

0.20 0.16 0.13 0.10

0.08

% passant

100.0

70.0

50.7

34.2

24.9

10.7

4.4

1.2

0.1

104

ANNEXE5

Chantier :

RN 1 Client: CIRA

Localisation : PK

21+600 Dossier: 0573/2013

Provenance : Sable de

Rivière MUHUNGUZI (MAGEYO)

Analyse granulométrique

63.00

50.00

40.00

31.50

25.00

Ø Tamis

20.00

100.000

60.000

40.000

20.000

90.000

80.000

70.000

50.000

30.000

10.000

0.000

100.00 10.00

Analyse granulométrique

1.00 0.10

Diamètre tamis

0.01 0.00

16.00 12.50 10.00

8.00 6.30

5.00

4.00

3.15

2.50

0.40

2.00

0.32

1.60

0.25

1.25

0.20

1.00

0.16

0.80

0.13

0.63

0.10

0.50

0.08

% passant

100.0

99.4

98.6

97.5

96.1

94.8

89.9

82.6

72.6

59.9

50.2

40.9

16.0

4.6

3.4

2.3

1.3

0.4

0.2

105

|

LABORATOIRE NATIONAL DU BATIMENT ET DES TRAVAUX

PUBLICS

|

|

ANNEXE 6

|

|

|

|

Client :

CIRA

|

|

Unités utilisées :

|

|

|

|

|

|

|

Masses granulaires et masses des prises d'essai

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

|

|

|

|

(1)

|

500

|

7

|

2900 à 3100

|

|

|

ESSAIS LOS ANGELES

|

|

|

|

|

|

|

|

|

(2)

|

500

|

9

|

3810 à 3980

|

|

|

|

|

|

|

|

|

|

|

|

Chantier : RN 1 PK17+650 CD (Benga)

Echantillon : Roche ( Concassé 10/14

)

(3)

|

500

|

11

|

4690 à 4860

|

|

|

|

+

|

|

|

|

|

|

|

|

(4)

|

500

|

11

|

4690 à 4860

|

|

|

|

|

|

|

|

|

|

|

(5)

|

500

|

12

|

5130 à 5300

|

|

|

|

|

|

|

|

|

|

|

(6)

|

500

|

12

|

5130 à 5300

|

|

|

|

|

|

|

|

|

|

|

(1)

4/6,3

5000

(2)

6,3/10

5000

(4)

10/14

5000

(4)

10/25

5000

(5)

16/31,5

5000

(6) 25/50

5000

10/16

3000

16/25

2000

16/25

2000

25/31,

25/40

3000

40/50

2000

|

Masse

prise

d'essai

M

5000

106

|

LABORATOIRE NATIONAL DU

BATIMENT ET DES TRAVAUX

PUBLICS

|

ANNEXE 7

|

|

LNBTP

BURUNDI

|

GRANULATS ESSAI

D'USURE MICRO-DEVAL

|

Dossier n° :

0573/2013 Récept.n° :

Date : le

07/1/2014

|

|

Chantier : RN1 PK 17+650 CD

(Benga)

|

Opérateur : Vincent

|

|

Echantillon : Concassé

6,3/10 Client : CIRA

|

|

Essai :(ordre tambours de G à D :

1234?)

|

A sec

|

Avec eau

|

A sec

|

Avec eau

|

|

Masse prise d'essai (g)

|

|

500

|

|

500

|

|

Masse de la charge (g)

|

|

4000

|

|

4000

|

|

Volume d'eau (l) :

|

|

2,5

|

|

|

|

Masse refus à 1,6mm : m'(g)

|

|

400

|

|

2,5

399

|

|

Coefficient Micro-DevalMDS

MD = 500-m'

|

|

MDE

|

MDS

|

MDE

|

|

20

|

|

20.2

|

|

5

|

|

Echantillon

|

|

|

|

|

Essai : (ordre tambours de G à D :

1234?)

|

A sec

|

Avec eau

|

A sec

|

Avec eau

|

|

Masse prise d'essai (g)

|

|

|

|

|

|

Masse de la charge (g)

|

|

|

|

|

|

Volume d'eau (1) :

|

|

2,5

|

|

|

|

Masse refus à 1,6mm : m'(g)

|

|

|

|

2,5

|

|

Coefficient Micro-Deval

MD = 500-m'

|

MDS

|

MDE

|

MDS

|

MDE

|

|

|

|

|

|

5

|

|

Masse granulaire 4-6 : 500 g+2, charge :

2.000 g#177;5

Masse granulaire 6-10 : 500 g+2, charge :

4.000 g#177;5

|

|

Masse granulaire 10-14 : 500 g

+2, charge : 5.000 g#177;5

Durée de l'essai : 2 heures (+12.000 tours

en raison de 100#177;5 tr/min.)

|

|

OBSERVATIONS :

Début de l'essai : 8 h14' Fin de l'essai

: 10h14'

|

|

MDS : MDE : 20.1

|

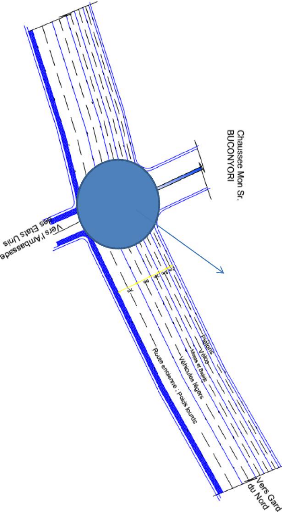

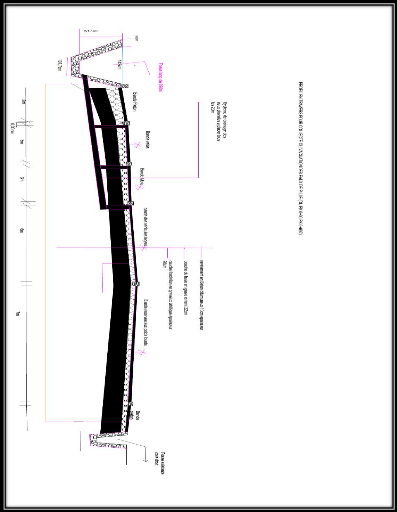

CARREFOUR A AMENAGER

107 ANNEXE 8

108

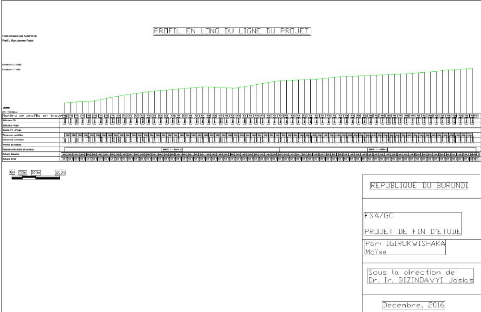

ANNEXE 9

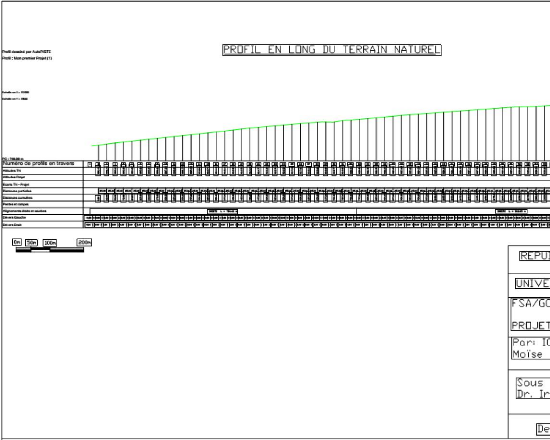

ANNEXE 10

109

ANNEXE 11

110

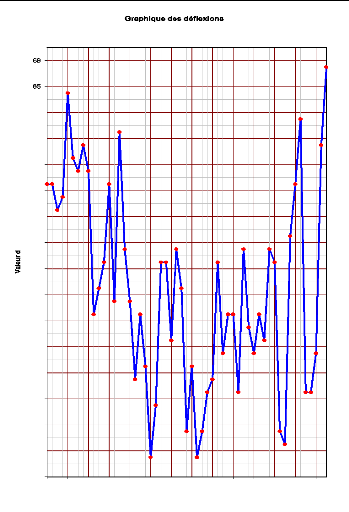

alur d

A 17 34

D 19 38 A 25 50 G 16 32 A

29 58

D 20 40

A 16 32 G 10 20 A 15 30 D

11 22 A 4 8 G 8 16 A 19 38 D 19

38 A 13 26 G 20 40

A 17 34 D 6 12 A 11 22 G 4

8 A 6 12 D 9 18 A 10 20 G 19

38

500 550 600 650

700 750 800 850 900

950 1 000 1 050 1 100 1

150 1 200 1 250 1 300 1 350

1 400 1 450 1 500 1 550 1

600 1 650

A 12 24

1 700

61

D 15 30

1 750

des0

1 800

A 15 30

b

1 850

G 9 18

57

dso

1 900

A 20 40

1 950

D 14 28

A 12 24

2 000

53

dga

2 050

G 15 30

2 100

A 13 26

dga

2 150

D 20 40

49

2 200

A 19 38

2 250

G 6 12

2 300

A 5 10

45

2 350

D 21 42

2 400

A 25 50

2 450

G 30 60

41

2 500

A 9 18

2 550

D 9 18

2 600

A 12 24

37

2 650

G 28 56

2 700

A 34 68

m

33

s

k

dr

29

25

21

rfl

17

bodesds

13

bodgds

9

ro

ofl

re

5

34

0 200 400 600 800 1 000 1 200 1 400 1 600 1 800 2 000 2 200

2 400 2 600

15

Réference

P.K.

1.3

54

111

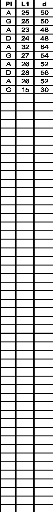

ANNEXE 12.

Classification des sols selon CEBTP

112 ANNEXE 13

ANNEXE 14

113

ANNEXE 15

114

ANNEXE 16

115

116

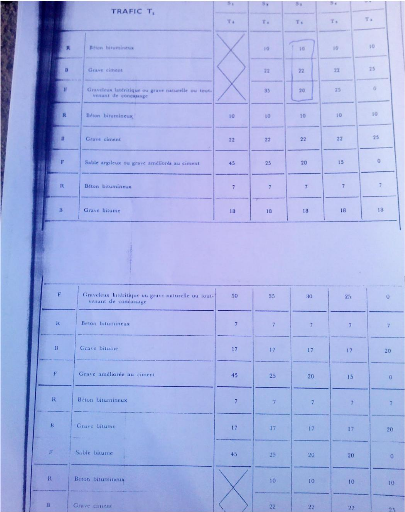

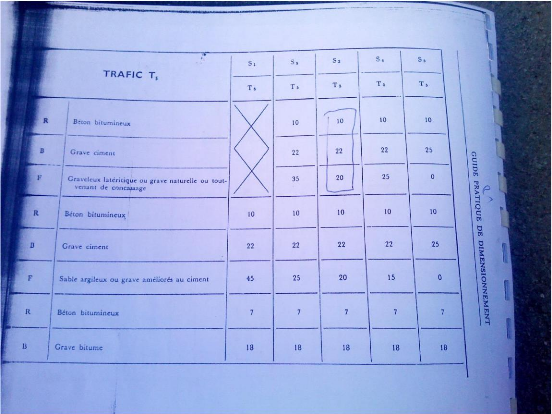

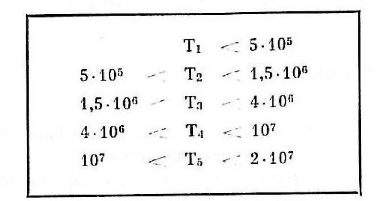

ANNEXE 17 :Trafic selon le nombre de poids lourds selon CEBTP

ANNEXE 18 :Tableau des trafics en fonction des essieux

standard selon CEBTP

117

|