PEOPLE'S DEMOCRATIC REPUBLIC OF ALGERIA

Ministry of Higher

Education and Scientific Research

|

M'Hamed Bougara University

Faculty of Hydrocarbons

and Chemistry

|

|

Department of Hydrocarbon Transportation and

Equipment

Master Degree Dissertation

Field : Technical Sciences

Sector :

Hydrocarbons

Specialty : Mechanical

Engineering

Option : Oil Fields Mechanics

Presented by: CHEMAA Khaled

CHABANI Yacine

THEME:

Study of tribological properties of titanium-based thin

films applied to the rubbing parts of internal combustion

engines piston

Defended publicly on the 07/04/2017

Before the jury:

Gaceb Mohamed (Professor UMBB) President of the jury

Gaceb Mohamed (Professor UMBB) Framer

Hassani Salim (Research Fellow CDTA) Co- framer

Examiners member:

Benbrik Abderrahmane (Professor UMBB) Examener

Harhout Riyad (Assistant Professor UMBB) Examener

Boumerdes 2017

«Allah will raise up to

ranks, those of you

who believe and who

have been granted

Knowledge»

The Holy Quran [58:11]

II

Acknowledgement

Acknowledgement

First of all we want to thank the almighty Allah for the

blessing of health, knowledge and reason, and for huge opportunities gave us

during our lifetime;

We want to thank our parents for the great sacrifices they made

for us;

One of the biggest opportunities of Allah is that he made us

studying in the faculty of hydrocarbons and chemistry of BOUMERDES (ex-INHC),

where we had the pleasure of meeting great people, who sacrifice by their

money, their time and fight just to make that historical monument (which was

created in 1964) rise again despite the huge difficulties. People like Pr. M.

TAIBI, Pr. S. AISSANI, Dr. A. GUEBLI, Pr. A. ABBASSOV, Pr. A. BENBRIK, Mr. T.

HACHEMI Pr. A. BLAIDI and others, taught us indirectly what a man can do when

he has the great will and the good well to change his surrounding society;

We want to thank, particularly Pr. M. GACEB our dissertation

framer, and our honorable professor, first of all because he awakened us when

we were in a deep sleep, then he guided and helped us (and anyone who seek for

knowledge and they are few) with everything he can for the sake of science, we

wish him good health to help our successors for years to come;

We want to thank Dr. S. HASSANI our dissertation co-framer and

the responsible of Laser and Ionized Medium at the CDTA center, it was a great

opportunity to work with someone who have such a knowledge, despite the short

the time which didn't allow us to learn more from his great knowledge and

experience;

We want to thank all people who help us to fulfil our

dissertation, beginning by Pr. Abdi from the Mechanical Engineering Department

of the USTHB who allowed us to use their tribometer, our professor Dr. A.

GUEBLI who enriched us with his valuable advice, Mr. DRISS of CDTA Center who

helped us with the thin film deposition process, and all the CDTA members and

staffs;

|

ìáÇ

ÉÇÖáÅÇÈ ÇÏÌ

|

ÉíáÇÚ

ÉíáÚÇÊæ

|

ÉãÇå

ÉíÚæä ÉíÍØÓ

ÉÍÇÓã

ßáÊãÊ

|

ÉÞíÞÑáÇ

|

ÉíÔÛáÇ

|

ÉíÑÊãæäÇäáÇ

|

|

äã:ÕÎáã

ÇÞáÇØäÇ

|

.ÇÏÌ

ÉÒíãã

ÉíäæÑÊßáÅ æ

ÉíÑÕÈ æ

ÉíßíäÇßíã

ÕÆÇÕÎ

|

ÁÇÑÊåáÇÇæ

ßÇßÊÍáÇÇ äÚ

ÉÌÊÇäáÇ

ÑÆÇÓÎáÇ

|

äã

|

ÏÍáÇÈ

ÍãÓÊ

íáÎÇÏáÇ

ÞÇÑÊÍáÇÇ

ÊÇßÑÍã

ÉÚÇäÕ í

ÇíÌæáæäßÊáÇ

|

åÐå

|

ÞíÈØÊ

|

|

.ááÇÛÊÓáÇÇ

|

æ

|

ÌÇÊäáÅÇ

ÉáÍÑã

|

í

|

ÁÇæÓ

|

ÉáßÊáÇ

|

ìáÚ

|

ÑÔÇÈã

|

áßÔÈ ÑËÄí

Çãã

ÉáãÚÊÓãáÇ

ÏÇæãáÇ äã

ÑÏÞ áÞÈ ßáÐæ

|

ÇåÏÇÚÈ

III

.íáÎÇÏáÇ

ÞÇÑÊÍáÇÇ

ÊÇßÑÍã

ÓÈÇßãáÇ

ÉíßÇßÊÍÇ

ÕÆÇÕÎ

ÑÇÎÈáá

íÆÇíÒíáÇ

ÈíÓÑÊáÇ

ÉÞíÞÑáÇ

ÉíÔÛáÇ

:ÉíÍÇÊã

ÊÇãáß

Abstract:

Because of their nanometric dimensions, thin films have a

very high specific, a very high reactivity and exceptional mechanical, optical

and electronic properties.

The application of this technology in the internal

combustion engine industry reduces losses of friction and wear with a low loss

of material, which directly influences on the cost, whether during production

phase or during the service.

Keywords: Thin film, physical vapor deposition (PVD),

tribological properties, pistons, internal combustion engines.

Résumé:

De par leurs dimensions nanométriques, les

couches minces présentent une très grande surface

spécifique, une réactivité très

élevée et des propriétés mécaniques,

optiques et électroniques exceptionnelles.

L'application de cette technologie en industrie des

moteurs à combustion interne permet de réduire les pertes par

frottement et usure avec une faible perte de matière ce qui influencer

directement sur le coût, que ce soit a la phase de production ou de

l'exploitation.

Mots clés: Couche mince, dépôt

physique en phase vapeur (PVD), propriétés tribologiques,

pistons, moteurs à combustion interne.

IV

List of symbols

List of symbols

??: Coefficient of linear expansion, Degree of ionization ratio,

Stricking coefficient;

????: Melting temperature;

??: Thermal conductivity, mean free path, the wavelength;

??: Density;

????: Electrical resistivity;

??: Stresse;

u: Poisson's ratio;

??: Constant of friction;

w: Wave frequency;

?? : Molecular diameter;

A: Area;

A%: Breaking elongation;

B : Number of intermolecular impacts;

D??: Distance;

E: Modulus of elasticity; E??: Kinetic energy;

E??: Dissipated energy;

F: Force, load;

??: Rate of return of energy;

h: Planck constant;

H: hardness;

HB: Brinell hardness;

HV: Vickers hardness;

icorr : Corrosion current density;

k : Boltzmann constant;

????: Knusden number;

??: Molecule mass;

N: Molecules number;

?? : Number density of the molecules;

??: Pressure;

??0 : The pressure at the initial instant;

????: Saturated vapor pressure;

Q: Mass flow rat;

??: Radius;

??: Radius of the wear track;

????: Breaking strength;

Re, Re0.2: Yield strength;

??: Time;

T : Temperature;

V

List of symbols

??: Rate of propagation of pits, molecules speed; ?? : The

volume;

v??2 : The-root-mean-square speed of molecules; ????:

The most probable speed of molecules; W??: Wear rate;

VI

Books list

[1] Aide-mémoire Science Des Matériaux, Michel

DUPEUX, Dunod 2008;

[2] Aide-mémoire Métallurgie, Guy MURRY, Dunod

2010;

[3] Aluminum Alloys: Structure and Properties, L. F. MONDOLFO,

Butterworths London, Boston 1976;

[4] Caractérisation par spectrométrie Raman?

Sébastien REYMOND-LARUINAZ, université de bourgogne;

[5] corrosion aspects cinétiques de la corrosion,

Université du sud Toulon-Var- institut des sciences de

l'ingénieur de Toulon et du var;

[6] Dépôts physiques : techniques, microstructure

et propriétés, Lech PAWLOWSKI, Presses Polytechniques Et

Universitaires Romandes 2003;

[7] Introduction à la Diffraction par Rayon X, Simon

HAZIZA and Emmanuelle DELEPORTE, école normale supérieure

paris-Saclay;

[8] Lubrifiant et fluids pour l'automobile, AYEL, M.BORN, French

oil institute,Technip edition;

[9] Nanomatériaux, traitement et fonctionnalisation des

surfaces, Jamal TAKADOUM, Lavoisier 2008.

[10] Physique Des Plasmas Collisionnels, Michel MOISA, CNRS

Éditions 2006;

[11] Physique des plasmas tome 1, Jean-Loup DELCROIX, CNRS

Éditions 1994;

[12] Pistons and engine testing, MAHLE GMBH, springer vieweg -

Stuttgart Germany;

[13] Techniques de l'Ingénieur : Traité

Matériaux Métalliques Aluminium et alliages d'aluminium

corroyés : propriétés métalliques, Roger

DEVELAY;

[14] Techniques de l'Ingénieur : Traité

Matériaux Métalliques Données numériques sur

l'aluminium non allié, Roger DEVELAY;

[15] Techniques de l'Ingénieur : Traité

Matériaux Métalliques Données Numériques sur les

Alliages d'Aluminium de Transformation, Roger DEVELAY;

[16] Techniques d'ingénieur : Traité

Matériaux Métalliques traitement de surface des métaux par

voix sèche et en milieu fondu, Sylvain AUDISIO;

[17] Techniques de l'Ingénieur, traité

Matériaux métalliques, Lubrification des surfaces lors de la mise

en forme, M 597, E. Felder;

[18] Traité des matériaux Tome 4 : Analyse des

surfaces, Collectif, Presses Polytechniques, Universitaires Romandes 2003;

[19] Traitements et revêtements de surface des

métaux, Robert LEVEQUE, Dunod 2007;

[20] Vide poussé au laboratoire et dans l'industrie, G.

GRIGOROV, Edition Masson & Cie 1970.

VII

References

References

[ABE 97] ABELMANN L., LODDER C., Oblique evaporation and

surface diffusion , Thin Solid Films, vol. 305,

1997;

[ALL84] ALLEN A., DUDLEY B.R., MIDDLETON V., PARKER D.A.,

Prediction of Piston Ring Cylinder Bore Oil

film Thickness in two Particular Engines and Correlation with

Experiment Evidence, Bulletin of the JSME,

1984, n° C 73174;

[AND02] ANDREETA E.R.M., RODRIGUES J.A., ANDREETA M.R.B.,

AGULLÓ-RUEDA F., HERNANDES A.C.,

Directional solidification of the Al2O3/GdAlO3 eutectic by

laser melting technique, Céramique vol.48

No.305 São Paulo Jan./Feb./Mar. 2002;

[BRO76] BROWN S R., HAMILTON G.M, Pressure Measurement between

the Rings and Cylinder Liner of an

Engine, Mechanical Engineering Publications, 1976;

[BUC67] BUCKLEY, NASA-TMX-52 279 Oct 1967;

[CHA 04] CHANG Y.Y., WANG D.Y., Corrosion behavior of CrN

coatings enhanced by niobium ion

implantation, Surface and Coatings Technology, vol. 188-189,

2004;

[CHE94] CHENR C.C., LIANG X.T., TSE W.S., CHEN I.Y., and DUH

J. G., Raman Spectra of Titanium Nitride

Thin Films, chinese jornal of physics APRIL 1994;

[CIE99] CIEMENS B. KUNG H. BARNETT S.A., Structure and

strength of multilayers, MRS Bulletin p20-26

février 1999;

[COU64] COURTEL R., métaux-corrosion-industrie

n°474-475 1964;

[DIT 91] DITCHBURN R.J., SMITH G.B., Useful angular

selectivity in oblique columnar aluminum, J. Appl.

Phys., vol. 69(6), 1991;

[DON94] DONG J., CHEN G., LUO X., CHEN L, and SHI Z.F., A new

concept formation of permeating layers

from noactive anti-wear additives, Lubr. Eng., 1994;

[DON 96] DONG L., SMITH R.W., SROLOVITZ D.J., A

two-dimensional molecular dynamics simulation of

thin film growth by oblique deposition, J. Appl. Phys., vol.

80(10), 1996;

[EUR/http]

http://www.euralliage.com/aluminium.html;

[EXP/http]

https://expertsdefaillances.com;

[FEN61] FENG I.M. and CHALK H., effect of gases and liquids in

the lubrication and surface damage, Wear,

1961;

[FOR70] FORBES E.S., The load carrying action of

organo-sulphur compounds-a review, Wear,

1970;

[FUR59] Furuhama S., A Dynamic Theory of Piston Ring

Lubrication, Bulletin of JMSE, V2, 07, 1959;

[FUR79] FURUHAMA S., TAKIGUCHI M., Measurement of Piston

Frictional Force in Actual Operating Diesel

Engine, SAE Transactions, 1979, n° 790855;

[GEO79] GEORGES J.M., MARTIN J.M., MATHIA T., KAPSA P., MEILLE

G. and MONTES H., Mechanism of

boundary lubrication with Zinc dithiophosphates, Wear,

1979;

[GER/http]

https://german.alibaba.com/product-detail/82mm-hatz-tractor-e780-enigne-piston-

60185120100.html;

[GRA08] GRAS René, tribologie, Dunod 2008;

[GRO71] GROSZEK A.J., Activation of iron surfaces by

chemisorption of some EP and anti-wear additives,

wear 1971;

[HOD 98] HODGKINSON I., Wu Q.H., MCPHUN A., Incremental-growth

model for the deposition of

spatially modulated thin film nanostructures, J. Vac. Sci.

Technol, vol. B16(5), 1998;

VIII

References

[HOL58] HOLM, J. F. ARCHARD, Wear 7, Elsevier 1958-1959;

[HOV 02] HOVSEPIAN P.E., MÛNZ W.D., Recent progress in

large-scale production of nanoscale

multilayer/superlattice hard coatings, Vacuum, vol. 69(1-3),

2002;

[HOV 05] HOVSEPIAN P.E., LEWIS D.B., Luo Q., FARINOTTI A.,

Corrosion résistance of

CrN/NbN superlattice coatings grown by various physical vapor

déposition techniques,

Thin Solid Films, vol. 488(1-2) 2005;

[IOP/http]

http://iopscience.iop.org/article/10.1088/2043-6262/2/3/035014;

[LIN 03a] LINTYMER J., Etude de l'influence de la

microstructure sur les propriétés mécaniques et

électriques de couches de chrome en zigzag

élaborées par pulvérisation cathodique, Thèse

n° 993,

université de Franche-Comté, France, 2003;

[LIN 04] LINTYMER J., MARTIN N., CHAPPE J.M., DELOBELLE P.,

TAKADOUM J., Influence of

zigzag microstructure on mechanical and electrical properties

of chromium multilayered thin films, Surf.

Coat. Technol., vol. 180-181, 2004;

[LIN 05] LINTYMER J., MARTIN N., CHAPPE J.M., DELOBELLE P.,

TAKADOUM J., Nanoindentation of

chromium zigzag thin films sputter deposited, Surf. Coat.

Technol, vol. 200, 2005;

[MAL 96] MALAURIE A., BESSAUDOU A., Numerical simulation of

the characteristics of the

différent metallic species falling on the growing film

in DC magnetron sputtering, Thin

Solid Films, vol. 286, 1996;

[MBI 95] MBISE G.W., NIKLASSON G.A., GRANQVIST C.G., Obliquely

evaporated Cr films with large angular

selectivity, J. Appl. Phys., vol. 77(6), p. 2816-2818,

1995;

[MES84] MESSIER R., GIRI A. P., and ROY R. A., Revised

structure zone model for thin film physical

structure, Journal of Vacuum Science & Technology A:

Vacuum, Surfaces, and Films, 1984;

[MOV69] MOVCHAN B.A., DEMCHISHIN A.V., Study of the structure

and properties of thick vacuum

condensates of nickel, titanium, tungsten, aluminum oxide and

zirconium dioxide, Fiz. Metal. Metallovcd,

vol. 28(4), 1969;

[MYE90] MYERS J.E., BORMAN G.L., MYERS P.S., Measurement of

Oil Film Thickness and Liner

Temperature at Top Ring Reversal in a Diesel Engine, SAE

Paper, 1990, n° 900813;

[PAN85] PANDAZARAS C., Modélisation théorique et

expérimentale du frottement segments-chemise,

Thèse Doc. Inge: Institut Supérieur des

Matériaux et de la Construction Mécanique, 1985;

[PAP98] PAPAY A.G., Antiwear and Extreme-pressure Additives in

Lubricants, Lubrication science, 1998;

[RAY 74] Raynal B., Les essais des moteurs à combustion

interne, IFP- ENSPM Edition

Aout 1974;

[RES/http]

https://www.researchgate.net/figure/261063964_fig3_Figure-3-Raman-Spectra-of-Tungsten-

Oxide-Nanowires;

[REI07] REINHARD C, EHIASARIAN A.P., HOVSEPIAN P.E., CrN/NbN

superlattice structured coatings with

enhanced corrosion résistance achieved by high power

impulse magnetron sputtering interface pre-

treatment, Thin Solid Films, vol. 515(7-8), 2007;

[RIC82] RICHEZ M.F., CONSTANTS B., WINQUISH K.,Theoretical an

Experimental Study of Ring-Liner

Friction (Proceeding of 9 the Leeds Lyon) Symposium on

Tribology and Traction, sep 1982;

[ROG61] ROGOWSKI A.R., Method of Measurement of the

Instantaneous Friction of Piston-Rings in a

Firing Engine, SAE Paper 1961, n°379F;

[SET 01] SETO M.W., DlCK B., BRETT M.J., Microsprings and

microcantilevers: studies of mechanical

response », J. Micromech. Microeng, vol. 11, 2001;

[TAI 92] TAIT R.N., SMY T., BRETT J.M., Structural anisotropy

in oblique incidence thin metal films, J. Vac.

Sci. Technol, vol. A(10)4,1992;

IX

References

[TAK08/A]Jamal Takadoum, Nanomatériaux, traitement et

fonctionnalisation des surfaces, p258; [TAK08/B] Jamal Takadoum,

Nanomatériaux, traitement et fonctionnalisation des surfaces, p257;

[TAN07] TANNOUS Johny, Lubrification par les composés

organo-soufrés en phase gazeuse : Approche de la lubrification dans la

coupe des métaux, thèse de doctorat Présentée

devant L'école centrale de Lyon 2007;

[THO 74] THORNTON J.A., Influence of apparatus geometry and

deposition conditions on the structure and topography of thick sputtered

coatings, J. Vac. Sci. Technol, vol. 11(4), 1974;

[THO77] THORNTON J.A. high rate thick film growth, annual rev. of

mater, sci., vol.7, p. 239-260, 1977; [TRO 03] TROFIMOV V.I., Morphology

évolution in a growing film, Thin Solid Films, vol. 428, 2003; [WHE78]

WHEELER D., X-ray photoelectron spectroscopic study of surface chemistry of

dibenzyl disulfide on steel under mild and severe wear conditions, Wear,

1978;

[WEI00] WEI H., LIUZ., YAOK., The influence of the incidence

energy of deposited particles on the growth morphology of thin films, Vacuum,

vol. 57, 2000.

[URA87] URAS H.M, Patterson (D), Effect of Some Pistons Variables

on Piston and Ring Assembly Friction, SAE Paper, 1987, n°870088;

X

Figures list

List of Figures

Fig.1.1 MAHLE GMBH-pistons and engine testing

2nd edition- springer vieweg - STUTTGART

GERMANY.

Fig.1.2 MAHLE GMBH - pistons and engine

testing 2nd edition-springer vieweg-STUTTGART

GERMANY.

Fig.1.3 MAHLE GMBH - pistons and engine

testing 2nd edition-springer vieweg-STUTTGART

GERMANY.

Fig.1.4 MAHLE GMBH - pistons and engine

testing 2nd edition-springer vieweg-STUTTGART

GERMANY.

Fig.1.5 MAHLE GMBH - pistons and engine

testing 2nd edition-springer vieweg-STUTTGART

GERMANY.

Fig.1.6 MAHLE GMBH - pistons and engine

testing 2nd edition-springer vieweg-STUTTGART

GERMAny.

Fig.1.7 MAHLE GMBH - pistons and engine

testing 2nd edition-springer vieweg-STUTTGART

GERMAny.

Fig.1.8 J.AYEL - M.BORN - lubrifiant et

fluids pour l'automobile- French oil institute- Technip

edition.

Fig.1.9 J.AYEL - M.BORN - lubrifiant et

fluids pour l'automobile- French oil institute- Technip

edition.

Fig.1.10 J.AYEL - M.BORN - lubrifiant et

fluids pour l'automobile- French oil institute- Technip

edition.

Fig.1.11 J.AYEL - M.BORN - lubrifiant et

fluids pour l'automobile- French oil institute- Technip

edition.

Fig.1.12

https://expertsdefaillances.com

Fig.1.13

https://expertsdefaillances.com

Fig.1.14

https://expertsdefaillances.com

Fig.2.1. Aluminum Alloys: Structure and

Properties / L. F. Mondolfo / BUTTERWORTHS LONDON-

BOSTON 1976

Fig.3.1. Vide poussé au laboratoire et

dans l'industrie

Fig.3.2. Traité des matériaux

Tome 4 : Analyse des surfaces

Fig.3.3. Techniques du vide/ Simone Cassette/

cours sur internet

Fig.3.4. Vide poussé au laboratoire et

dans l'industrie

Fig.3.5. Dépôts physiques :

techniques, microstructure et propriétés

Fig.3.6. Dépôts physiques :

techniques, microstructure et propriétés

Fig.3.7. Techniques d'ingénieur :

Traité Matériaux Métalliques traitement de surface des

métaux

par voix sèche et en milieu fondu

Fig.3.8. Techniques d'ingénieur :

Traité Matériaux Métalliques traitement de surface des

métaux

par voix sèche et en milieu fondu

Fig.3.9.

institut-numerique.org

XI

Figures list

Fig.3.10.

institut-numerique.org

Fig.3.11.

institut-numerique.org

Fig.3.12.

Institut-numerique.org

Fig.3.13.

Institut-numerique.org

Fig.3.14. Traité des matériaux

tome 4 : analyse des surfaces Fig.3.15. Traité des

matériaux tome 4 : analyse des surfaces Fig.3.16.

Traité des matériaux tome 4 : analyse des surfaces

Fig.3.17. Traité des matériaux tome 4 : analyse

des surfaces Fig.3.18. Traité des matériaux tome

4 : analyse des surfaces Fig.3.19. Nanomatériaux,

traitement et fonctionnalisation des surfaces

Fig.3.20. Nanomatériaux, traitement et

fonctionnalisation des surfaces

Fig.3.21. Nanomatériaux, traitement et

fonctionnalisation des surfaces

XII

Tables list

List of Tables

Table1.1. Lubrification par les composés

organo-soufrés en phase gazeuse : Approche de la lubrification dans la

coupe des métaux, Johny TANNOUS, Thèse de doctorat de

l'école centrale de Lyon, 2007

Table2.1. Aide-mémoire Science Des

Matériaux / Michel Dupeux / Dunod 2008 Table2.2.

Aide-mémoire Science Des Matériaux / Michel Dupeux /

Dunod 2008

Table2.3. Techniques de l'Ingénieur :

Traité Matériaux Métalliques Données

Numériques sur les

Alliages d'Aluminium de Transformation / Roger Develay

Table2.4. Techniques de l'Ingénieur :

Traité Matériaux Métalliques Données

Numériques sur les

Alliages d'Aluminium de Transformation / Roger Develay

Table2.5. Aluminum Alloys: Structure and

Properties / L. F. Mondolfo / BUTTERWORTHS

LONDON-BOSTON 1976

Table3.1. Vide poussé au laboratoire et

dans l'industrie

Table3.2. Traitements et revêtements de

surface des métaux

Table3.3. Handbook of chemical vapor

deposition

Table3.4. Techniques d'ingénieur :

Traité Matériaux Métalliques traitement de surface des

métaux par voix sèche et en milieu fondu

Table3.5. Dépôts physiques :

techniques, microstructure et propriétés

Table3.6. Nanomatériaux, traitement et

fonctionnalisation des surfaces

Table3.7. Traitements et revêtements de

surface des métaux

XIII

Table of Contents

Table of Contents

Acknowledgement II

|

Abstract

List of symbols

Books list

References

List of Figures

List of Tables

|

III

IV

VI

VII X XII

|

Table of Contents XIII

Introduction 01

Literature review 04

Chapter 1: Overview on engine's piston 06

1.1. Piston types 07

1.1.1. Pistons for four-stroke gasoline engines

07

1.1.2. Pistons for diesel engines 08

1.2. Different forms of wear 10

Chapter 2: Aluminum and its alloys 21

2.1. Property Of non-alloyed aluminum (1000 series)

22

2.2. Aluminum alloys 22

2.2.1. Different classes of aluminum alloys

23

2.2.2. Physical properties of aluminum alloys

23

2.2.3. Mechanical properties of aluminum alloys

23

2.2.4. Standards defining aluminum alloys 26

2.3. Aluminum-Silicon Alloys (4000 series)

28

XIV

Table of Contents

Chapter 3: Vapor deposition and thin layer

characterization techniques... 30

3.1. Physical bases of the vacuum technique...31

3.1.1. Vacuum and gaseous phase of the material... 31 3.1.2. Movement and speed

of gaseous

molecules..................................................................

32

3.1.3. Basics of vacuum

technology............................................................................................

34

3.1.4. Duration of evacuation process... 35

3.2. The theory of plasmas... 36

3.3. Coating in the vapor phase (PVD, CVD)... 37

3.3.1. Chemical vapor deposition (CVD) techniques... 38 3.3.2. Physical vapor

deposition processes (PVD)... 39 3.3.3. Physical mechanism of a thin layer

formation .................................................................. 41

3.3.4. Thin film morphology... 44

3.4. Methods of microstructural characterization...46

3.4.1. Chemical characterization methods... 47 3.4.2. Crystallographic

characterization techniques... 49 3.4.3. Microstructural characterization

methods... 50 3.4.4. Characterization of mechanical properties...

52

3.5. Properties of thin films deposits

56

Chapter 4: Experimental Procedures.... 57

4.1. Determination of the sample grade...

58

4.2. Preparation of samples... 59 4.2.1. Samples

Cutting... 60 4.2.2. Samples polishing... 60 4.2.3. Chemical cleaning...

60

4.3. Thin film elaboration process... 60

4.3.1. Description of PVD sputtering installation and

working parameters.............................. 61

4.3.2. Description of PVD evaporation installation and

working parameters........................... 62 4.4. X-ray diffraction...

64

4.4.1. Characteristics of the device... 64

4.4.2. Working Principle... 64 4.5. Raman

Spectroscopy... 65 4.6. Scanning electronic microscope (SEM)...66 4.7. The

nanoindentation... 67 4.8. The tribometer analysis... 69 4.9. Electrochemical

techniques... 71

4.9.1. Equipment... 71

4.9.2. Establishment of EVANS diagrams...

72

4.9.3. Diagram E=f (log/i): EVANS

Diagram..................................................................................

73

XV

Table of Contents

Chapter 5: Results and Analysis 75

5.1. Analysis of XRD results 76

5.2. Analysis of RAMAN results 78

5.3. Morphological analysis 81

5.4. Interpretation of nanoindentation results

82

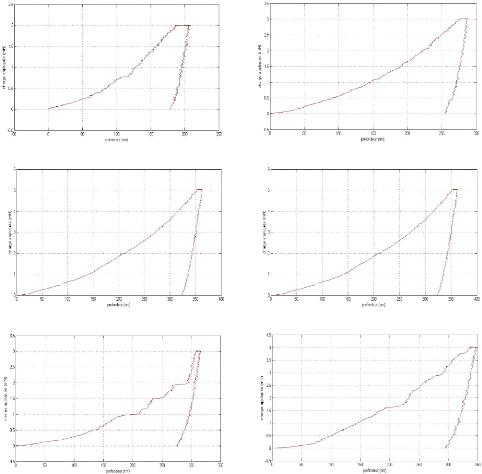

5.5. Interpretation of tribometer results 87

5.5.1. The coefficient of friction 87

5.5.2. Wear Rate 91

5.6. Corrosion test results 93

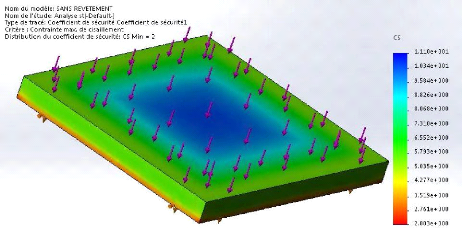

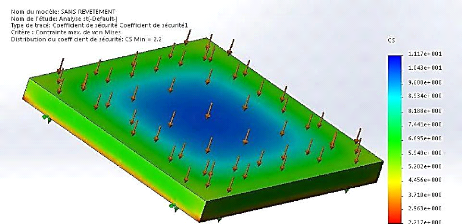

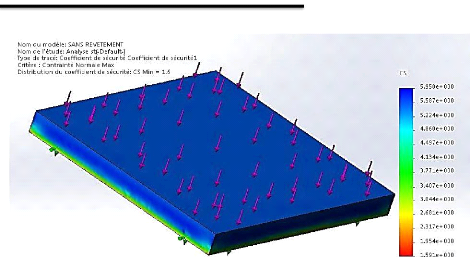

Chapter 6: Solidworks mechanical analysis of the thin

layer 95

6.1. Initial data 97

6.2. Finite element analysis of the

sample....................................................................................

97

6.3. Analysis of the result 100

Conclusion 101

Appendices AI 1

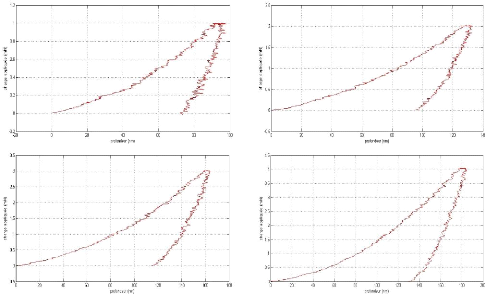

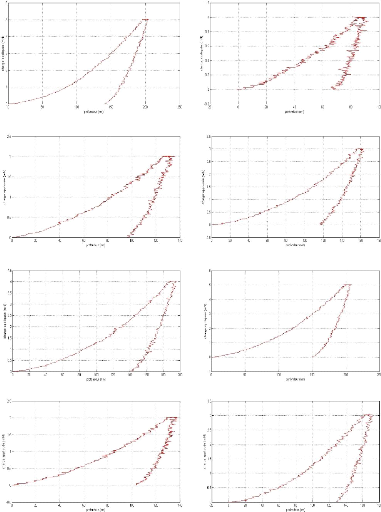

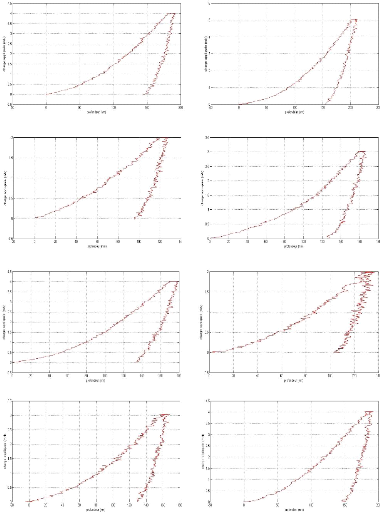

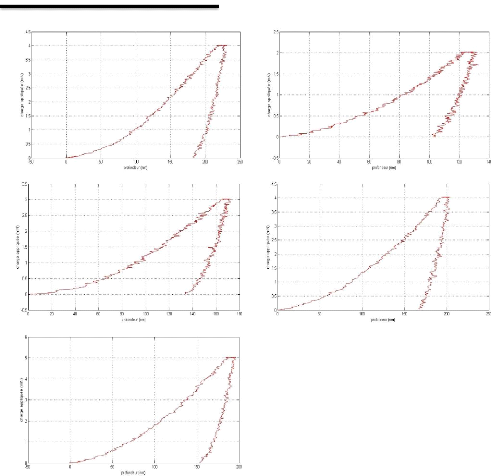

Appendix I: nanoindentation charge-discharge curves AI

2

Appendix II: Nanoindentation results . AII 1

Introduction

2

Introduction

Introduction

The thin layer technology has developed with extreme rapidity

in the last two decades whether in terms of implementation technology or

industrial applications.

In mechanical industry, the objectives of thin films are

mainly to improve the corrosion or wear resistance, to reduce the coefficient

of friction, to modify the surfaces microstructure to improve their ability to

retain lubricants and to optimize the lubrication of the rubbing surfaces and

the improvement of the aesthetic qualities of the products.

In internal combustion engines, the current trend is to save

energy, that is to say, the reduction of fuel consumption for equal or higher

power levels. To do so it is necessary to reduce friction losses between

surfaces in contact and increase their durability.

Several studies have shown that friction losses represent the

major part of the energy consumption developed in an internal combustion engine

(15 to 20%). Piston skirt friction, segmentation and bearings constitute 66% of

total friction losses; Distribution (up to 20-25% at low rpm), crankshaft,

transmission and gearbox contributing to the rest. Beyond the aspects of

reducing friction and wear, reducing oil consumption and exhaust emissions

represent ambitious challenges.

In this work, we propose to apply a thin layer of Ti-W-N on

the piston skirt and the piston crown in order to increase the surface hardness

and its corrosion resistance and to reduce the coefficient of friction.

The present dissertation contains six chapters;

The first chapter gives a brief illustration of the role of

pistons technology, and the main degradations and problems observed in pistons.

In the second chapter we present the mechanical properties of aluminum alloys,

the alloys with which the pistons are generally manufactured. In the third

chapter we describe the different thin film deposition techniques, the

tribological properties of the Ti, W and N layers, and the main deposition

characterization techniques.

In chapter four we give the different experimental procedures

executed in CDTA center, starting with the research of the probable piston

grade used as substrates in our study, passing by the preparation of the

surfaces of the samples and the deposit installations, and arriving at the

characterization of the tribological properties of our Layer (by XRD, SEM,

Raman, nanoindentation, tribometer and corrosion tests).

3

Introduction

In chapter five, we give the experimental results obtained with

their interpretation.

The chapter six dedicated to a medialization of the thin layer,

using Solidworks software, and we make mechanical test on it, in order to a

better characterization of the layer.

4

Literature review

Literature review

Hardness of titanium base thin films

Hard coatings based on nitrides (TiN, CrN, AlTiN, etc.) or

carbonitrides (TiCN) for mechanical applications came on the market in the

mid-1980s. They are characterized by a high hardness (often higher than 20 GPa)

and by great chemical inertia.

The deposited TiN/ZrN coatings have a very high hardness (>

30 GPa), much higher than the individual hardnesses of TiN and ZrN. It is noted

that the hardness increases with the Zr content in the layers, which seems

logical because the hardness of the ZrN is higher than the hardness of the TiN

with the deposition installation and the conditions used. Another interesting

result is the increase in hardness with the decrease in the individual

thickness of the alternating layers.

TiAl(N,C,O) coatings exhibit a wear behavior considerably

superior to the traditional DLC coating.

Corrosion resistance

It is well known that PVD layers generally have a columnar

structure with numerous growth defects (porosities, grain boundaries,

structural defects, etc.); thus, they do not provide adequate protection of the

corrosion-sensitive substrates.

At present, the poor corrosion resistance offered by PVD

coatings requires, on sensitive substrates, the deposition of a relatively

thick electrochemically produced undercoat. The most commonly used solution is

chromium or galvanic nickel with thicknesses of the order of 5-20

ìm.

To further improve the corrosion resistance, a Pd-Ni deposit

is applied to the nickel before the final PVD deposition. This multi-layer

process provides much better corrosion resistance, in particular, since the

galvanic undercoat is much denser and does not have a columnar structure.

However, today, and due to environmental considerations in some countries,

there is an abandonment of galvanic coatings such as nickel, zinc, cadmium,

chromium, gold and many other metals and alloys, unfortunately impossible to

replace.

Other works describe the use of an ionic etching of Nb ions

carried out by cathodic arc on ferrous substrate before PVD deposition [CHA 04;

HOV 02, 05; REI07];

The TiAl(C,O) coatings represent an interesting improvement

compared to the traditional Ti(C,O), especially since there nanohardness is

close to 13 GPa. A SEM photograph shows a dense non-columnar and amorphous

microstructure of this type of coating. This amorphous microstructure is

particularly advantageous since it generally confers a higher resistance to

corrosion of the substrate by preventing the electrolytes from passing through

the coating by the intercolonial porosities.

5

Literature review

Thin films with oblique incidence and GLAD

technical

The properties of thin layers depend primarily on their

microstructure or their nanostructure. From the first experimental studies due

to MOVCHAN and DEMICHISHIN [MOV69] and also to THORNTON [THO 74], to the recent

structural models developed by simulation [ABE 97; MAL 96; TRO 03; WEI00], the

majority of this work was mainly focused on the operating conditions

influencing the morphology and structure of films deposited under normal

incidence. Very few have been dedicated to thin films prepared under oblique

incidence [DON 96; DIT 91; HOD 98; MBI 95; TAI 92].

All this work on the layers prepared under oblique incidence

converges towards the same observation: an enlargement of the spectrum of the

physicochemical properties of the deposited materials including their stress

state, their density, their optical, electrical and magnetic anisotropy,

etc.

The work of the teams of Brett and Robbie for the production

of thin films under oblique incidence and on fixed or mobile substrate, allows

the birth of a new technic: the GLAD technical: GLancing

Angle Deposition.

The property of the GLAD technique in generating columnar

architectures of various shapes at nanometric scales leads inevitably to

questioning the mechanical behavior of these nanostructured films. Indeed, the

structural shapes of some of these architectures (example: zigzags, spirals,

etc.) give extended mechanical characteristics with respect to a conventional

columnar structure.

Using the nanoindentation tests, the authors SETO et al [SET

01] clearly show that the helically-structured films have an elastic

deformability of a higher order of magnitude compared with conventional

columnar films.

Other studies on the elastic properties of GLAD films have

also been carried out by LINTYMER and al [LIN 03a, 04, 05] on inclined and

zigzag chrome layers. In particular, it has been demonstrated that the Young's

modulus of zigzag films can be changed from single to double playing only on

the number and size of the zigzags.

Economic considerations

It is customary to say that nanomaterials are expensive, but

it must be shown that nanomaterials are additives to be used in small

quantities, the cost per function can become minimal. For example, on a square

meter, a 10 ìm coating will weigh about ten grams, adding 1%

nanomaterial will lead to 100 mg of material, even with expensive material

(1000 € / Kg for example), the cost of the coating is 1 € / Kg, which

is negligible compared to the technical, technological and functional

contribution of the layers thus realized.

Then it can be deduced that the use of nanomaterials in

surface coatings is a technological reality, which is transforming itself more

and more into economic reality.

Chapter 1

Overview on engine's piston

7

Chapter 1: Overview on engine's piston

1.1. Piston types

1.1.1. Pistons for four-stroke gasoline engines:

Modern gasoline engines employ lightweight designs with

symmetrical or asymmetrical skirt profiles and potentially different wall

thicknesses for the thrust and antithrust sides. These piston types are

characterized by low weight and particular flexibility in the central and lower

skirt areas.

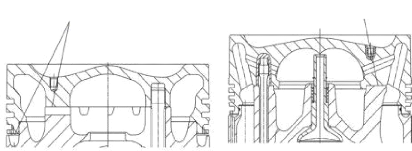

Fig.1.1: Autotermique piston

1.1.1.1. Controlled-expansion pistons

Controlled-expansion pistons are pistons with struts that

control thermal expansion. They are installed in gray cast iron crankcases. The

main target of controlled-expansion piston designs, and many inventions in this

field, was and still is to reduce the relatively large differences in thermal

expansion between the gray cast iron crankcase and the aluminium piston

We distinguish in this category the Autothermic pistons,

slotted at the transition from the piston crown to the skirt, at the height of

the oil ring groove. They are characterized by their particularly quiet running

behaviour.

The unalloyed steel struts cast in between the skirt and the

piston pin boss, together with the light alloy that surrounds them, form

control elements. They reduce the thermal expansion of the skirt in the

direction that is critical for the

Fig.1.2: BOX-type piston

guiding of the piston in the cylinder.

1.1.1.2. Box-type pistons:

Compared with controlled-expansion pistons, this piston type

is characterized by its reduced mass, optimized support, and box-like, often

slightly oval skirt design. The box-type piston is compatible with both

aluminium and grey cast iron crankcases. With a flexible skirt design, the

difference in thermal expansion between the gray cast iron crank case and the

aluminium piston can be compensated very well in the elastic range. If the box

width is different on the thrust and antithrust sides, the piston is referred

to as an asymmetrical duct piston. Box-type pistons are cast or forged.

1.1.1.3. Forged aluminum pistons:

In engines with very high power densities--such as highly

loaded

turbocharged gasoline engines--cast pistons reach their

limits. Forged pistons are a particularly good fit for this area of

application; Figure 1.15. Their strength advantage in the temperature range of

up to about 250°C improves the load carrying capacity for lateral forces,

and increases the load carrying

8

Chapter 1: Overview on engine's piston

capacity of the pin bore and the fracture toughness. Forged

pistons are therefore especially well suited for high-speed concepts and

turbocharged engines. Because of the high ductility of the forged material,

they also react more tolerantly peak pressures that can arise if an engine is

operated very close to the knock limit. This allows lower ring land widths,

among other things, and therefore lower compression heights. Since the

manufacturing process is very stable, the forged pistons can be designed to the

limit in order to minimize component weight.

|

1.1.2. Pistons for diesel engines 1.1.2.1. Ring

carrier pistons

Ring carrier pistons; have been in use since 1931. The first

and at times even the second piston ring are guided in a ring carrier that is

securely joined to the piston material by metallic bonding.

The ring carrier is made of an austenitic cast iron with a

similar coefficient of thermal expansion to that of the piston material. The

material is particularly resistant to frictional and impact wear. The top ring

groove, which is the most vulnerable, and the piston ring inserted in it are

thereby effectively protected against excessive wear. This is particularly

advantageous at high operating temperatures and pressures, which are

particularly prevalent in diesel engines.

|

|

|

Fig 1.3: Ring carrier piston

|

Fig.1.4: Ring carrier piston with cooling gallery

1.1.2.2. Cooling gallery pistons

The cooling gap inside the piston head is generally used to

optimize heat extraction. The high-speed collision of the engine oil on the

gallery surfaces improves the heat transfer capacity due to the impact caused

by the movement inside the cylinder. The heat flux removed by the cooling

gallery can reach 60% to 70% of the total heat transmitted to the piston by the

combustion gases, thereby effectively reducing the thermal loading of the

piston. When the engine is running, the cooling oil is injected from the oil

jet nozzle into the gallery through the inlet hole, flows in the

circumferential direction and exits the gallery through the exit hole, the

cooling oil does not fill the piston galley, the cooling oil exits the gallery

at high speed under the inertia of the movement

However, the structure of the cooling gallery limits to some

extent the resistance of the piston. With the steady increase in the maximum

pressure inside the diesel engine there is also the prolonged exposure of the

engine oil to higher temperatures in the piston cooling gallery which causes a

degradation of the characteristics of the lubricant which will not only affect

the piston but all engine components and carbon build-up, thereby reducing

cooling efficiency and resulting in overheating.

9

Chapter 1: Overview on engine's piston

|

1.1.2.3. Optimized monobloc steel

pistons:

This piston type is a single-piece forged steel piston that is

greatly weight optimized. With a small compression height (to less than 50% of

the cylinder diameter) and machining above the pin boss spacing (internal), the

piston mass, including the piston pin, almost corresponds to the mass of a

comparable aluminium piston with piston pin. In order to improve the piston

cooling, the outer cooling cavity is closed off by two cover plate halves. The

MONOTHERM® piston is used in passenger car and commercial

vehicle engines with peak cylinder pressures of up to 20 MPa.

1.1.2.4. Composite pistons

|

|

|

Fig.1.5: Optimized monobloc steel

piston

|

The composite piston enables the incorporation of cooling

cavities and the combination of the properties of various materials in one

piston. The performance range of four-stroke engines with composite pistons

extends from 500 to 30,000 kW, with up to 20 cylinders. Areas of application

include genets, main ship drives and auxiliary ship drives, and heavy

construction and railroad vehicles.

Here are many variants of composite pistons. Common to them

all is a design consisting of two main constituents: the piston crown with the

ring belt (upper part of piston) and the piston skirt with the piston pin boss

(piston skirt). The two parts are screwed together with appropriate threaded

fasteners

With two contact surfaces With one contact

surfaces

Fig. 1.6: Upper part of piston cooled by gallery (left) and

by orifice (right)

The upper part of the piston is made of forged steel, while

the piston skirt can be made from three distinct materials:

- Piston skirt made of forged aluminium-base

alloy, forged aluminium skirts, are suitable for low and medium peak

cylinder pressures, exhibit a low mass, and are easy to machine.

- Piston skirt made of nodular cast iron, Key

features of a composite piston with nodular cast iron piston skirt, Figure 1.6,

are low cold piston clearance and the resulting low secondary piston motion as

well as high seizure resistance.

10

Chapter 1: Overview on engine's piston

The casting process, in contrast to forged steel, allows for

undercuts and therefore a lighter design Superior to 200 bar. Compared with

pistons with aluminum skirts, however, the mass is increased as a result of the

higher material density.

- Piston skirt made of forged steel provides

ultrahigh component strength and, related to the process, a material with

extremely few defects. They are suitable for ultrahigh stresses greater than 24

MPa. Similar to pistons with nodular cast iron piston skirts, they provide the

advantage of low cold piston clearance, resulting in low secondary piston

motion.

1.2. Different forms of wear

Metal surfaces which are subjected to solid or fluid friction

in the presence or absence of a lubricant may be affected by wear patterns

which may range from regular, controllable wear (normal wear) to sudden

deterioration causing the failure of the mechanism.

Surface deterioration is an isolated or simultaneous

phenomenon classified into four basic forms: adhesive, abrasive, corrosive and

fatigue.

1.2.1. Adhesive wear

Adhesive wear or wear by metal - metal contact is the most

basic form of deterioration of surfaces. It is due to shear failure, during

friction, micro-welds or junctions formed instantaneously between the opposing

asperities of the two surfaces, in dry friction mode or in limited or mixed

lubrication. The formation of these welds, which is very localized, is favoured

by the thermal energy dissipated by friction, associated with very high contact

pressure.

According to its nature, the weld will be a true weld or "hot

weld", or a simple physical bond or "cold junction", therefore, depending on

the shear strength of the junction, shear breakage occurs inside the softest

metal or, on the contrary, at the junction.

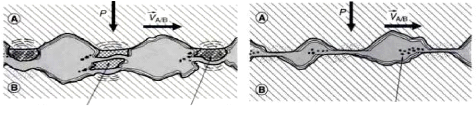

The deterioration thus takes all forms ranging from severe

scratching to light scratching or soft adhesive wear (Figure 1.8.).

In the first case, the deterioration, in its most serious form

which is the seizure of the surface (Figure 1.7.), is characterized by metal

stripping, transfer of metal from the softest surface to the hardest surface,

(Burning) and the emission of relatively large dimensions (some ìm to

some hundred ìm) of metal wear particles.

Fig .1.7: Piston seizure

11

Chapter 1: Overview on engine's piston

In the second case, the wear rate is very low and the wear

particles consist of very small fragments of metallic oxides of generally

lamellar shape (a typical dimension of the order of one to a few hundredths of

a im).

A The shear strength of the welds TS is

B The shear strength of the junctions

greater than the shear strength of the TS is less than the shear

strength of the

softest metal TB softest metal TB

Wear particules Transferred fragments

Wear particules

|

The shear occurs inside the softest body B, an adhesive

transfer and severe wear.

? Large wear particles, a few im diameters

? Important friction called "internal" or by

welding

|

The shearing occurs at the junctions wear is moderate (soft

adhesive wear)

? Very small wear particles (oxides) about 10 nm diameters

? Low friction known as "external" or by shear

|

Fig.1.8: Mechanisms of adhesive wear: A) severe adhesive

wear - B) soft adhesive wear

In engines, adhesive wear mainly affects the components that come

into contact with each other, such as cylinder and cylinder piston.

The introduction of antifriction additives which act chemically

when the temperature of the contact rises, by attacking the metal in order to

convert it superficially into a self-lubricating, easily shearable film,

generally consisting of metal sulphides and phosphates.

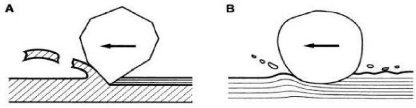

1.2.2. Abrasive wear

Abrasion is a deterioration involving two phenomena

- A material removal from the surface by cutting;

- Plastic deformation of the surface (plowing) without ablation

of material.

Fig. 1.9: Abrasion mechanisms: A) abrasion by cutting - B)

abrasion by plastic deformation

Chapter 1: Overview on engine's piston

The abraded surface thus loses metal in the form of micro

chips and is deeply modified by plastic deformation.

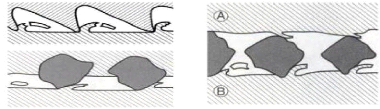

There are two types of abrasion:

- The two bodies abrasion caused by hard asperities or hard

particles embedded on one of the surfaces and wears the other surface;

Two bodies HVA > HVB

Hard asperities or particles Three bodies

embedded on 1 of the 2 surfaces

and wears the other surface Abrasive grains conveyed

between the

two rubbing surfaces.

Fig.1.10: The types of abrasive wear

12

- The three bodies abrasion generated by free abrasive

particles (3rd bodies) conveyed between the friction surfaces, if the size of

these particles is equal to the thickness of the oil film, the abrasion is said

to be normal, it is manifested by scratches having the appearance of cutting

grooves. On the other hand, if the abrasive particles are very small, the

deterioration, whose size and appearance strongly depend on the angle of

incidence of the particles with respect to the surface, is called abrasive

erosion.

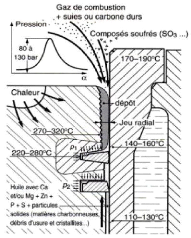

Fig.1.11. Diesel piston head deposit formation

Abrasive wear is countered by hardening of surfaces and

especially by efficient filtration of air (in engines) and oil.

Polishing wear of the cylinders of heavily loaded diesel

engines is a particular form of abrasive wear. The disappearance of the

machining lines by polishing the cylinder bore is due to the combined abrasive

actions of the carbon deposited on the piston crown (2-body abrasion) and the

solid particles carried by the oil (These deposits and sediments contain, in

greater or lesser quantity, microcrystals having a diameter of (0.1 to 0.5

ìm) of mineral salt, some of which are abrasive, resulting from the

interaction of the products of thermal degradation of the organometallic

additives of the oil.

13

Chapter 1: Overview on engine's piston

1.2.3. Corrosive wear

Corrosive wear is the friction removal of the reaction product

formed on the surfaces by chemical attack. Among these, we can site:

- Hydrochloric (HCl) and hydrobromic (HBr) acids, which

originate from the combustion of ethylene halides contained in the anti-knock

additive of leaded gasolines;

- Sulfuric acid (H2SO4), which comes from the cold

condensation of sulfuric anhydride (SO3) with the fuel combustion water in

engines operating with sulfur fuel, which is particularly the case for diesel

fuels.

- The organic acids coming from the partial oxidation of the

oil or the fuel, the shortest in length of organic chain are the most

corrosive. Corrosion is of particular concern when water and acids can condense

on metal surfaces, i.e. when the temperature of these walls is relatively low,

for corrosion to occur several conditions must be met:

- A corrodible metal (steel or antifriction alloy);

- A corrosive medium (aqueous electrolyte with a pH

sufficiently low to corrode the steel); - An intimate contact.

The corrosion can be eliminated by one of the following

methods:

- Elimination of sensitive metal (choice of a non-corrodible

alloy or an organic material);

- Placing a barrier between the metal and the medium;

In general, the first means of action is only rarely economically

or technically acceptable in the case

of internal combustion engines.

The second mean of action is specific to anti-rust and

anti-corrosion additives.

But the most useful way of protection is the coating (for more

information see the literature

review).

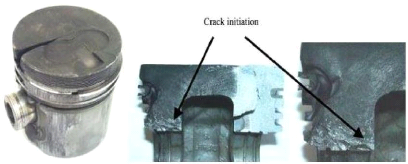

1.2.4. Fatigue wear

1.2.4.1. Fatigue fracture mechanism

By mechanical fatigue it is meant that the piston is subjected

to external variable loading. The resulting stress causes cracks to nucleate

and propagate in critical stressed areas. As shown in Fig 1.12, there are

mainly two stress critical areas where crack initiates: piston pin holes and

those regions on both sides of the bowl rim areas which are located on the same

vertical plane that contains the pin holes. It is also observed that there is

only one visible crack for mechanical fatigue.

Fig.1.12: Gasoline engine piston with a crack from one side

of the pin hole to the head

14

Chapter 1: Overview on engine's piston

Under thermal fatigue, thermal gradients develop stress in two

ways. Thermal stresses due to the distribution of the temperature along the

vertical axis of piston - high temperatures at the top and lower temperatures

at the bottom - and that due to the different temperatures on the piston head

due to the flow of the hot air or fuel impingement. In the first case several

fatigue radial cracks over the whole piston head can be observed.

The cracks so formed gradually grow under the fatigue

conditions until it develops into a fracture on the crown. If severe enough,

fracture continues across the crown surface to have the piston sliced to

parts.

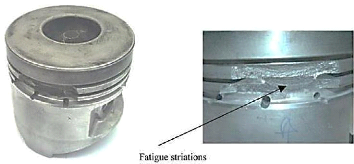

1.2.4.2. Fatigue damages to piston

Apart from piston crown, fatigue cracks are developed in other

parts of piston as well and it includes piston rings and piston skirt.

- Piston ring

As the wear on cylinder walls increases, clearance between the

piston and cylinder wall becomes high. Eventually, pressure acting on the ring

increases (because the ring comes out of the groove) and consequently stress

increase on the groove. The stresses at those fillet portions in the ring

groove seem to be sufficient to initiate fatigue cracks on the piston.

Fig .1.13: Engine piston with damaged grooves

In case the rings are not fitted correctly in the grooves, the

resulting misalignment stresses the ring material by the continuous

reciprocating motion. This will accelerates the fatigue crack propagation which

in turn stresses the ring lands and cause material to fracture away from the

ring land areas, as depicted in Figure 1.13.

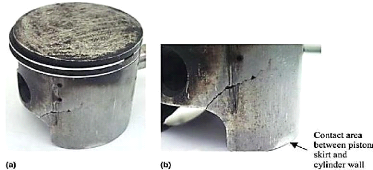

- Skirt fracture

If the clearance between piston and cylinder becomes too

large, piston will be misaligned with cylinder, i.e., piston will be always at

an angle with the cylinder walls. This causes the piston to flutter within the

bore during the engine running. With larger clearances, the piston rotation

angle also increases and makes contact with cylinder walls at two points; the

bottom part of the skirt and the top part of the piston head. These contacts

introduce a flexural load on the piston skirt. The

15

Chapter 1: Overview on engine's piston

consequence will be the formation of stress concentration

areas where cracks initiate and propagate onto fracture, as shown in Figure

1.14.

Fig .1.14: Initiation and propagation of cracks onto

fracture

1.3. Piston-cylinder Lubrication

1.3.1. The lubrication regimes in the piston-cylinder

couple

Based on studies made by several researchers, it can be confirmed

that:

- The main piston-cylinder lubrication regime is the hydrodynamic

regime;

-boundary Lubrication and sometimes dry contact occur in the PMB

and PMH areas, according to:

1. Courtney, Pratt, Tudor [PAN85] Using the measurement of

the contact resistance of the segments-cylinder;

2. Wing and Sauders [PAN85] from the study of the rapid

variations of the oil film thickness by adopting an indirect measurement of the

piston-cylinder diametral clearances;

3. Furuhama in 1959 [FUR59] after he noticed the

insufficiency of the hydrostatic lubrication which cannot explain a limit

lubrication of the segments with the TDC which possess in this position a zero

speed and consequently a zero film thickness;

4. Brown and Hamilton in 1975 [BRO76] by measuring the

pressure distribution in the oil film and the thickness of the film in the

vicinity of the TDC by capacitive proximity sensors. They demonstrated the

limiting lubrication of the segments in the vicinity of TDC and BDC

5. Allen and al in 1978 [ALL84] From the measured values of

the thickness of the oil film in the vicinity of the TDC, less than 0.25

ìm, they assert the existence of a metal / metal contact in these

zones.

6. Richez and al [RIC82] carry out tests on an engine and

show that the friction increases with temperature or with the decrease in

viscosity. The measurement of the amplitudes of the roughnesses (2 to 4

ìm) and the thicknesses of the oil film (0.5 to 10 ìm) enabled

them to demonstrate the existence of a metal / metal contact zone in the

vicinity of the TDC.

16

Chapter 1: Overview on engine's piston

7. Uras and Patterson [URA87] Measuring the friction force of

the piston and the measured friction force decreases as the piston velocity

increases. This frictional force also becomes important in the vicinity of the

TDC and BDC, indicating that the friction becomes limited in these regions.

8. Myers and al in 1990 [MYE90] Install capacitive gauges and

surface thermocouples to study the influence of different parameters on the oil

film in the vicinity of the TDC. They study the friction at engine start-up and

thus notice the breakage of the oil film which causes the metal / metal

contact.

- The boundary lubrication is located in the expansion and

compression cycles:

1. Rogowski in 1961 [ROG61] after measuring the

piston-cylinder friction force by means of a special device. He noticed that

this force becomes important during the compression and relaxation phase;

2. Furuhama and al in 1978 [FUR59] with the improvement of

their experimental set-up enabled them to show that the measured frictional

forces are very high in the second half of the compression phase and the first

half of the expansion phase at the TDC. The considerable increase in the

friction force confirmed the existence of a metal / metal contact between the

segment and the cylinder in these zones.

1.3.2. The main lubrication regime formulations in the

piston-cylinder couple 1.3.2.1. Formulation of Furuhama and

al

Experiments by Furuhama [RAY74] on driven engines and in

normal operation led him to state that the main mode of lubrication of the

piston and cylinder is of the hydrodynamic type. The Reynolds equation under

these conditions is written:

???? (h3

?? ?? · ????

????) = 6 · ???? · ??h ???? + 12 ??h

????

with h: oil film thickness, ?? :

Dynamic viscosity of lubricant, ??: Average hydrodynamic pressure, ????:

Speed of the piston.

The resolution of this equation makes it possible to determine

the pressure and velocity

distributions in the oil film.

1.3.2.2. Formulation of Richez and

al

Richez and al [RIC82] Introduce mixed lubrication of the segments

and take account of the surface

roughness. By noting that the heights of surface's roughness of

the segments and of the cylinder are

of the order of 2 to 4 ìm and that the thickness h of the

oil film is of the order of 0.5 to 10 ìm, they

define a factor ë= h /??, and proposed the criterion:

?? = 1 The lubrication is mixed;

?? = 1 The lubrication is hydrodynamic.

They also give the law of distribution of pressure and speed in

the oil film:

?? h3 ???? + ??h

???? (???? 12 ?? · ????

????) = ???2 ? · ??h ????

17

Chapter 1: Overview on engine's piston

???? = 1 - 0.9 exp (- 0.56 h

?? )

1.3.3. Generality on anti-wear additives (AW) in boundary

regime 1.3.3.1. Boundary regime and tribofilm

Lubricating oil consists of one or more base oil which

represents the framework of the product. However, for certain applications, and

particularly at high temperatures and pressure (as in the case of pistons), the

base oil is no longer efficient. In order to meet the various uses, multiple

and different additives are added, specific to each use. Among the main types

of additives are anticorrosive, anti-oxidation and anti-wear (AW) dispersant

additives. These additives influence the behaviour of the lubricant by

reinforcing its properties or by adding it others of which it is devoid;

Researchers in the field of lubrication develop different

laboratory tests and each test fulfils a given function. These tests are

Interesting on the mode of application or the behaviour of the lubricant. The

formulation of lubricants requires control of the functioning of each additive

(its reactivity to the metal surface and its mode of action) and their impact

on the environment [TAN07].

In order to improve the performance of the lubricants in

boundary regime in order to avoid seizure and to have reasonable friction,

additives and in particular anti-wear additives (AW) and extreme pressures (EP)

are incorporated in them. These compounds act directly on the metal surface by

forming a protective film on surfaces called tribofilm by chemical reaction or

physical adsorption.

Tribofilms formed in the boundary lubrication regime are

designed to reduce friction and to protect the surface from wear due to

lubricant/surface chemical reactions induced by temperature and pressure

conditions.

Boundary lubrication is a complex phenomenon in which several

parameters intervene such as solid-lubricant interactions, metallurgy,

roughness, corrosion, temperature, pressure and kinetics of chemical

reactions.

In the limit lubricating regime, the height of the surface

roughness becomes greater than the thickness of the film at the interface, the

oxide layer which protects the surface is removed and the two surfaces are

brought into contact. This situation causes wear, increases friction and can

cause welding of the roughness. The viscosity of the oil no longer intervenes

under these extreme conditions, it is the additives present in the oil which

will interact chemically with the metal surfaces to form the tribofilm whose

thickness is a few tens of nm and which protects the Parts against wear

[GEO79].

The additives (AW) by forming their own sacrificial film

replace the oxide protective layer and considerably reduce the wear rate.

1.3.2.2. Types of anti-wear additives

(AW)

The additives (AW) are classified according to their

reactivity with respect to the metallic surface in two types, the active

additives and the non-active ones [PAP98]. The active additives are those which

chemically react with the metal surface to form a film. On the other hand, the

non-active additives form films which are mainly unreacted with the surface.

18

Chapter 1: Overview on engine's piston

Molecules that contain sulfur, phosphorus and halides are

considered active compounds while molecules containing boron, aluminum and

graphite are classified as non-active compounds [DON94].

Table 3.1 shows the main anti-wear additives (AW) used in

lubrication.

|

Additive Families

|

|

sulfuric additives

|

dialkyldithiophosphates of zinc ZnDTP

|

|

2-benzothioyle-tert-nonyle disulfur

|

|

Phenyle sulfur

|

|

Benzyle mercaptan

|

|

Octadecyle mercaptan

|

|

Dodecylebenzylemercaptan

|

|

Ditert-octylemercaptan

|

|

Phosphoric

additives

|

Alkyl d'acide phosphoré

|

|

Alkyl phosphoré

|

|

Phosphites

|

|

Borate

Additifs

|

Esters boratés

|

|

Borates de potassium

|

|

Borates de calcium

|

|

mixed Additifs

|

Dithiophosphates métalliques (Zn,Co,Ni,..)

|

Table 3.1.The main anti-wear additives (AW) used in

lubrication

The universally used additives (AW) are

dialkyldithiophosphates and zinc (ZnDTP). This success is mainly due to its

good antioxidant and anti-wear properties and its low cost [TAN07].

Several authors have shown that the chemical structure of

sulfur-containing additives affects tribological performance, for example.

Disulfides have been shown to perform better in anti-wear AW than monosulfides

due to weak S-S bond in disulfides which is Easier to break than the C-S bond

in monosulfides [FOR70].

Croszek [GRO71] Considers that the anti-wear (AW) activity of

the disulfides depends on the electronegativity between the chemical elements

of this molecule.

19

Chapter 1: Overview on engine's piston

Sakuraia Has shown that oxygen in oil plays an important role

in the formation of oxide films and appears to have a good influence on

tribological behavior [FEN61]. From the chemical reactivity of some additives,

he concluded that oxygen and oxide films prevent wear on surfaces and reduce

friction.

Wheeler [WHE78] differentiates two types of wear: soft wear

and severe wear. Under severe pressure and temperature conditions, a

significant amount of iron sulfide is detected in the wear traces in comparison

with the mild pressure and temperature conditions, and concluded that under the

effect of the elevation of Temperature and pressure, the sulfur compounds react

by chemical corrosion with the metal surface to form iron sulfide.

Temperature affects the tribological behavior of sulfur

additives and the formation of tribofilms. Temperature seems to have a limited

effect on the decomposition of sulfur additives by promoting the formation of

iron sulfide films which improves tribological performance [TAN07].

Chapter 2

Aluminum and its alloys

22

Chapter 2: Aluminum and its alloys

2.1. Properties of non-alloyed aluminum (1000

series)

There are many grades of unalloyed aluminum, known

commercially as pure aluminum. These standard grades are part of the 1000

series of AFNOR standards. The purity of aluminum is always greater than 99.00%

(grades 1100 and 1200), very often higher than 99.40% (grade 1040), but can

reach 99.80% (grade 1080) or even 99.90% (grade 1090).

It is also possible to obtain a high purity aluminum of 99.95

% (grade 1095), 99.98 % (grade 1098), 99.99 % (grade 1199), and even an

aluminum of very high purity (greater than 99.996%, or even equal to

99.999%).

The structure of the pure aluminum is face-centered cubic at

any temperature below its melting point (660 °C). The main physicochemical

properties of unalloyed aluminum are given in Table 2.1: (At 20 °C for a

pure aluminum of 99.996%):

|

Melting temperature G??

|

660°C

|

|

Crystal structure

|

CFC

|

|

Density ??

|

2700 Kg/??3

|

|

Thermal conductivity ??

|

237 ????-1k-1

|

|

Coefficient of linear expansion ??

|

23.1x 10-6 k-1

|

|

Electrical resistivity ????

|

0.0265 ??????

|

Table 2.1: Physicochemical properties of unalloyed

aluminum

These properties are the reason why the unalloyed aluminum is

widely used (in developed countries more than 40% of the aluminum consumption

takes place in this state).

Table 2.2 gives the main mechanical properties of unalloyed

aluminum:

|

Ultimate tensile strength ????

|

40 à 50 MPa

|

|

Yield strength Re

|

10 à 20 MPa

|

|

Proof stress Re0.2

|

20 à 35 MPa

|

|

Young's Modulus E

|

63 à 71 GPa

|

|

Elongation to rupture A%

|

50 à 70%

|

|

Poisson's ratio õ

|

0.33 à 0.35

|

Table 2.2: Mechanical properties of unalloyed

aluminum

2.2. Aluminum alloys

The main alloying elements introduced into aluminum are

copper, manganese, magnesium, silicon, zinc and lithium. These elements can be

added individually or in combination. On the opposite, certain other elements

are more or less excluded, in order to improve a particular property. For

example the tenacity of alloys with magnesium and silicon is greatly improved

by additions of manganese and chromium with limited contents (often Cr <0.4%

and Mn <1%) and by a severe limitation of the contents of harmful elements

such as iron.

23

Chapter 2: Aluminum and its alloys

2.2.1. Classes of aluminum alloys

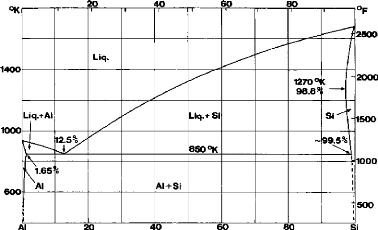

The aluminum alloys are classified according to the main alloying

element (s). We can

distinguish:

- Aluminum/copper alloys of the 2000 series;

- Aluminum/manganese alloys of the 3000 series;

- Aluminum/silicon alloys of the 4000 series;

- Aluminum/magnesium alloys of the 5000 series;

- Aluminum /magnesium/silicon alloys of the 6000 series;

- Aluminum/zinc alloys of the 7000 series;

- Aluminum alloys and other elements of the 8000 series.

We can also distinguish:

- Peening alloys (not hardening by heat treatment): which are

aluminum/manganese alloys and

aluminum/magnesium alloys;

- Heat treatment hardening alloys: which are aluminum/copper

alloys, aluminum/magnesium

alloys, aluminum/silicon alloys and aluminum/zinc alloys.

2.2.2. Physical properties of aluminum alloys

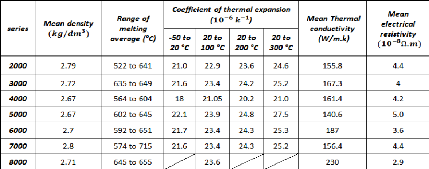

Table 2.3 gives the main physical properties of the different

series of aluminum alloys (the mean value of different experimental results are

considered):

Table 2.3: Physical properties of the different series of

aluminum alloys

2.2.3. Mechanical properties of aluminum

alloys

It is well accepted that the properties of aluminum alloys are

determined essentially by the microstructure of the alloys obtained.

The microstructure is essentially conditioned by the nature,

the quantity and especially the distribution of the elements of addition. Most

metallic elements can be alloyed with aluminum, but only a limited number of

those elements are used as the main addition and condition the properties of

the alloys.

24

Chapter 2: Aluminum and its alloys

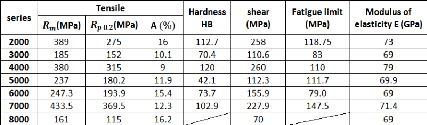

Table 2.4 below represents the mean values of the mechanical

properties for different series of aluminum:

Table 2.4: Principal mechanical properties of different

series of aluminum

2.2.3.1. Static strength

Table 2.4 gives the mechanical strength obtained for each of

the series of aluminum alloys. In fact, those characteristics can be varied

depending on many factors.

2.2.3.2. Tenacity

Three categories of aluminum alloy can be considered on the

tenacity point of view:

- Tenacity of low- and medium-strength alloys: those alloys are

of 1000, 3000, 5000 series and

all of other series in the annealed state;

- Tenacity of alloys of the 6000 series: Al-Si-Mg alloys with

medium resistance of the 6000 series

are commonly used for working structures;

- Tenacity of high strength alloys: those alloys are of 2000 and

7000 series.

For the high strength alloys, it can be noted that:

- The tenacity increases when the yield point decreases.

- The newest alloys currently used for the construction of modern

structures of aircraft are

designed to offer a particularly high tenacity:

? The 7475 is the aluminum alloy which has the best tenacity;

? The alloys 7010, 7050, and 7150 offer the best compromise

between strength and

tenacity.

2.2.3.3. Endurance strength

The Wohler curves of aluminum alloys have the following

characteristics:

- There is no asymptote up to 108 cycles, so the

fatigue test must be kept running up to 108 cycles to determine the

fatigue limit;

- The ratio between the fatigue limit at 108 cycles

(in alternating stresses) and the tensile breaking limit is equal to:

- 0.35 to 0.45 for Peening alloys (1000, 3000 and 5000 series

alloys);

- 0.25 to 0.35 for heat treatment hardening alloys (2000, 6000

and 7000 series alloys); In general, this ratio decreases when the breaking

load increases. Different parameters can influence the rate of fatigue

cracking:

25

Chapter 2: Aluminum and its alloys

in

- The stress ratio R = Sm : the rate

of fatigue cracking increases when R increases;

- The medium: humid or salty aggressive medium

accelerates fatigue cracking;

- Overloads: during a fatigue test, if the stress

intensity factor is temporarily increased by a tensile overload, a significant

reduction in the rate of cracking is observed after suppression of the

overload.

2.2.3.4. Corrosion resistance

In practice, aluminum has an excellent corrosion

resistance, because of that it can often be used without coating. Adequately

chosen, aluminum alloys without coating can resist to freshwater, sea water,

and so many chemical products.

However, like the most common metals, corrosion damage

can occur in different forms, depending on the class of the aluminum alloy, its

metallurgical state, the exposure conditions, assembly and stressing

conditions.

The principal forms of corrosion that can be

encountered on aluminum alloys are:

- General corrosion or uniform

corrosion

The exposed aluminum instantly covers with an oxide

layer of 5 to 10 nm thick, and its corrosion resistance depends on the

stability of this oxide layer in the corrosive medium. General corrosion is

characterized by the uniform decrease of thickness over the entire metal

surface; the oxide layer is dissolved in a regular manner by the corrosive

agent.

In a natural, rural or marine atmosphere, the

corrosion rate of aluminum is extremely low, even insignificant, and does not

exceed 5 pm / year. In general, the general corrosion resistance of aluminum

depends on the pH of the corrosive medium, that corrosion cannot practically

occur in an acidic medium with pH <4 and in a basic medium with pH>

9.

In the most aggressive mediums such as marine mediums,

copper-containing alloys (2000 and 7000 series) require protection; On the

other hand, the alloys of the 3000, 5000 and 6000 series may have a corrosion

resistance at least equal to that of the non-alloyed aluminum.

- Pitting corrosion

Pitting corrosion is a much localized form of

corrosion, which appears by the formation of cavities or recesses on the

surface, in which the diameter and depth depend on the class of the alloy, the

corrosive medium and the exposure time.

The rate of deepening of the pits generally decreases

due to the formation of hydrated alumina which hinders considerably the

exchanges between the corrosive medium and the metal. Experiments show that the

rate of propagation of pits v is related to time t by a

relation of the type:

V= k

· t1/

3

All the aluminum alloys are sensitive to pitting

corrosion, the best results being obtained with a content of 1% of iron (it is

the case of alloys 8006, 8011 for example), likewise the presence of 0.1 to 0.2

% of copper improves the resistance for the penetration of pits (the case of

alloy 3003).

26

Chapter 2: Aluminum and its alloys

- Galvanic corrosion

When two different metals are in electrical contact in a

corrosive medium, they form a cell which produces current by consuming the most

electronegative metal which constitutes the anode. Aluminum is the most anodic

material compared to other metals (except zinc and magnesium). Aluminum will

therefore often be the victim of mixed assemblies.

In fact, the attack rate of aluminum depends on: the

difference of potential between the two metals present; on the electrical

resistance between the two metals and on the corrosive medium and more

particularly on its conductivity.

- Corrosion cracking or Intergranular corrosion

The intergranular corrosion encountered in various metals and

aluminum alloys is the corrosion that propagates in the metal by consuming only

the grain boundaries. This type of corrosion is due to the presence at the

grain boundaries of a continuous and anodic zone compared to the interior of

the grains.

For aluminum alloys, it mentioned that:

- Alloys of 1000, 3000, 4000 and 6000 series: are not sensitive

to intergranular corrosion;

- Alloys of the 5000 series: Al-Mg alloys with less than 3.5%

Mg are normally not susceptible to intergranular corrosion and Al-Mg alloys

with more than 3.5% Mg may be sensitive to intergranular corrosion especially

if the magnesium content is high;

- Alloys of the 2000 and 7000 series: have a good resistance

to the intergranular corrosion obtained by a quick quenching.

2.2.4. Standards defining aluminum alloys 2.2.4.1.

Wrought aluminum alloys

This family of aluminum alloys is the most widely used in

industry. It includes all commonly

rolled products.

The NF EN 573 standard defines two European systems for the

designation of these aluminum

alloys: the numerical system and the alphanumeric system.

The numerical system uses a 4-digit code which refers indirectly

to the chemical composition.

According to this system the designation of an alloy includes

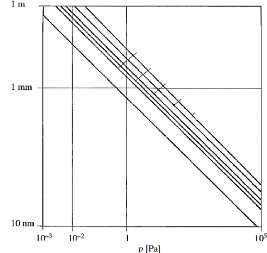

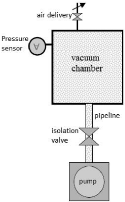

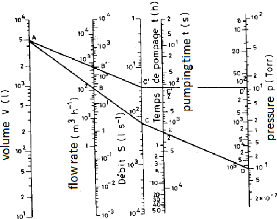

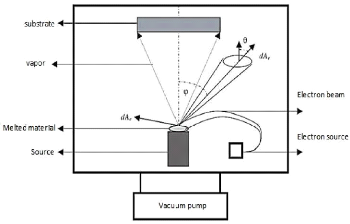

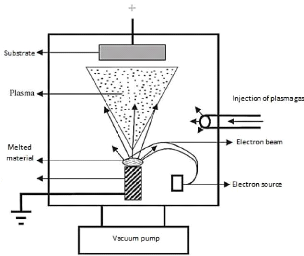

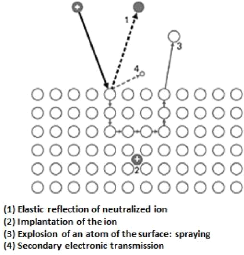

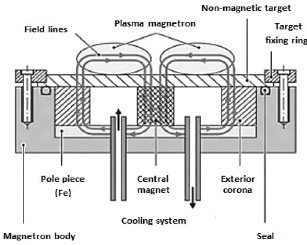

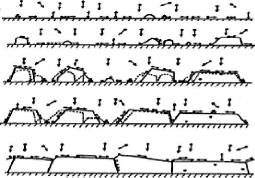

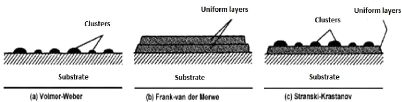

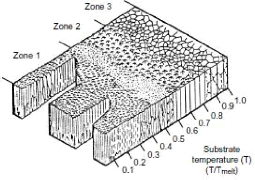

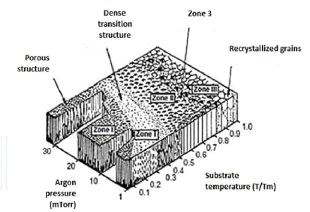

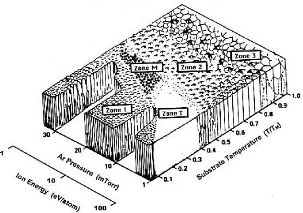

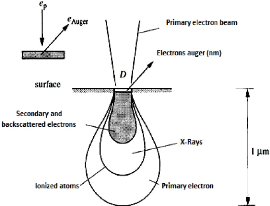

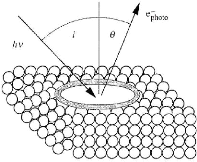

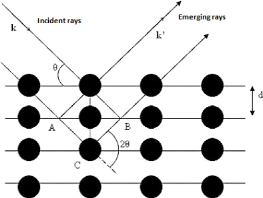

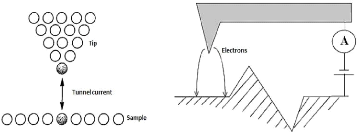

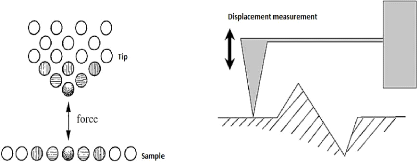

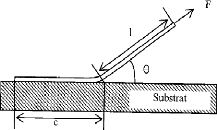

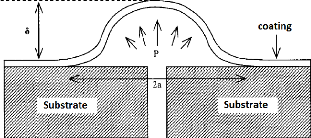

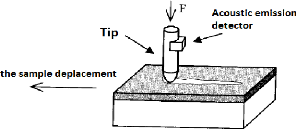

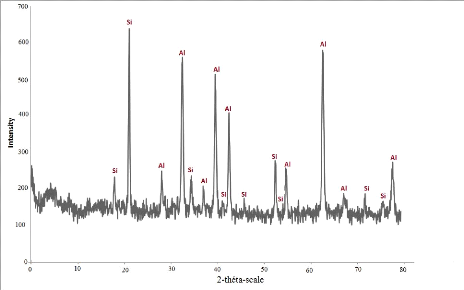

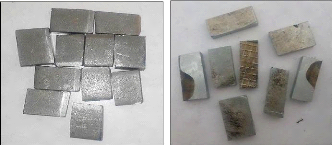

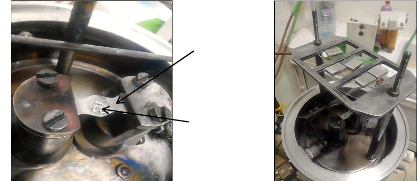

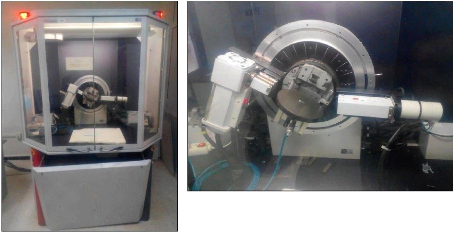

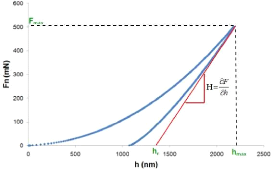

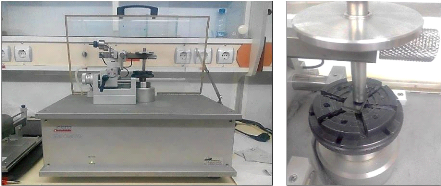

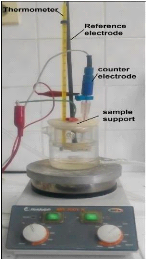

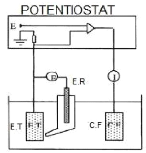

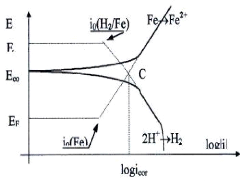

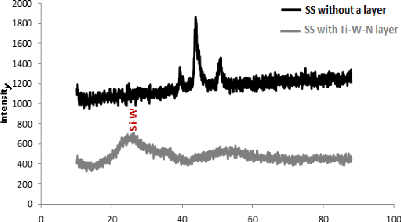

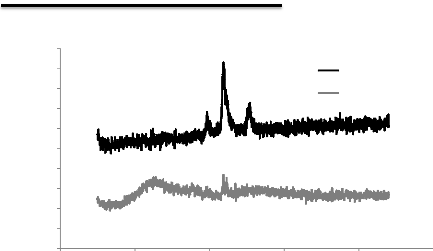

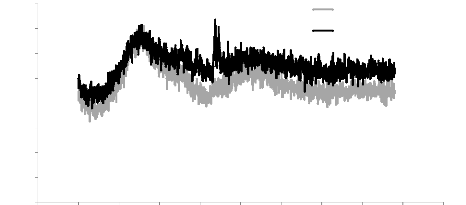

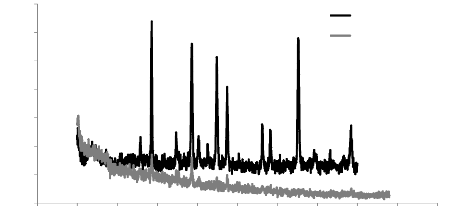

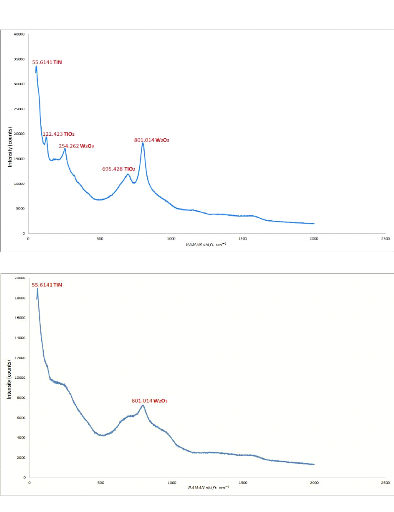

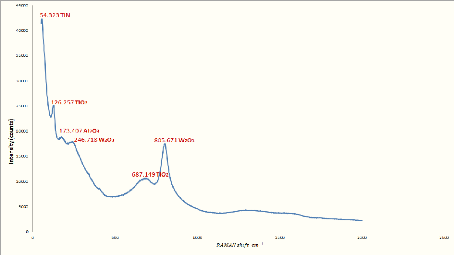

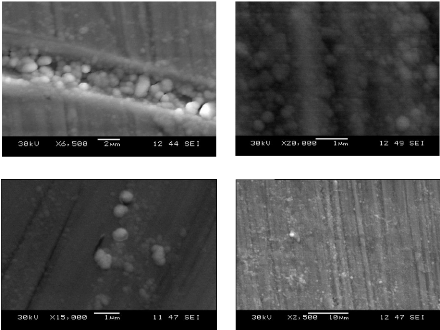

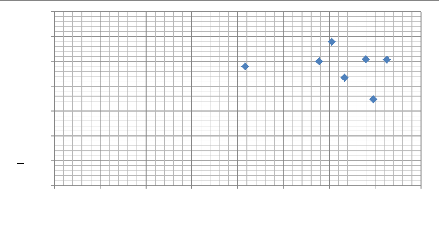

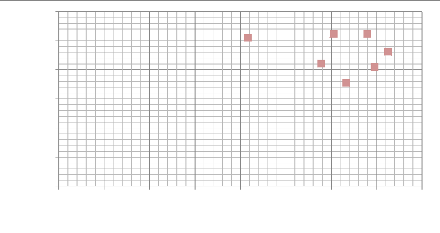

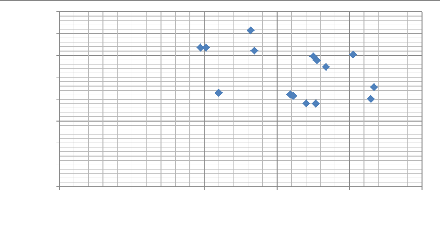

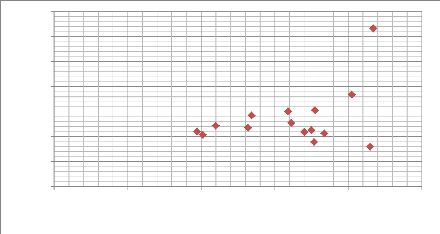

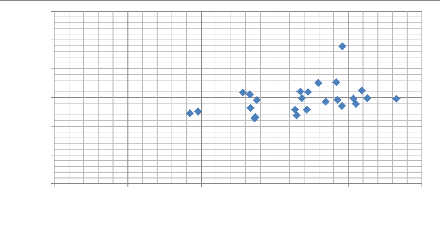

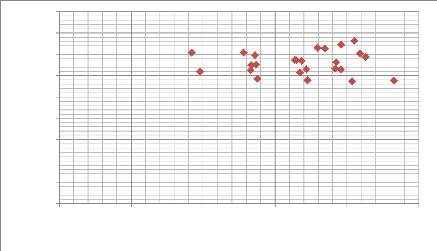

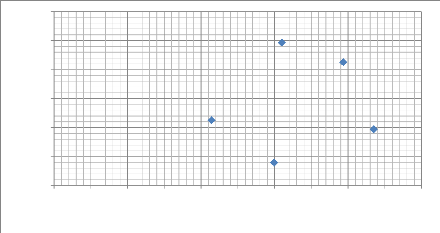

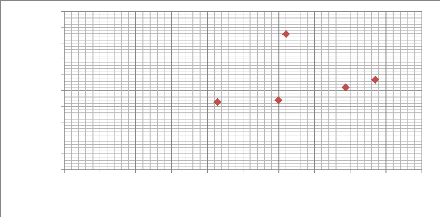

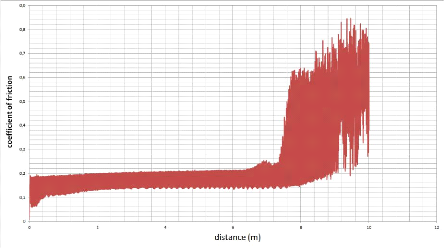

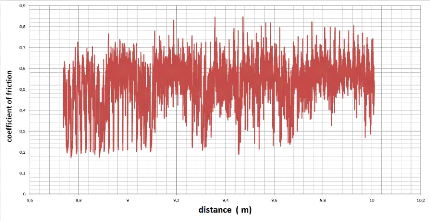

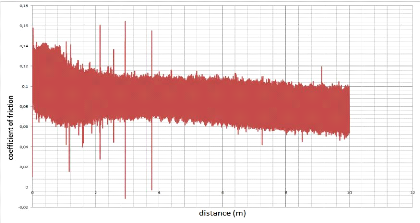

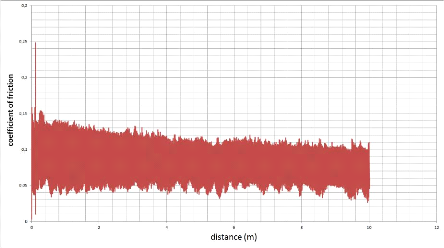

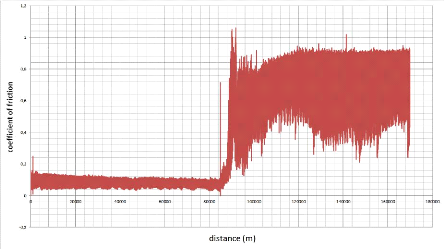

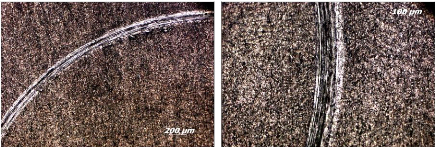

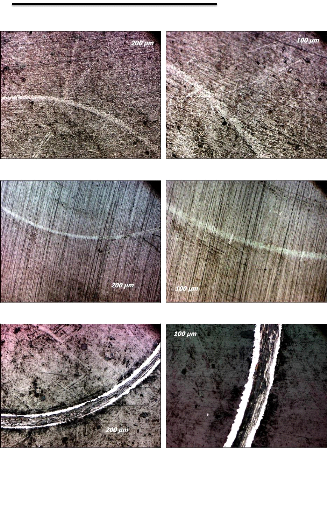

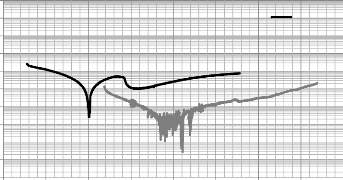

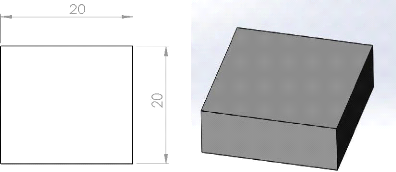

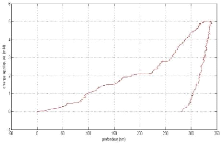

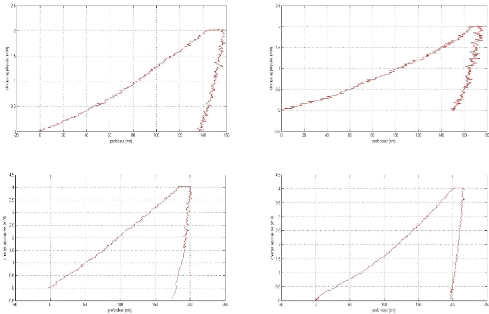

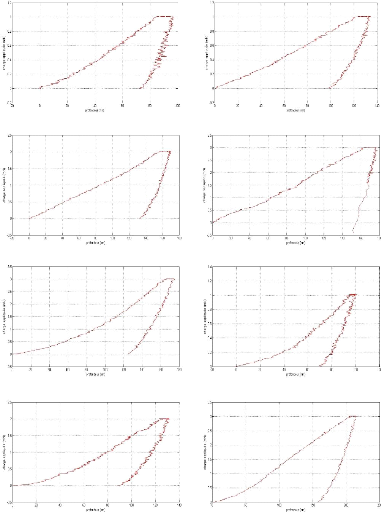

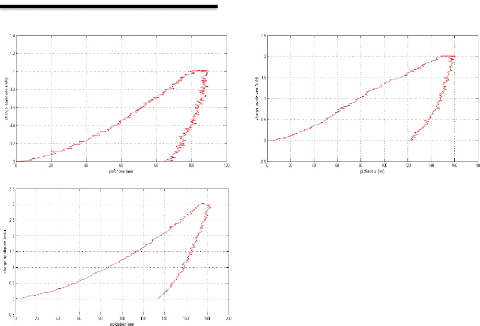

successively: