1.3.1.3.2.2: Softwares

Apart from some excel sheets used by the hydrology department

in the analysis of hydrological data and the SCADA software, the main software

used by the network operations department is operations and capacity planning

is the QSOM (Quantitative systems for Operations Management) software. It is

used in daily dispatching through unit commitment and the establishment of a

production plan.

1.3.2: The TSO and the new

electricity market system

The process to open-up the electricity markets system in

Cameroon as stated by the new electricity law started after the privatization

of SONEL on the 18 July 2008 by the American AES Corporation. AESS would soon

share the electricity market in Cameroon with Independent Power Producers

(IPP), Independent Transmission Companies (ITCs) and independent retailers

including large customers [2].

The TSO (Transmission System Operator) presently part of the

network operations department would be unbundled from AESS and assigned to a

subsidiary of AESS as stated in the concession agreement. AESS shall conserve

transmission assets, asset owner responsibilities and exclusive rights to

provide transmission services in the scope of transmission while the TSO shall

conserve exclusive right to managing operations on the transmission network.

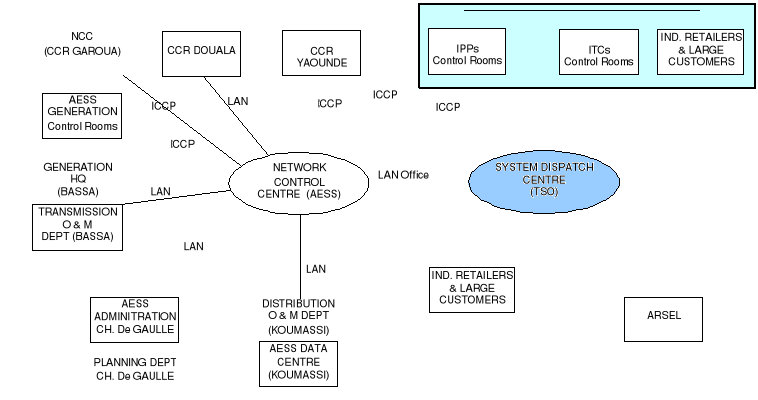

The TSO would be at the heart of this new electricity market

system as demonstrated in the future hierarchical dispatching structure

below

Figure 7: Future

hierarchical dispatching structure [3]

The TSO in this new electricity market structure has as

mission the following [23];

1. Maintain the security and the balance of load flows on the

Transmission system and undertake the management of network power flows, taking

account of exchanges within the interconnected network;

2. Maintain the reliability and security of the Transmission

system, taking account of constraints upon the latter, and implement such

measures as are required to ensure the availability of all the requisite

auxiliary services and the maintenance of a high level of reliability and

security on the electric system;

3. Ensure the optimum use of existing capacity;

4. Manage the take-up of available electricity production at

the lowest possible price, preferably from the national market in case of

exports, in accordance with functions in the general interest to be undertaken

by the Transmission System Operator;

5. Guarantee the availability of management data and ensure

that interested parties receive any information required for the purposes of

billing and the settlement of payments in respect of services provided;

6. Not practice any discrimination between system users,

subject to the limits of available capacity;

7. Supply to the operator of any other system which is

connected to the SONEL system sufficient information to allow the secure,

effective and coordinated operation of interconnected networks;

8. Facilitate the interconnection of systems under the terms

of agreements concluded with any other system operators, participate in the

implementation of rules governing interconnection and supervise compliance with

these rules;

9. Prepare and submit to the Agency an annual estimate of

Generating capacity, Transmission capacity and Distribution capacity connected

to the system; and

10. Identify requirements for interconnection with other

systems, potential Transmission capacity and electricity demand for the next

ten (10) years; this analysis will be updated and submitted to the Agency each

year.

In order to aid the TSO to properly execute its functions and

carry out its mission, AESS is about to put into operation a new PMS (Power

Management System) on the whole Cameroonian electricity transmission network

which also forms part of the context of this work and of which the TSO (more

specifically, the information system division under which i did my internship

and of whom this dissertation concerns) has as obligation under this context

Ø Project ownership responsibilities for the

implementation of the Power Management System (PMS) [23]

Ø Coordination of the proper operational integration of

the PMS in business processes within the AESS [23]

And of which the business integration of this PMS in line with

the PMS project opening memo is the last phase for the complete realisation of

these obligations.

1.3.3: Problem

statement

Based on the concession agreement signed between AES and the

Cameroonian government which requested [2]

1) Modernization of company equipments

2) Modernization of operations management

AESS is about to put into operation a new PMS for the

supervision, control and management of operations on the whole Cameroonian

electricity transmission network. Also in order to ensure security and

reliability in electricity network and market operations, this information

system and the information obtained would be shared between the TSO (system

operator, who has exclusive right to operations management) and AESS

(concession holder, who conserves asset owner responsibilities and has

exclusive rights to provide transmission services).

Faced with a business integration challenge which key to

correct implementation, complete technology transfer, proper operation and the

absolute ownership of this system; AESS has decided study and analyze all the

requirements and aspects for the business integration of this system in the bid

to design specifications and quality assurance measures for efficient business

integration.

In other words, it involves designing quality assurances

measures (requirements and specifications) used in the subsequent development

of a number of quality assurance checklists to ensure the efficient business

integration of this new PMS system. These quality assurance checklists to be

established subsequently would be used to demonstrate compliance with the

defined business integration requirement specifications upon completion of

business integration to ensure correct implementation; full, proper and

sustained operation; complete technology transfer and absolute ownership of

system.

1.3.4: PMS

description

The PMS is an IT-based solution package composed of SCADA

infrastructures on top of which specific softwares are implemented to manage

operations such as planning, supervisory control, energy accounting between the

main nodes of the network e.t.c. More specifically, it is an information system

with information management infrastructures/systems for real-time analysis of

information.

1.3.4.1: Compositional

overview

The new PMS system to be supplied by Siemens (EPC contractor)

and to be business integrated is made up of the following three subsystems with

their corresponding main operational objectives;

1. SCADA/EMS with main operational objective the optimization

of network monitoring and control as well as switching operations for a better

system security and reliability [2]

2. Water Resources Management System (WRMS) with main

operational objective the optimization of the water discharge from the storage

dams for an efficient energy generation and water use in the hydro power plants

[2]

3. Automatic Meter reading/Metering Management System/Energy

Data Management system (AMR/MMS/EDM) with main operational objectives the

provision of reliable metering data from any major grid node of the overall

system network to all entitled stakeholders and the determination of electrical

losses inside the electrical supply system of Cameroon [2].

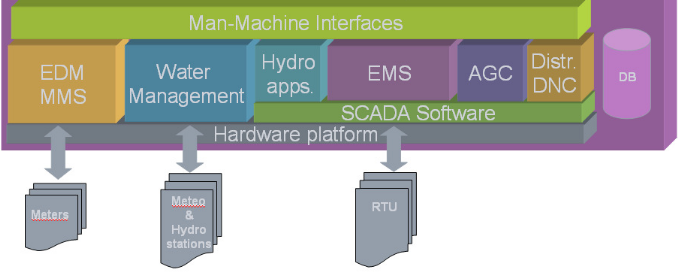

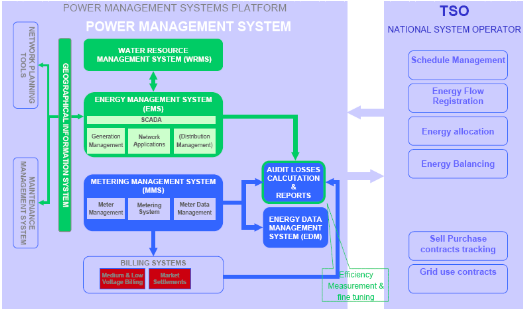

The compositional overview of the PMS is depicted in the

figure below where real time data/information from the substations and power

stations, the meteo and hydro stations and grid metering points acquired and

processed by their respective hardwares; RTUs/data concentrators,

meteorological/flow meters and grid connected meters; are transported over a

telecommunications network to an interface hardware platform (made up of

servers, switches, e.t.c) to be analyzed and processed by their respective

softwares (information management systems); SCADA/EMS, EDM/MMS and WRMS

softwares.

Figure 8: Compositional

overview of PMS system [5]

1.3.4.2: Technical Overview

of PMS

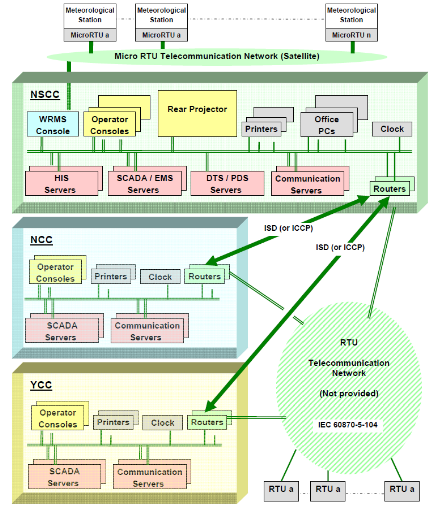

This IT-based solution package is made up of both hardware

(network and control) and software components. The major network and control

components of this PMS to be installed at the different substations, power

stations, hydro and meteo stations and at the system controls centres are

depicted in the figure below showing an overview of the PMS

Figure 9: SCADA/PMS

system Overview [5]

All the different data acquisition stations and system control

centers have communication buildings containing all the different

telecommunication equipments such as communication back-up power supplies e.g.

UPS, diesel generator, battery e.t.c; data concentrators; switches; routers and

the fiber optic nodes e.t.c. All sensors and data acquisition equipments at the

different data acquisition stations and grid metering points are connected

through a highly redundant communication network to system control centers for

information and operations management.

All RTUs communicate with the SCADA system through dedicated

data channels. They will have single and double pole statuses, analog and pulse

accumulator inputs, as well as supervisory control outputs for switching of

circuit breakers and isolators as well as raise/lower controls for tap-changing

transformers. These RTUs communicate in [1]

Ø IEC 60870-5-101 (balanced and unbalanced mode)

Ø IEC 60870-5-104 (which is TCP/IP and thus

routable)

Ø dual-port-communication either

o With homogenous protocols (IEC 101-101 / IEC 104-104)

o Or with mixed protocols (IEC 104 main channel / IEC 101

standby channel).

Ø With a future capability of communicating in the IEC

61850

Six different telecommunication systems make up the

telecommunication network associated to this new PMS system for voice and data

transmission and include [1]

Ø OHTL (Over-Head Transmission Line) Power Line Carrier

suitable for voice, SCADA data, corporate data and hotline telephones

Ø GSM fixed mobile facility at each substation

Ø Low Power VHF (Very High Frequency) link to remote

offices

Ø Satellite link to the Garoua office in the North

Ø Microwave link

Ø FOC (Fiber Optic Cable) laid in the way leave of the

existing OHTL's

At the system control centers, functions (information

management systems and their corresponding applications) are compartmentalized

into functional blocks/subsystems with the subsystems implemented on different

servers and the servers distributed along a redundant Local Area Network (LAN).

All the information managements systems (SCADA, EMS, WRMS, MMS and EDMS) and

their corresponding application are critical in operations management and are

hence implemented on dual redundant servers, with one of the servers serving as

a hot standby. All the servers, workstations and network equipments are

interconnected through a redundant fast Ethernet LAN using Ethernet switches.

The most important and fundamental hardware equipments found in all the system

control centers include [5]

§ Application and system servers, performing all the main

data processing tasks and acting as the information reference sources for the

entire system. Critical applications are implemented on dual redundant servers

with one of the servers functioning in the hot standby mode.

§ Multiple workstation consoles with about 3 VDU per

workstation. The workstation consoles are configured for different purposes

(Operator, Engineering, Maintenance, Training e.t.c).

§ Large wall display unit connected to the real-time LAN

to rear-project any displays that would ordinarily be visualized on a

workstation

§ Redundant fast Ethernet 10/100base T switches to

interconnect the different system control center equipments

§ GPS time and Frequency System (TFS)

§ Redundant color and Black & white printers

accessible from workstation consoles for printing of the operating status of

the network anytime an event occurs.

§ Redundant WAN routers for interconnection to other

control centers and RTUs

§ Firewalls for connection to other LAN and WAN such

corporate office LAN, TSO LAN, the internet

This new PMS as depicted in the figure above would be

implemented on three system control centers with the following borders of

operational responsibility [5]

1. A National System Control Center (NSCC) to control and

monitor the entire HV network of AES SONEL in Cameroon, including the outgoing

MV feeders, located in Douala and made up of SCADA and EMS applications.

2. A regional Northern Control Center (NCC) to control and

monitor (in case of break-down of data communication to Douala) the isolated HV

network of the North, including the outgoing MV feeders, located in Garoua and

made up of only SCADA applications.

3. A back-up Yaoundé regional Control Center (YCC) to

control and monitor (in case of break-down of data communication to Douala) the

Yaoundé HV network including the outgoing MV feeders located in

Yaoundé and made up of only SCADA applications.

Also, regional distribution grid monitoring and partial

control would be done at the system control centers and by the regional

distribution control centers (CCRs) in the future.

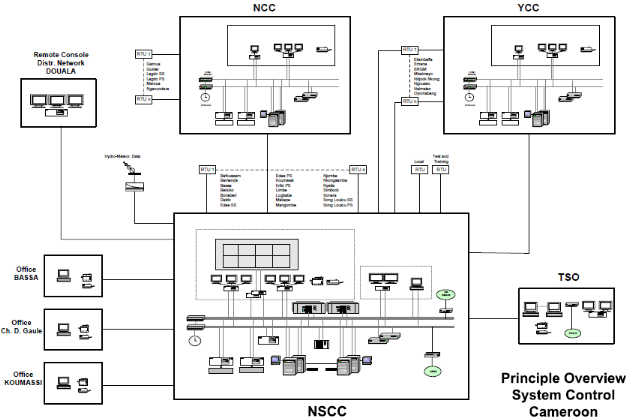

LAN connections shall be installed between the AESS offices in

Douala (Bassa, Charles de Gaulle and Koumassi), the system control centers and

the TSO offices for information sharing on transmission and distribution

planning and maintenance by AESS as well as on other issues such as energy

dispatch, hydro-thermal scheduling/coordination and water management by the TSO

as depicted in the figure below which shows an principle overview of the PMS

and the future hierarchical dispatching system.

Figure 10: Principle

overview of system control center, Cameroon [1]

Also as depicted in the figure above, there will be an

operator workstation with a three screen Console for each distribution network

((Yaoundé (YCC), Garoua (NCC) and Douala (Remote

console)). For the distribution grid of Douala one operator

workstation and corresponding Console will be located in the same building as

the SNCC. The subsystems (back-up Control Centers, YCC and NCC) for

Yaoundé and Garoua will be located at the AESS building in Mbankolo and

the control building of the Garoua SS/PS. From these workstations the MV

feeders in the corresponding HV/MV substations can be remotely controlled and

supervised.

1.3.4.3: Functional

Overview of PMS

Any time there is a change of state in the network as a result

of an event, signals (alarms, status, measurements and control signals) from

the sensors and actuators locally controlling the different substation and

power station equipments, stored and processed in the RTUs/Data concentrators,

are send over a redundant telecommunications network to the control centers and

then displayed in real time on the workstation consoles of the grid dispatch

operators. This real time data and displays give the operators minute-by-minute

up-to-date information about the status of the network and are also used by the

underlying EMS application modules for real time analysis and computations to

aid them in decision-making.

In addition to some of the supervision, control, data

acquisition, data processing and MMI functions provided by the existing SCADA

system and which would be renewed and extended by the SCADA subsystem of this

new PMS system, this new SCADA subsystem brings in new functionalities such as

[2]

· Topology processor: responsible for analyzing the

open/closed status of network switching devices such as breakers and

disconnectors in order to define the configuration of the network for screen

projection and display.

· Data dissemination: provides the ability to transmit

and receive data (telemetered data, calculated and manually entered data, data

generated by application programs and text data such as alarm messages, event

messages e.t.c to and from other control centers and other computer systems e.g

enterprise management systems or enterprise wide databases, settlement systems

e.t.c.

· Outage scheduler: assist authorized user in scheduling

future outages of power system equipment.

· Information storage and retrieval functions such as

journalizing, energy data collection and calculation, disturbance data for post

mortem review.

The figure below illustrates the different functional

blocks/subsystems of the new PMS and how they interact with each other. The EMS

subsystem has the main task of economically optimizing the utilization of

generation facilities within the constraints imposed by the transmission

network and power/energy exchange contracts or power producers and includes all

the task related to energy purchase, determination of generation cost,

generation maintenance schedules, unit commitment, load frequency control e.t.c

The Energy Management Software in the Power Applications refers to the group of

functions that monitors and controls the generated and exchanged power in the

electric system. In real-time the EMS there would be a significant amount of

coordination between the control center and the various power plant facilities.

System-wide economic benefits are to be achieved when this coordination would

be optimized taking into consideration unit efficiencies, fuel costs and

availability, transmission efficiencies, unit and transmission outages as well

as interchange power availability and price.

Figure 11: PMS

subsystems functions [2]

The following new functionalities amongst others would be

brought in by the new EMS subsystem in capacity and operations planning and

metering and scheduling [1];

· Load forecast: forecast on demand on daily, weekly,

monthly seasonally (rainy and dry season) and annually basis as well as use the

forecasting model predict initially stream flow between the reservoirs

(Mbakaou, Mape and Bamendjin) and the power plants (Edea and Songloulou).

· Economic dispatch: allocate generation in an optimal

manner among committed units to minimize production cost while respecting

reserve requirements and other constraints

· Load Frequency Control (LFC): to keep controlled area's

frequency, area interchange and system time within pre-defined limits.

· Interchange scheduler: allow the operator to develop

record and maintain the interchange transactions negotiated with other systems

and/or generating companies.

· Reserve monitor: to monitor and account for available

generation capacity and system reserves both system-wise and on a generating

unit basis as well as reactive power reserve to allow voltage control

regulation.

· Hydro scheduling: responsible for determining optimal

operation of the hydro system, taking into account constraints and limits.

· Hydro-thermal coordination

· Energy accounting: for calculating the cost of energy

interchanges based on tariffs defined in the respective transactions.

· Power flow: enable operator to study power flow under a

wide variety of different network situations

· Short circuit analysis: analyze potential short

circuits in network and compute fault currents at selected buses and fault

current contributions from other equipment near the faulted buses

· State estimator: application that processes raw

real-time telemetry data and pseudo measurements to provide real time power

flow solution for the entire network as well as detect and isolate failed or

bad data using either the orthogonal transformation algorithm or the normal

equation with constraint algorithm. Also checks and verifies credibility of

data including limits, consistencies and validity.

· Contingency analysis: application that analyses the

threats to the power network that can potentially result from a credible set of

contingent events under steady-state power system conditions e.g. short

circuit, line loss e.t.c using either the Newton-Raphson's or the fast

decoupled power flow algorithm.

· Optimal power flow: application that enables

optimization in the utilization of the power system generation and transmission

network by using a non-linear programming method to identify operating bottle

necks and the marginal cost of binding constraints in MW dispatch, MVAR

dispatch, fuel cost minimization and remedial scheduling.

· Dynamic stability simulation: solve power systems

dynamic problems such providing accurate simulation models and algorithms to

cover the complete range of transient and time frames, calculation of initial

conditions based on power flow results e.t.c

· Harmonic analysis: for carrying out frequency scan and

harmonic load flow for the determination of network natural frequencies and for

filter design.

· Dispatcher Training Simulator: A DTS (Dispatcher

Training Simulator) for both new and experienced dispatchers with main

functions to train new dispatchers, train dispatchers on advanced EMS

applications, train dispatchers on new EMS applications, testing new EMS

packages and post disturbance analysis.

Apart from the SCADA functions of data acquisition, monitoring

and control of hydro stations, the water management system offers the following

addition functionalities [1]

· Forecasting: water flow and water level forecast at the

different hydro stations on the Sanaga and benue rivers, stream flow between

the reservoirs (Mbakaou, Mape and Bamendjin) and the power plants (Edea and

Songloulou) and inflow into the reservoirs during the discharge and filling

periods using a forecasting model that uses measured historical data from hydro

stations and forecasted precipitated data

· Determine the optimal release of water from the

reservoirs to cover entire dry season taking into consideration the hydro plant

cascading on the river basin using a catchment model

· Scheduling of hydro and thermal plants to optmise

resources especially during critical periods such as the dry season

All energy flows into and out of the HV network and other

energy flows within the energy market would be processed by the MMS [1].

Metering data from all the metering points equipped with metering equipments

(modems/IEDs) would be send over a telecommunications network to the central

MMS. This MMS combined AMR system offers the following functionalities

· Data acquisition

· Data storage and processing

· Data validation

· Data reporting and analysis

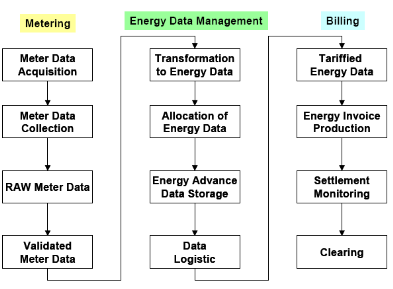

There is in general a gap between the physical energy flow, which

can be determined by the meters installed in the electrical grid and the energy

flow determined by the rules of the electricity market. The transformation from

meter data into energy data is a crucial function and a prerequisite for the

settlement of the market interactions between the entitled market participants.

The energy data management (EDM) is a software component that transforms

metering data into energy data by processing besides the metering data also the

schedules of the forecasted data for consumption and electricity provision [1].

The EDM system offers the following functionalities using some mathematical,

programmable macro and scheduling functions with an interface to contractual

and economic information [1]

· Transformation from metering data to energy data

· Depiction of commercial transactions

· Energy allocation

· Energy balancing

o identification of deviations between forecasted consumption

schedule and real consumption

o identification between forecasted supply schedule and real

supply schedule

o allocation of balance energy

· Verification of energy supply from various sources

The figure below depicts the flow of metering data from the

metering system through the energy data management system to the billing

system

Figure 12: Metering

Management system [1]

The figure above shows clearly the function of an EDM-system

in the context of metering and billing.

1.3.5: The Business

Integration problem

Business integration involves all the processes necessary in

bringing into full and sustained operation equipments (hard and soft) in order

to make sure that they satisfy the needs they were undertaken for during

buying. While the excellent business integration of a system can have

substantial impact on the success of a business, technology alone has no value.

In the case of information systems, business integration includes all the

processes from implementation through transfer and operation to ownership and

the excellent business integration of an information system is indispensable

for

Ø Correct implementation

Ø Complete technology transfer

Ø Full, proper and sustained operation

Ø Absolute ownership

The notion of business integration of an information system

brings in the following important concepts

1. Technology transfer/technology transfer project

management

2. Project implementation/information systems project

implementation

3. Process reengineering

4. Change management

The most successful business integration implementations are

those that meet the business integration requirements and contribute to the

overall success of the business. The successful business integration of an

information system by a business is measured with metrics reflecting the key

performance indicators of the business and not IT metrics.

The socio-technical infrastructure of AESS in the case of

information systems, is made up of obsolete technologies/equipments (hard and

soft), ideas, concepts and technical as well as scientific know-how. A good

example is the LS 2000 SCADA system installed since 1990 by `Landis and Gys'

being used up to today as the main system in supervision and control while

manufacturing of its equipments/components was discontinued since 1999 making

maintenance, upgrade and extension of the system extremely difficult. New

information system technologies/equipments destined for use in operations

management such as for supervision and control, operations planning have faced

serious business integration problems because of this technical, cultural and

conceptual resistance like in the case of the new SKAN4 SCADA system supplied

by Siemens with the aim of renewing and extending the capabilities of the LS

2000 SCADA system as a result of network expansion and increase in the number

of substations, which is not fully operated and has been partially abandoned;

the new daily dispatching software (QSOM) which faced resistance in application

by the dispatch operators e.t.c. This obsolete socio-technical infrastructure

and the concept of routine makes it extremely difficult for AESS to adapt and

change against the reception of new equipments/technology which would impact

the technological, functional and organization aspects of the company.

|