|

UNIVERSITE DE YAOUNDE I

ECOLE NATIONALE SUPERIEUREPOLYTECHNIQUE

DEPARTMENT OF ELECTRICAL AND

TELECOMMUNICATIONS ENGINEERING

REPUBLIQUE DU CAMEROUN

Paix - Travail - Patrie

THE UNIVERSITY OF YAOUNDE I

NATIONAL ADVANCED SCHOOL OF ENGINEERING

REPUBLIC OF CAMEROON Peace - Work -

Fatherland

ti

REQUIREMENT STUDY FOR THE BUSINESS INTEGRATION OF THE

NEW SCADA/EMS SYSTEM ON THE AES-SONEL NETWORK IN CAMEROON

Presented by

Mbelli Njah Fongha

In partial fulfilment of the requirements for the obtention of

a

«DIPLOME D'INGENIEUR DE

CONCEPTION»

In Electrical Engineering

: Pr. Thomas TAMO TATIETSE

In front of the jury composed of;

Examiners: Dr. Paul-Salomon NGOHE-EKAM

Engr. Edwin MBINKAR

Supervisors: Pr. Emmanuel TONYE

Dr. Patrick KALTJOB

Guest: Engr. Alain OYONO of AES

SONEL

2008-2009 Academic Year

Date: 29th OCTOBER 2009

President:

DEDICATION

TO MY CHAMPIONS MR AND MRS MBELLI NJAH, MBELLI NJAH NKWENTI,

MBELLI NJAH MAMBO-AMECK AND MBELLI NJAH NDANGOH-CHI

ACKNOWLEDGEMENTS

To GOD ALMIGHTY, for the privilege and

opportunity He granted to me to be in and go through this prestigious

engineering institution. All glory and honor be ascribed to His name for His

grace, compassion, strength, wonderful blessings and special favor during my

internship at AES-SONEL

Many thanks to all those who contributed morally,

academically, spiritually, financially, socially, and professionally to making

me a 21st century Polytechnician Engineer:

Pr. Awono ONANA, Director the National Advanced School of

Engineering for admitting me amongst the best 100 students during the

competitive entrance into this prestigious institution in September 2004

Pr. Thomas TAMO TATIESE, Vice Director and Dean of Studies of

Polytechnic, Yaoundé, for his academic contribution to moulding as a

21st century Polytechnician Engineer

Pr. Emmanuel TONYE and Dr. Patrick KALTJOB, for accepting to

supervise and work with me and for their understanding during periods of

uncertainty

Dr. P.S.Ngohe-Ekam, Eng Moses TABE, Eng Edwin MBINKAR and

Mr. Mouna, for all their moral support and motivation during my snag times in

school

The teaching and auxiliary staff of the National Advanced

School of Engineering Yaoundé for the support and knowledge made

available to me by them.

ASPY (Association of Anglophones of Polytechnic

Yaoundé), for always standing beside me during my times of success and

failures as a student in Polytechnic, Yaoundé and also for their support

given by to all the other Anglophones of the school

All my class mates especially NDIFOR CYRIL FRU, FONKWE

FONGANG EDWIN, MBANTAPAH PASCAL LOHKOH, TITUS TANWIE TALLA, ESSOUA FRANCK

CYRILLE, TCHOUMWHI NOUMBA WILLIAM and DAH ELVIS; for their wonderful support

especially in times of difficulties

Pr. Beban Sammy CHUMBOW for his fatherly love and support

during my training in school.

The CHUMBOW's family, for their support during my life as a

Student Engineer at Polytechnic, Yaoundé

All the Njah's family especially Aunti Stella, Aunti Angeline

and Aunti Comfort Chumbow for always being ready to help me in times of need

All my aunts, uncles and cousins who have made sacrifices to

help see this day

All ASPY Alumni especially Ashu Besong Nso, Fon Immanuel

Umenei, Ebot Daniel and Motuba Rosa for their financial support and motivation

during my internship and my life as a student engineer of polytechnic,

Yaoundé

All family friends especially at home and abroad

All senior friends especially Mrs. NYEMB ELISE for all her

support during the difficult times of my life as a Student Engineer

All my friends at home and abroad especially TABIAYUK

AYUKOTABE and BESONG ERIC AYUK for always standing beside me

All my petits especially ABONGMO SIMON-PETER, TANKU CONRAD

AND COLEMAN for always reminding of my function as a senior brother and the

responsibility to show them the way

All other friends for their miscellaneous support for making

this possible

GLOSSARY

AESS: AES

SONEL

AGC:

Automatic Generation Control

AMR:

Automatic Meter Reading

CD:

Collision Detection

CSMA: Carrier

Sense Multiple Access

DA:

Distribution Automation

DMS:

Distribution Management System

DTS:

Dispatcher Training Simulator

EMS: Energy

Management System

EPC:

Engineering, procurement and Construction

FA:

Feeder Automation

FAT:

Factory Acceptance Test

FOC: Fiber

Optic cable

GSM: Global

System for Mobile communication

HMI: Human

Machine Interface

HV: High

Voltage

IED:

Intelligent Electronic Device

ISD:

Information System Division

IT:

Information Technology

ITS:

Interchange Transaction Scheduling

MMS: Metering

Management Systems

MV:

Medium Voltage

NCC:

Northern Control Center

NIG:

Northern Interconnected Grid

NIN:

Northern Interconnected Network

OSI:

Open Systems Interconnect

OJT:

On-The-Job Training

NSCC:

National System Control Center

OHTL: Over

Head Transmission Line

PAC:

Provisional Acceptance Certificate

PMS: Power

Management System

RCC:

Regional System Control Center

RTU: Remote

Terminal Unit

SA:

Substation Automation

SCADA:

Supervisory Control And Data Acquisition

SAT I: Site

Acceptance Test

SAT II: System

Acceptance Test

SIG:

Southern Interconnected Grid

SIN:

Southern Interconnected Network

SOW:

Statement Of Work

WRMS: Water

Resource Management System

TSO:

Transmission System Operator

TDM: Time

Division Multiplexing

VDU: Visual

Display Unit

VHF: Very

High Frequency

UPS:

Uninterruptible Power Supply

YCC:

Yaoundé Control Center

RESUME

La « Business Integration » est

définie comme étant le processus d'opérationnalisation

durable d'équipements, afin d'assurer l'effectivité pour une

entreprise des valeurs ajoutées escomptées par l'acquisition de

ces équipements. Ce processus qui passe par l'implémentation des

équipements, le transfert technologique, l'internalisation et

l'appropriation peut se décliner sur trois dimensions

d'opérationnalisation : technologique, fonctionnelle,

organisationnelle. la « Business Integration » telle que

définie ci-dessus est envisagée dans le cadre de

l'implémentation des équipements matériels et logiciels

d'un système informatique.

Les « requirement for business

integration » consistent en l'ingénierie du processus de

« business integration » d'un système informatique

en vue de produire des spécifications pour assurer une bon

déroulement du processus dans les trois dimensions

évoquées ci avant : une implémentation correcte des

équipements (dimension technologique de l'intégration), le bon

usage des fonctionnalités (dimension fonctionnelle de

l'intégration), l'ajustement continu de l'organisation pour tirer le

meilleur partie de la technologie (dimension organisationnelle de

l'intégration). En d'autres termes les « requirements for

business integration » constituent le pivot de l'assurance

qualité pour une « business intégration »

réussie.

Le contexte des présents travaux est la mise en oeuvre

chez AES-Sonel d'un système informatique pour la planification, la

supervision, le contrôle et le comptage des flux d'énergie dans le

réseau électrique du Cameroun. Après avoir acheté

ce système AES-Sonel commence tout juste l'implémentation des

différents équipements qui le composent.

L'objectif des présents travaux est de (i)

détecter toutes les exigences de la BI de ce système

informatique, puis de (ii) spécifier chacune de ces exigences.

L'approche méthodologique utilisée à ces effets combine

l'ingénierie des projets d'implémentation de systèmes

informatiques, l'ingénierie des spécifications et

l'ingénierie des processus.

Au délà du stage, le travail se poursuivra par

une tentative de généralisation des résultats obtenus chez

AES-Sonel par la production de spécifications pour la mise en oeuvre

d'un logiciel d'assurance qualité pour la « Business

Integration » de tout système d'informatique dans une

entreprise donnée.

ABSTRACT

Business integration involves all the processes necessary in

bringing into full and sustained operation equipments (hard and soft) in order

to make sure that they satisfy the needs they were undertaken for during

buying. In case of information systems, business integration involves all the

processes from implementation through transfer and operation to ownership and

is divided into technological, functional and organization integration.

Developing requirements for the business integration of an

information system is a systems engineering process for business integration

with the main goal of producing specifications and quality assurance measures

to guarantee a successful business integration, hence ensuring correct

implementation of equipments (technological integration); proper, full and

sustained use of equipment functionalities (functional integration) and

continual appropriate organizational adjustment to ensure that the complete

technological and functional benefits of the equipments are obtained. In other

words, these business integration requirements and their corresponding

specifications, form the most important quality assurance measures for

successful business integration.

The context of this dissertation resides on the fact that AESS

has bought and is about to implement the equipments (hard and soft) of an

information/computer system for use in managing the operations on the whole

Cameroonian electricity transmission network

The objective of this dissertation is to (i) elicit all the

requirements and aspects for the business integration of this information

system and (ii) develop their corresponding specifications. In this light, the

adopted methodology combines aspects of information systems project

implementation, requirement engineering; change management; process

reengineering and technology transfer.

This work would be followed by another project that would try

to generalize the results obtained for AESS in producing specifications for the

development of a quality assurance software for the business integration of an

information system in any given business/company.

TABLE OF CONTENTS

DEDICATION

1

ACKNOWLEDGEMENTS

2

GLOSSARY

6

GENERAL INTRODUCTION

15

CHAPTER 1: CONTEXT AND PROBLEM

DESCRIPTION.................................17

1.1: INTRODUCTION

18

1.2: PRESENTATION OF AES SONEL

18

1.2.1: History

18

1.2.2: Mission

18

1.2.3: Organization of AES Sonel

18

1.2.3.1: Hierarchical organization of AES Sonel

18

1.2.3.2: Organization of the network operations

department

19

1.2.4: Description of the AES Sonel network

20

1.3: Problem location and description

23

1.3.1: Existing operations management system

23

1.3.1.1: Processes

23

1.3.1.2: Procedures

23

1.3.1.3: Resources

24

1.3.1.3.1: Human resources

24

1.3.1.3.2: Systems

24

1.3.1.3.2.1: Existing SCADA system

25

1.3.1.3.2.2: Existing telecommunication system

27

1.3.1.3.2.2: Softwares

29

1.3.2: The TSO and the new electricity market

system

29

1.3.3: Problem statement

32

1.3.4: PMS description

32

1.3.4.1: Compositional overview

33

1.3.4.2: Technical Overview of PMS

34

1.3.4.3: Functional Overview of PMS

38

1.3.5: The Business Integration problem

43

1.4: Scope of work and specific objectives

44

CHAPTER 2:

METHODOLOGY.....................................................................45

2.1: INTRODUCTION

46

2.2: Technology transfer

46

2.3: Technology transfer project management

48

2.3: Information systems project implementation

49

2.4: Requirement engineering

52

2.4.1: Requirement gathering

52

2.4.2: Requirement analysis and specifications

development

54

2.5: Change management

55

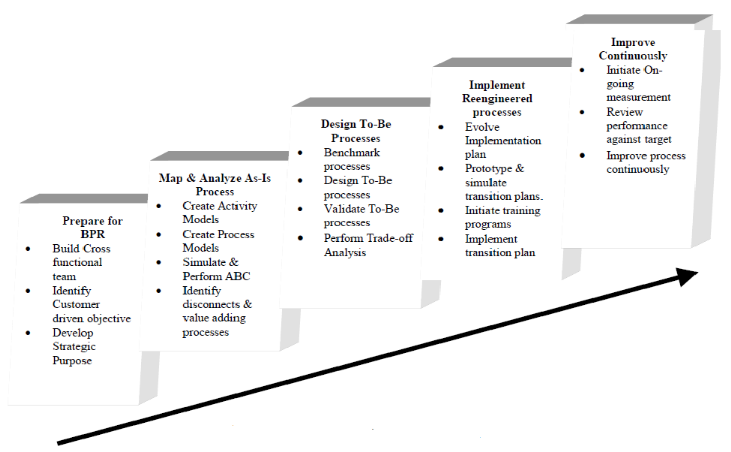

2.6: Business Process Reengineering (BPR)

57

2.3: Conclusion

60

CHAPTER 3:

RESULTS...............................................................................61

3.1: Introduction

62

3.2: Requirements for PMS business integration

62

3.2: PMS business integration requirements

specifications

62

3.2.1: Technological requirements

62

3.2.1.1: Pre-requisites for implementation

62

3.2.1.1.1: Human Resources

63

3.2.1.1.1.1: Implementation

63

3.2.1.1.1.2: Project Follow-up and Handling

63

3.2.1.1.1.3: Systems Operation and Business

Integration (BI)

65

3.2.1.1.2: Civil, Construction and adaptation

Works

66

3.2.1.1.3: Telecommunication Infrastructure

66

3.2.1.2: QUALITY DATA FOR SYSTEM

67

3.2.1.2.1 Organizational Data

67

3.2.1.2.1.1 Transmission Network Plan

67

3.2.1.2.1.2 Telecommunication Network

Infrastructure

67

3.2.1.2.1.3 Profile Data for System users (System

Operators and System Administrators)

68

3.2.1.2.1.4 Generation System Owner Data

68

3.2.1.2.1.5 Transmission System Customer/End User

data

68

3.2.1.2.2 Referential Data

69

3.2.1.2.3 SCADA Process Data

70

3.2.1.2.3.1 Controls

71

3.2.1.2.3.2 Status

71

3.2.1.2.3.4 Measurements

72

3.2.1.2.4 EMS Process Data

72

3.2.1.2.4.1 Generation Process Data

72

3.2.1.2.4.2 Network Application Process Data

73

3.2.2 Organizational requirements

74

3.2.2.1 Operations reengineering

74

3.2.2.2 Organizational reengineering

77

3.2.3 Operational requirements

79

3.2.3.1: Systems rollout

79

3.2.3.2: Training

79

3.2.3.2.1 Objective

80

3.2.3.2.2 Training types

81

3.2.3.2.3 Training Plan

81

3.2.4: Maintenance and Support

82

3.2.4.1: Maintenance and Spare Part Replacement

Strategy

82

3.2.4.2: Support Strategy

84

3.2.5: Documentation

84

3.2.5.1: Hardware Documentation

84

3.2.5.1.1: Equipment Documentation

85

3.2.5.1.2: Installation Documentation

85

3.2.5.2: Software Documentation

86

3.3 Quality assurance measures conformance

checklist for business integration

86

3.3.1: Telecommunication systems quality assurance

conformance checklist

86

3.3.2: Systems rollout quality assurance

conformance checklist

87

3.3.3: Training quality assurance conformance

checklist

87

3.3.4: Documentation quality assurance conformance

checklist

88

CONCLUSION AND

PERSPECTIVES.............................................................89

BIBLIOGRAPHY/REFERENCES....................................................................91

ANNEX...................................................................................................93

TABLE OF FIGURES

Figure 1: Hierarchical organizational chart of

AESS

16

Figure 2: Organizational chart of the network

operations department

17

Figure 3: The southern grid

19

Figure 4: The northern grid

20

Figure 5: SCADA systems on the southern grid

23

Figure 6: Control room at dispatch center, Magombe,

Edea, Cameroon.

24

Figure 7: Future hierarchical

dispatching structure

28

Figure 8: Compositional overview of PMS system

31

Figure 9: SCADA/PMS system Overview

32

Figure 10: Principle overview of system control

center, Cameroon

35

Figure 11: PMS subsystems functions

37

Figure 12: Metering Management system

40

Figure 13: A system

44

Figure 14; The system development life cycle is

sometimes called the waterfall method

46

Figure 15: Process data diagram for the change

management process

54

Figure 16: Business process reengineering

consolidated methodology

57

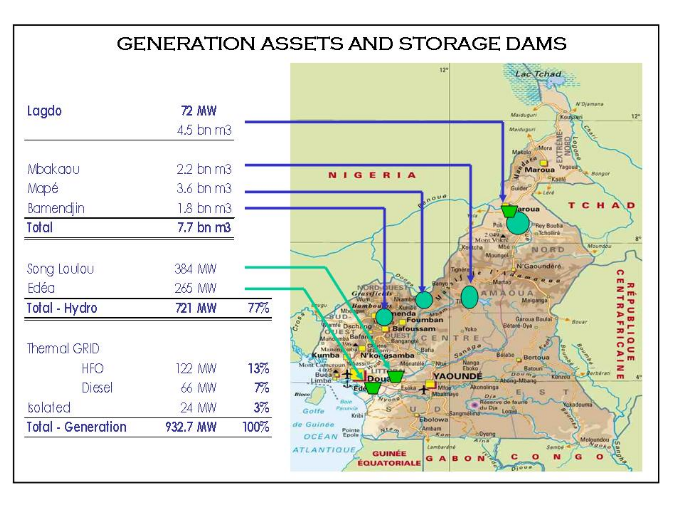

Figure 17: Generation assets

and storage dams foe AES Sonel

a

Figure 18: National System Control Center (NSCC),

Douala

b

Figure 19: North Control Center, Garoua

c

Figure 20: Yaoundé Control Center,

Yaoundé

d

THIS PAGE IS INTENTIONALLY LEFT BLANK

GENERAL INTRODUCTION

In July 2001 AES acquired 56% of the shares of the sole

electrical energy service provider company Sonel. The concession agreement

signed between AES and the Cameroon government requested the modernization of

equipments and operations management of the new company AESS as a progressive

move towards the liberalization of the Cameroon electricity market system. This

new electricity market structure requires the unbundling of the Transmission

System Operator (TSO) from AESS. In order to ensure security and reliability in

electricity network and market operations, the TSO as the system operator with

exclusive right to operations management, shall share the same information and

information system facilities with AESS who conserves asset owner

responsibilities and exclusive rights to provide transmission services.

Requirements

In line with the above, AESS has decided to implement a new

Power Management System (PMS). The PMS is an IT-based solution package composed

of SCADA infrastructures on top of which specific software are implemented to

manage planning, supervisory control, and the accounting of electricity flows

between the main nodes of the network. Given the importance of this new system,

the large total cost of ownership associated with acquiring and running it,

AESS is facing challenges on its appropriate business integration.

More precisely, the business integration project of the

new SCADA/PMS at AESS would consist of integration in three dimensions : (i)

integrating technology in terms of implementation by the EPC contractor

(Siemens) as defined in the system design specifications; (ii) integrating

functionalities in terms of systems rollout, system documentation, maintenance

and support planning, training users to ensure sustainability of the system

service delivery; (iii) integrating organization in terms of business

operations re-engineering to ensure that both network operations management and

the new electricity market stakeholders derive expected project benefits.

Therefore, in order to ensure full ownership of the technology

and effectiveness of the expected benefits from the new SCADA/PMS system, AESS

has decided to analyze and study all the requirements and aspects across the

above three axes, in the bid to design specifications for an efficient business

integration solution.

The job during the internship at AESS was to do a requirement

study for the business integration of the SCADA/EMS module (one module of the

PMS).

Chapter 1 presents the context and background and then states

the problem to be solved with the goals and objectives to be attained. In order

to give a clear picture of the problem being solved, this chapter also gives an

overview of the technologies to be integrated.

Chapter 2 exposes some concepts and state-of-the-art

techniques as well as adopted the methodology used in doing the requirements

study.

Chapter 3 presents a summary of the results (the different

aspects and requirements for business integration with their corresponding

specifications) and some of their benefits in terms of quality assurance

measures for AESS's business integration project.

This work finishes with a conclusion, project status at AESS,

and the in terms of next steps of my internship project and my research

work.

.

CHAPTER 1

CONTEXT AND PROBLEM DESCRIPTION

1.1:

INTRODUCTION

This chapter briefly presents AESS as well as stating the

problem to be solved with the scope of work, goals and objectives to be

attained. Also, in order to give a clear picture of the problem being solved,

this chapter also gives a brief overview of the technologies to be

integrated.

1.2: PRESENTATION OF AES

SONEL

1.2.1: History

SONEL was founded in 1974, born of ENERCAM which was in turn

the daughter of Electricte du Cameroon. It became AES Sonel on the 18 July 2001

when 56 % of the capital was transferred to the American group AES CORPORATION,

one of the world's largest private electricity companies. It is a public

limited company and is the sole electrical energy service provider company in

Cameroon till date.

1.2.2: Mission

The mission of AESS is to generate, transmit and distribute

reliable energy in compliance with safety standards as well as supply to

Cameroon industry reliable and clean energy with a high sense of social

responsibility. AESS caries out this mission within the framework of the

concession agreement and electricity sale license agreement that both determine

the perimeter, modalities and conditions.

1.2.3: Organization of AES

Sonel

1.2.3.1: Hierarchical

organization of AES Sonel

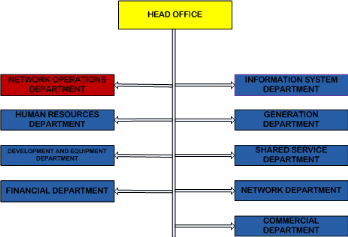

AESS is structured into departments, sub-departments,

divisions and services. It is organized into 9 departments and my internship

took place at the network operations department depicted in red in the figure

below which displays the organizational chart of AESS. Each of these

departments is subsequently organized into sub-departments made up of divisions

and services. The head office headed by the GM/CEO is organized into a

communications sub-department, a legal affairs sub-department, a compliance

sub-department, a safety and environment sub-department and a community

partnership section. Part of my internship also took place at the productions

department and the network departments.

Figure 1: Hierarchical

organizational chart of AESS

1.2.3.2: Organization of the

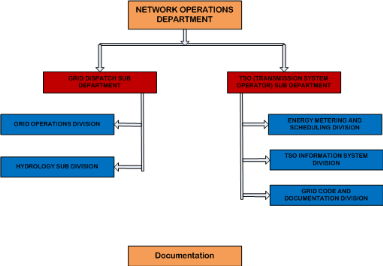

network operations department

The network operations department is organized into

sub-departments, sub-division and division as depicted in the figure below

Figure 2:

Organizational chart of the network operations department

The network operations department, future Independent System

Operator/Transmission network Operator (TSO), is presently responsible for

managing all the operations on the electricity transmission network. It carries

out this mission through the following divisions with their respective

functions

· Grid operations Divisions: Located at the Grid Dispatch

center in Magombe, Edea is responsible for supervision and control of the

electricity transmission network, data management, capacity planning and

operations planning.

· Hydrology Sub-division: Located at the Grid Dispatch

center, is responsible for managing and providing information concerning the

water levels and flow rates in the production dams, storage dams and on the

Sanaga and Benue river

· Metering and Scheduling division; responsible for

operations planning, metering, energy accounting and billing.

· Information system division: responsible for the

management (design, maintenance and support) of the information system used in

network operations management as well as the establishment of communication

procedures for the network operations department.

· Grid code and documentation division: establishment and

management of the grid code.

1.2.4: Description of the

AES Sonel network

AESS carries out its mission of generating, transmitting and

distributing reliable electrical energy of excellent quality in compliance with

safety standards through a generation network made up of both thermal and hydro

generating power stations, a transmission network made up of two isolated grids

(the northern grid and the southern grid) and a low voltage distribution

network.

AESS has an up-to-date an installed generation capacity of

about 900MW of which about 88% is hydro and 12% is thermal. Its two main hydro

power stations, Edea and Songloulou with installed generation capacities of

265MW and 384MW respectively are located on the Sanaga River. Another hydro

power station is located in Lagdo, on the Benue River, with an installed

generation capacity of approximately 72MW. These three hydro plants are

supplemented by thermal plants (HFOs and LFOs) located in Limbe, Douala,

Yaoundé and Bafoussam. About 30 aging diesel power stations that supply

isolated centers in the country.

Transmission through the SIG is done using MV (30/15KV) and HV

(225/90KV) power lines. The figure below depicts the whole SIG showing all its

substations and power stations.

Figure 3: The southern

grid [26]

As a summary and as can be seen from above, the SIG has

Ø 29 substations (both 225/90KV and 90/30/15KV)

Ø 2 hydro power stations

Ø 4 Heavy Fuel Oil (HFO) thermal power stations

Ø 5 light Fuel Oil (LFO, Diesel) thermal Power

stations

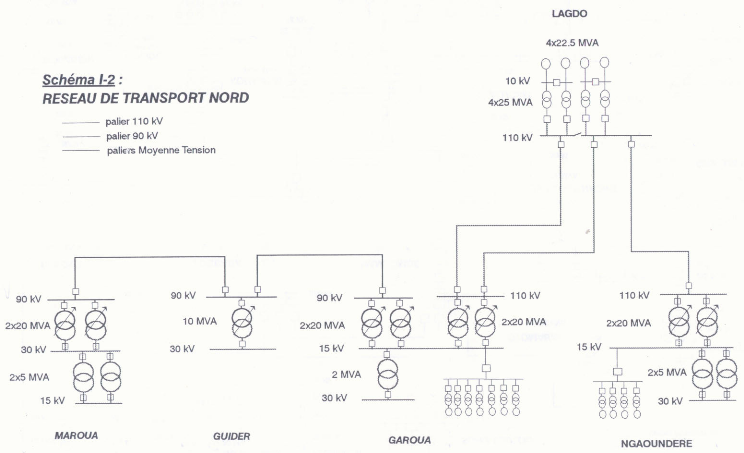

Transmission through the NIG is done using MV (30/15kV) and HV

(110/90kV) power lines respectively. The figure below depicts the NIG showing

all its power stations and substations

Figure 4: The northern

grid [26]

As a summary, the NIG is made up of

Ø 5 substations

Ø 1 hydro power station

Ø 1 thermal power station

Distribution is done through a highly radial LV (400/380V)

network using MV/LV transformers. AESS presently serves 528,000 customers,

which constitutes 60% of the urban population and 30% of the rural population.

Billing is done using 365 grid connected meters on the northern grid and 1300

grid connected meters MV points on the southern grid.

1.3: Problem location and

description

1.3.1: Existing operations

management system

The entire existing operations management system used by the

network operations department for the management of all the operations on the

electricity transmission network is organized into processes, procedures and

resources.

1.3.1.1: Processes

The processes involved in transmission network operations

management which represent an audit of the main technical activities of the

network operations department include

v Capacity planning: demand planning

forecasting, load flow and stability assessment, technical studies and

enquiries, replacement and refurbishment planning and transmission system

improvement efficiency.

v Operations planning: water flow and load

forecasting, generation scheduling, production simulation including costing and

budgeting, active and reactive power dispatch optimization and transmission

reliability and efficiency.

v Data management: data preparation including

collection and warehousing, energy accounting (power exchange metering

operation), technical performance reporting.

v Supervision and control: grid dispatch

logistics, system real time monitoring and control, power system restoration,

control room resource scheduling and system data and event logging.

v Water resource management: management of

the water level and flow rate in the storage dams, productions dams and the

hydro stations on the Sanaga River.

v Metering and scheduling: billing, energy

and production counting, energy and production costing, energy allocation,

energy balancing, energy flow registration, losses calculation, meter reading

and meter data collection, contract management, meter maintenance and metering

infrastructure management.

v General: training, information exchange, IT

infrastructure maintenance and support.

1.3.1.2: Procedures

There exist well established procedures in operating

instructions manual for all the above processes of which detailed description

is out of scope of this work. For example, for the supervision and control

process, there exist different procedures to be used by the grid

dispatch/system operators in restoring the power system to the normal state

from an alert state, an emergency state, a critical state or a black-out state

and of which there also exist different procedures for restoring the power

system to the normal state from a black-out state resulting from a fault,

insufficiency in production capacity, maintenance intervention, failure of a

major equipment or system e.t.c.

1.3.1.3: Resources

The resources used managing operations on the transmission

network can be divided into human resources and systems (technologies,

softwares)

1.3.1.3.1: Human

resources

The network operations department organized into a grid

dispatch sub-department and TSO sub-department has at its head an engineer

(departmental head).

The grid dispatch sub-department headed by a senior operations

engineer (the sub-departmental head) is structured into an operations division

and a hydrology sub-division. The operations division is made up of 11

employees with a senior electrical engineer at the head (operation divisional

head) and a team of 10 dispatchers/system operators working on shifts of 8

hours per day and 7 days a week while the hydrology sub-division is made up of

about 10 employees with a senior hydrology engineer at the head (divisional

head), 2 hydrology technicians responsible for collecting and analyzing

hydrological data obtained by the other technicians dispersed at the different

hydro stations on the Sanaga river and at the production dams.

The TSO sub-department headed by a senior engineer is

structured into an information system division, a metering and scheduling

division and a grid code and documentation division. The information system

division is made up of a 1 employee (the divisional head) while the metering

and scheduling division is made up of 3 employees with a senior engineer at the

head (divisional head) and a team of 2 technicians to assist the engineer in

his function to carry out the division's mission.

1.3.1.3.2: Systems

Even though most of the underlined processes involved in

operations management cited above are carried out manually, there exist

nevertheless some operations management systems/technologies to aid in their

management.

1.3.1.3.2.1: Existing SCADA

system

Supervision and control of all the operations on the southern

transmission network is done in the control room at the grid dispatch center in

Edea using two SCADA systems deployed on the southern transmission network, the

SKAN4 since 2008 and the LS 2000 since 1979 running in parallel and by a team

of 10 grid dispatch operators working on a shift of 8 hours per day. These two

systems are depicted in the figure below where components of the SKAN4 system

are colored in red

Figure 5: SCADA systems

on the southern grid [1]

This control room depicted in the figure below is made up of a

control desk with two operator stations, each with also two MMI color 21"

Displays, corresponding keyboards and event printers available for display,

printing, control and monitoring of limited parts of the 225 kV/90 kV network

substations and power stations of the southern grid.

The SCADA system supplied by «Landys & Gyr«

consist of redundant (main and back-up) master computers of type LS 2000 to

process information acquired and transmitted from the Substations and Power

stations through the installed RTUs, 7 from type Telegyr 709 as Master RTUs and

12 from type Telegyr 065 as slave RTUs [1]. The information to be processed

includes

§ Critical and non critical alarm signals (AN and AC)

§ Single indications (TS)

§ Double indications (IM and IR)

§ Telecontrols (TC)

§ Measurements (TM)

§ Query signals (QG)

Figure 6: Control room

at dispatch center, Magombe, Edea, Cameroon.

All data from and to the substations and power stations RTUs

are transmitted with 200 Baud Power Line Carrier (PLC) links using the 225 kV

and 90 kV overhead line conductors.

A mimic board is also installed at the control room in front

of the operator desk. Only few information (status indications, alarms and

measurements) acquired directly from the Mangombe Substation are still

available at the mimic board [1]. At the control center the mimic board is

presently used mainly as a passive network single line information board and as

the conventional back up local control panel for the Mangombe 225/90 kV

Substation.

The SKAN4 system supplied by `Siemens' and which runs in

parallel with the LS 2000 system has a similar configuration with the LS 2000

system but consist of 15 TG 805 and 2 TG 065 RTU/data concentrators sending

signals (status, measurements, alarms and control signals) back to a redundant

(master and back-up) set of MMIs for processing through a PLC communication

link. The one operator station with the computers for monitoring, supervision

and control has one keyboard, a mouse and a separate printer for event

printing.

1.3.1.3.2.2: Existing

telecommunication system

The existing telecommunication systems in use for SCADA in

Cameroon (in the southern grid) comprise mainly Power Line Carrier (PLC),

UHF/VHF and Microwave radio links, some Fiber Optic (FO) links installed in

recent time. The telecommunication network is used for transmission of SCADA

data (from some 20 substations and power stations in the 90kV and 225kV

network) and operational voice communication. Except for some links in the

Southern grid, redundant telecommunication paths do not exist.

There are another 5 stations in the north of the country, connected via PLC to

the 90/110kV grid. The PLC links in the northern grid are only used for voice

communication [1]. At present there is no hierarchical structure with regional

control centers i.e. the RTUs send their telegrams directly to the SCC, which

is the high level control center.

The following bullets show the basic SCADA communication

concerns:

· Only some 20 RTUs (out of approx. 30 stations that will

be situated in the 90/225kV southern grid in the future) are connected to the

control center today.

· SCADA data transmission between the RTUs and the

control center is using data channels with transmission speed of 200 bit/s.

For operational voice communication besides the PLC network;

GSM, Cisco IP phones and VHF radio based telephone system are installed for

connection of the SCC and the power stations and substations and other

administrative offices for AESS all over the country. AES SONEL is also using

public telephone lines for the operational voice communication [1].

Besides the usage of PLC, GSM, Cisco IP phones, VHF and

Microwave links, connections to the public telephone services are partly being

used for administrational voice communication from AES SONEL main office with

offices all over the country. Data communication is mostly being done through

emails using an intranet system.

1) PLC (Power Line Carrier) system

Most of the existing PLC terminals are manufactured by AREVA

(former CEGELEC-ALSPA), some by ABB (former BBC). For PLC communication AES

SONEL, is utilizing the frequency range from 40 kHz-500 kHz. The coupling

method used is phase-to-ground coupling [1]. The PLC terminals have a 4 kHz or

2X4 kHz bandwidth respectively, which is used to transmit voice and data

information. Between the substations Logbaba and Koumassi (8.3 km) and between

BRGM and Oyomabang (4 km), each one PLC link is interconnected through coaxial

cables (50 ohm), which are integrated inside the 90 kV overhead line ground

wire. The last part of ground wire between Logbaba and Koumassi is embedded in

the earth with the 90 kV cable. The age of the PLC installations ranges from

some years to over 25 years. Spare parts for the older types of PLC terminals

are expensive or not available any more [1]. Especially for larger stations and

for the interconnection of the power stations to the SCC, the SCADA data

transmission speed of 200 bits/s is insufficient compared to state of the art

SCADA systems. Most of the installed PLC terminals are not operational while in

some cases only voice communication is possible, and the status of some links

is such that they do not provide a reliable transmission medium for the

transmission of SCADA data. Especially with the implementation of standard

protocols (IEC 60870-5-101 and -104) for connection of RTUs to the Control

Center, it is a vital requirement to install reliable data links providing

sufficient data rates.

2) Radio systems

AES SONEL uses UHF/VHF and Microwave equipment in their radio

system. The radio links are used for voice communication to substations, power

stations and to AES SONEL offices (for administrative purposes) [1].Presently,

12 VHF relay stations, with 8 for the south and 4 for the north, cover the

essential routes of HV, MV and LV AES-SONEL electrical

network. Each relay station is corresponds to an independent

sub network and the sub-networks are not interconnected between each other [1].

The majority of the installed radio equipment is manufactured by Motorola of

which some those especially the microwave equipments are non-functional while

some have been abandoned.

3) Fiber optic system

AES SONEL's fiber optic system is presently made up of some fiber

optic cables installed by AES SONEL in the southern grid with the total length

of these fiber optic links summing up to approximately 288 km [1].

4) Telephone system

For operational voice communication within the AES SONEL; PAX

based telephone, GSM and IP telephone systems are connecting the Control

Centers, power stations, substations and administrative offices [1].

For voice communication between the SCC, substations and power

stations in the southern grid of AES SONEL, PAX based telephone systems of

various types and status are installed. The transmission is mainly using the

existing speech channels (4 kHz) of the interconnected PLC equipments between

the substations and power stations. PAX telephone systems are also installed in

the substations and power stations of the northern grid [1].

Operational communication is using not only using the existing

AES SONEL owned telecommunication network, communication with many substations

is also through the Public Telephone Network [1].AES SONEL offices are using

various communication paths for voice and data communication for administrative

purposes (AES SONEL owned as well as Public Telephone Network) such as Cisco IP

phones over the fiber optic links, MTN GSM mobile phones and an intranet system

for data communication over the fiber optic link

1.3.1.3.2.2: Softwares

Apart from some excel sheets used by the hydrology department

in the analysis of hydrological data and the SCADA software, the main software

used by the network operations department is operations and capacity planning

is the QSOM (Quantitative systems for Operations Management) software. It is

used in daily dispatching through unit commitment and the establishment of a

production plan.

1.3.2: The TSO and the new

electricity market system

The process to open-up the electricity markets system in

Cameroon as stated by the new electricity law started after the privatization

of SONEL on the 18 July 2008 by the American AES Corporation. AESS would soon

share the electricity market in Cameroon with Independent Power Producers

(IPP), Independent Transmission Companies (ITCs) and independent retailers

including large customers [2].

The TSO (Transmission System Operator) presently part of the

network operations department would be unbundled from AESS and assigned to a

subsidiary of AESS as stated in the concession agreement. AESS shall conserve

transmission assets, asset owner responsibilities and exclusive rights to

provide transmission services in the scope of transmission while the TSO shall

conserve exclusive right to managing operations on the transmission network.

The TSO would be at the heart of this new electricity market

system as demonstrated in the future hierarchical dispatching structure

below

Figure 7: Future

hierarchical dispatching structure [3]

The TSO in this new electricity market structure has as

mission the following [23];

1. Maintain the security and the balance of load flows on the

Transmission system and undertake the management of network power flows, taking

account of exchanges within the interconnected network;

2. Maintain the reliability and security of the Transmission

system, taking account of constraints upon the latter, and implement such

measures as are required to ensure the availability of all the requisite

auxiliary services and the maintenance of a high level of reliability and

security on the electric system;

3. Ensure the optimum use of existing capacity;

4. Manage the take-up of available electricity production at

the lowest possible price, preferably from the national market in case of

exports, in accordance with functions in the general interest to be undertaken

by the Transmission System Operator;

5. Guarantee the availability of management data and ensure

that interested parties receive any information required for the purposes of

billing and the settlement of payments in respect of services provided;

6. Not practice any discrimination between system users,

subject to the limits of available capacity;

7. Supply to the operator of any other system which is

connected to the SONEL system sufficient information to allow the secure,

effective and coordinated operation of interconnected networks;

8. Facilitate the interconnection of systems under the terms

of agreements concluded with any other system operators, participate in the

implementation of rules governing interconnection and supervise compliance with

these rules;

9. Prepare and submit to the Agency an annual estimate of

Generating capacity, Transmission capacity and Distribution capacity connected

to the system; and

10. Identify requirements for interconnection with other

systems, potential Transmission capacity and electricity demand for the next

ten (10) years; this analysis will be updated and submitted to the Agency each

year.

In order to aid the TSO to properly execute its functions and

carry out its mission, AESS is about to put into operation a new PMS (Power

Management System) on the whole Cameroonian electricity transmission network

which also forms part of the context of this work and of which the TSO (more

specifically, the information system division under which i did my internship

and of whom this dissertation concerns) has as obligation under this context

Ø Project ownership responsibilities for the

implementation of the Power Management System (PMS) [23]

Ø Coordination of the proper operational integration of

the PMS in business processes within the AESS [23]

And of which the business integration of this PMS in line with

the PMS project opening memo is the last phase for the complete realisation of

these obligations.

1.3.3: Problem

statement

Based on the concession agreement signed between AES and the

Cameroonian government which requested [2]

1) Modernization of company equipments

2) Modernization of operations management

AESS is about to put into operation a new PMS for the

supervision, control and management of operations on the whole Cameroonian

electricity transmission network. Also in order to ensure security and

reliability in electricity network and market operations, this information

system and the information obtained would be shared between the TSO (system

operator, who has exclusive right to operations management) and AESS

(concession holder, who conserves asset owner responsibilities and has

exclusive rights to provide transmission services).

Faced with a business integration challenge which key to

correct implementation, complete technology transfer, proper operation and the

absolute ownership of this system; AESS has decided study and analyze all the

requirements and aspects for the business integration of this system in the bid

to design specifications and quality assurance measures for efficient business

integration.

In other words, it involves designing quality assurances

measures (requirements and specifications) used in the subsequent development

of a number of quality assurance checklists to ensure the efficient business

integration of this new PMS system. These quality assurance checklists to be

established subsequently would be used to demonstrate compliance with the

defined business integration requirement specifications upon completion of

business integration to ensure correct implementation; full, proper and

sustained operation; complete technology transfer and absolute ownership of

system.

1.3.4: PMS

description

The PMS is an IT-based solution package composed of SCADA

infrastructures on top of which specific softwares are implemented to manage

operations such as planning, supervisory control, energy accounting between the

main nodes of the network e.t.c. More specifically, it is an information system

with information management infrastructures/systems for real-time analysis of

information.

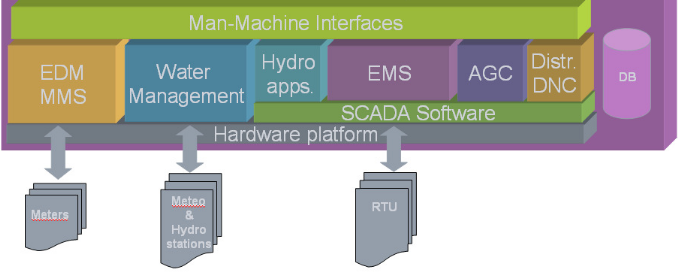

1.3.4.1: Compositional

overview

The new PMS system to be supplied by Siemens (EPC contractor)

and to be business integrated is made up of the following three subsystems with

their corresponding main operational objectives;

1. SCADA/EMS with main operational objective the optimization

of network monitoring and control as well as switching operations for a better

system security and reliability [2]

2. Water Resources Management System (WRMS) with main

operational objective the optimization of the water discharge from the storage

dams for an efficient energy generation and water use in the hydro power plants

[2]

3. Automatic Meter reading/Metering Management System/Energy

Data Management system (AMR/MMS/EDM) with main operational objectives the

provision of reliable metering data from any major grid node of the overall

system network to all entitled stakeholders and the determination of electrical

losses inside the electrical supply system of Cameroon [2].

The compositional overview of the PMS is depicted in the

figure below where real time data/information from the substations and power

stations, the meteo and hydro stations and grid metering points acquired and

processed by their respective hardwares; RTUs/data concentrators,

meteorological/flow meters and grid connected meters; are transported over a

telecommunications network to an interface hardware platform (made up of

servers, switches, e.t.c) to be analyzed and processed by their respective

softwares (information management systems); SCADA/EMS, EDM/MMS and WRMS

softwares.

Figure 8: Compositional

overview of PMS system [5]

1.3.4.2: Technical Overview

of PMS

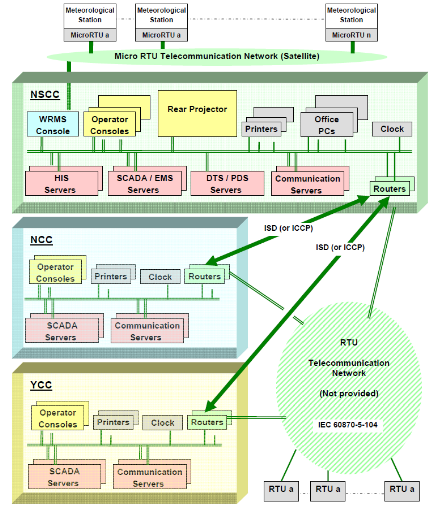

This IT-based solution package is made up of both hardware

(network and control) and software components. The major network and control

components of this PMS to be installed at the different substations, power

stations, hydro and meteo stations and at the system controls centres are

depicted in the figure below showing an overview of the PMS

Figure 9: SCADA/PMS

system Overview [5]

All the different data acquisition stations and system control

centers have communication buildings containing all the different

telecommunication equipments such as communication back-up power supplies e.g.

UPS, diesel generator, battery e.t.c; data concentrators; switches; routers and

the fiber optic nodes e.t.c. All sensors and data acquisition equipments at the

different data acquisition stations and grid metering points are connected

through a highly redundant communication network to system control centers for

information and operations management.

All RTUs communicate with the SCADA system through dedicated

data channels. They will have single and double pole statuses, analog and pulse

accumulator inputs, as well as supervisory control outputs for switching of

circuit breakers and isolators as well as raise/lower controls for tap-changing

transformers. These RTUs communicate in [1]

Ø IEC 60870-5-101 (balanced and unbalanced mode)

Ø IEC 60870-5-104 (which is TCP/IP and thus

routable)

Ø dual-port-communication either

o With homogenous protocols (IEC 101-101 / IEC 104-104)

o Or with mixed protocols (IEC 104 main channel / IEC 101

standby channel).

Ø With a future capability of communicating in the IEC

61850

Six different telecommunication systems make up the

telecommunication network associated to this new PMS system for voice and data

transmission and include [1]

Ø OHTL (Over-Head Transmission Line) Power Line Carrier

suitable for voice, SCADA data, corporate data and hotline telephones

Ø GSM fixed mobile facility at each substation

Ø Low Power VHF (Very High Frequency) link to remote

offices

Ø Satellite link to the Garoua office in the North

Ø Microwave link

Ø FOC (Fiber Optic Cable) laid in the way leave of the

existing OHTL's

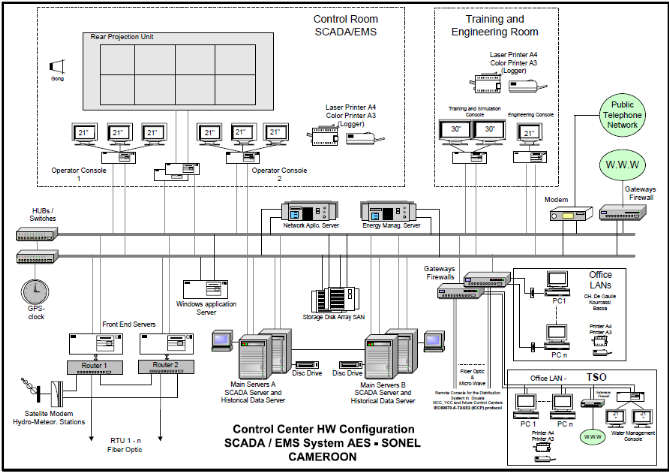

At the system control centers, functions (information

management systems and their corresponding applications) are compartmentalized

into functional blocks/subsystems with the subsystems implemented on different

servers and the servers distributed along a redundant Local Area Network (LAN).

All the information managements systems (SCADA, EMS, WRMS, MMS and EDMS) and

their corresponding application are critical in operations management and are

hence implemented on dual redundant servers, with one of the servers serving as

a hot standby. All the servers, workstations and network equipments are

interconnected through a redundant fast Ethernet LAN using Ethernet switches.

The most important and fundamental hardware equipments found in all the system

control centers include [5]

§ Application and system servers, performing all the main

data processing tasks and acting as the information reference sources for the

entire system. Critical applications are implemented on dual redundant servers

with one of the servers functioning in the hot standby mode.

§ Multiple workstation consoles with about 3 VDU per

workstation. The workstation consoles are configured for different purposes

(Operator, Engineering, Maintenance, Training e.t.c).

§ Large wall display unit connected to the real-time LAN

to rear-project any displays that would ordinarily be visualized on a

workstation

§ Redundant fast Ethernet 10/100base T switches to

interconnect the different system control center equipments

§ GPS time and Frequency System (TFS)

§ Redundant color and Black & white printers

accessible from workstation consoles for printing of the operating status of

the network anytime an event occurs.

§ Redundant WAN routers for interconnection to other

control centers and RTUs

§ Firewalls for connection to other LAN and WAN such

corporate office LAN, TSO LAN, the internet

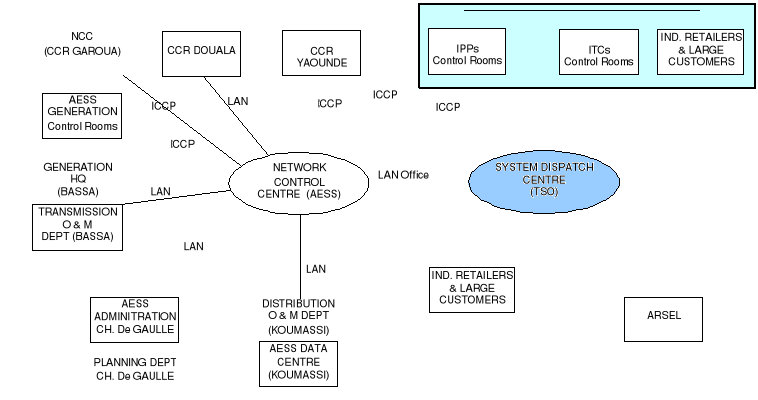

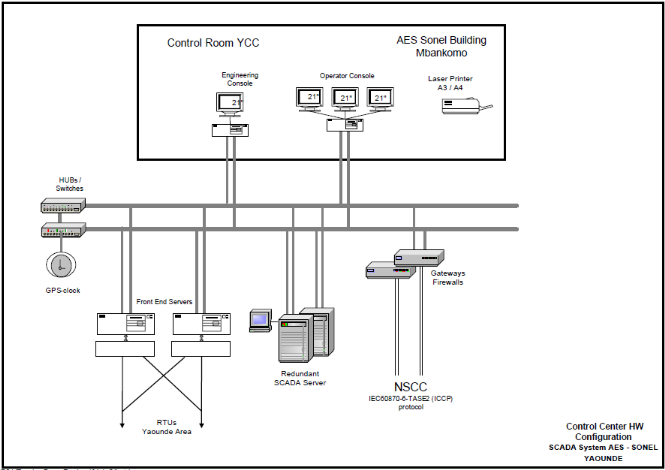

This new PMS as depicted in the figure above would be

implemented on three system control centers with the following borders of

operational responsibility [5]

1. A National System Control Center (NSCC) to control and

monitor the entire HV network of AES SONEL in Cameroon, including the outgoing

MV feeders, located in Douala and made up of SCADA and EMS applications.

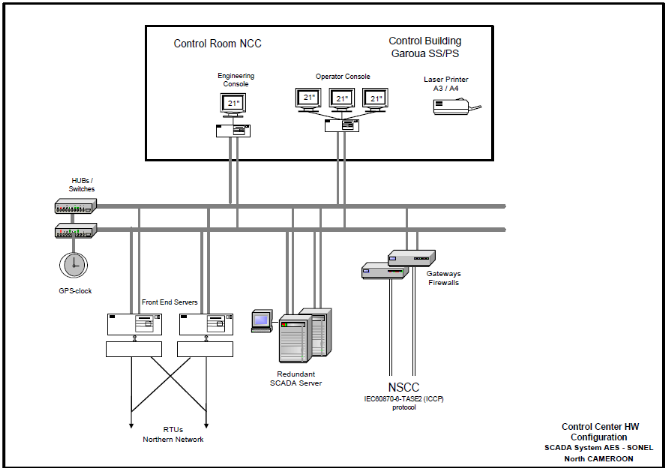

2. A regional Northern Control Center (NCC) to control and

monitor (in case of break-down of data communication to Douala) the isolated HV

network of the North, including the outgoing MV feeders, located in Garoua and

made up of only SCADA applications.

3. A back-up Yaoundé regional Control Center (YCC) to

control and monitor (in case of break-down of data communication to Douala) the

Yaoundé HV network including the outgoing MV feeders located in

Yaoundé and made up of only SCADA applications.

Also, regional distribution grid monitoring and partial

control would be done at the system control centers and by the regional

distribution control centers (CCRs) in the future.

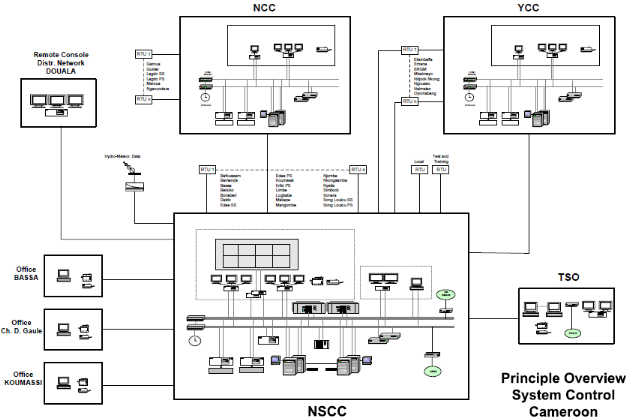

LAN connections shall be installed between the AESS offices in

Douala (Bassa, Charles de Gaulle and Koumassi), the system control centers and

the TSO offices for information sharing on transmission and distribution

planning and maintenance by AESS as well as on other issues such as energy

dispatch, hydro-thermal scheduling/coordination and water management by the TSO

as depicted in the figure below which shows an principle overview of the PMS

and the future hierarchical dispatching system.

Figure 10: Principle

overview of system control center, Cameroon [1]

Also as depicted in the figure above, there will be an

operator workstation with a three screen Console for each distribution network

((Yaoundé (YCC), Garoua (NCC) and Douala (Remote

console)). For the distribution grid of Douala one operator

workstation and corresponding Console will be located in the same building as

the SNCC. The subsystems (back-up Control Centers, YCC and NCC) for

Yaoundé and Garoua will be located at the AESS building in Mbankolo and

the control building of the Garoua SS/PS. From these workstations the MV

feeders in the corresponding HV/MV substations can be remotely controlled and

supervised.

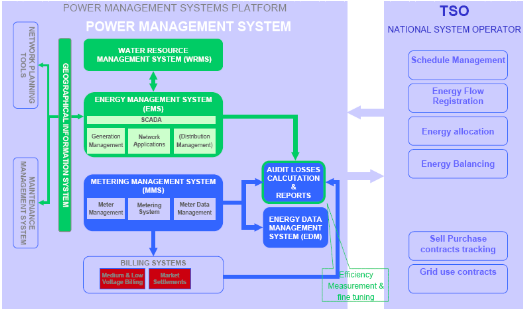

1.3.4.3: Functional

Overview of PMS

Any time there is a change of state in the network as a result

of an event, signals (alarms, status, measurements and control signals) from

the sensors and actuators locally controlling the different substation and

power station equipments, stored and processed in the RTUs/Data concentrators,

are send over a redundant telecommunications network to the control centers and

then displayed in real time on the workstation consoles of the grid dispatch

operators. This real time data and displays give the operators minute-by-minute

up-to-date information about the status of the network and are also used by the

underlying EMS application modules for real time analysis and computations to

aid them in decision-making.

In addition to some of the supervision, control, data

acquisition, data processing and MMI functions provided by the existing SCADA

system and which would be renewed and extended by the SCADA subsystem of this

new PMS system, this new SCADA subsystem brings in new functionalities such as

[2]

· Topology processor: responsible for analyzing the

open/closed status of network switching devices such as breakers and

disconnectors in order to define the configuration of the network for screen

projection and display.

· Data dissemination: provides the ability to transmit

and receive data (telemetered data, calculated and manually entered data, data

generated by application programs and text data such as alarm messages, event

messages e.t.c to and from other control centers and other computer systems e.g

enterprise management systems or enterprise wide databases, settlement systems

e.t.c.

· Outage scheduler: assist authorized user in scheduling

future outages of power system equipment.

· Information storage and retrieval functions such as

journalizing, energy data collection and calculation, disturbance data for post

mortem review.

The figure below illustrates the different functional

blocks/subsystems of the new PMS and how they interact with each other. The EMS

subsystem has the main task of economically optimizing the utilization of

generation facilities within the constraints imposed by the transmission

network and power/energy exchange contracts or power producers and includes all

the task related to energy purchase, determination of generation cost,

generation maintenance schedules, unit commitment, load frequency control e.t.c

The Energy Management Software in the Power Applications refers to the group of

functions that monitors and controls the generated and exchanged power in the

electric system. In real-time the EMS there would be a significant amount of

coordination between the control center and the various power plant facilities.

System-wide economic benefits are to be achieved when this coordination would

be optimized taking into consideration unit efficiencies, fuel costs and

availability, transmission efficiencies, unit and transmission outages as well

as interchange power availability and price.

Figure 11: PMS

subsystems functions [2]

The following new functionalities amongst others would be

brought in by the new EMS subsystem in capacity and operations planning and

metering and scheduling [1];

· Load forecast: forecast on demand on daily, weekly,

monthly seasonally (rainy and dry season) and annually basis as well as use the

forecasting model predict initially stream flow between the reservoirs

(Mbakaou, Mape and Bamendjin) and the power plants (Edea and Songloulou).

· Economic dispatch: allocate generation in an optimal

manner among committed units to minimize production cost while respecting

reserve requirements and other constraints

· Load Frequency Control (LFC): to keep controlled area's

frequency, area interchange and system time within pre-defined limits.

· Interchange scheduler: allow the operator to develop

record and maintain the interchange transactions negotiated with other systems

and/or generating companies.

· Reserve monitor: to monitor and account for available

generation capacity and system reserves both system-wise and on a generating

unit basis as well as reactive power reserve to allow voltage control

regulation.

· Hydro scheduling: responsible for determining optimal

operation of the hydro system, taking into account constraints and limits.

· Hydro-thermal coordination

· Energy accounting: for calculating the cost of energy

interchanges based on tariffs defined in the respective transactions.

· Power flow: enable operator to study power flow under a

wide variety of different network situations

· Short circuit analysis: analyze potential short

circuits in network and compute fault currents at selected buses and fault

current contributions from other equipment near the faulted buses

· State estimator: application that processes raw

real-time telemetry data and pseudo measurements to provide real time power

flow solution for the entire network as well as detect and isolate failed or

bad data using either the orthogonal transformation algorithm or the normal

equation with constraint algorithm. Also checks and verifies credibility of

data including limits, consistencies and validity.

· Contingency analysis: application that analyses the

threats to the power network that can potentially result from a credible set of

contingent events under steady-state power system conditions e.g. short

circuit, line loss e.t.c using either the Newton-Raphson's or the fast

decoupled power flow algorithm.

· Optimal power flow: application that enables

optimization in the utilization of the power system generation and transmission

network by using a non-linear programming method to identify operating bottle

necks and the marginal cost of binding constraints in MW dispatch, MVAR

dispatch, fuel cost minimization and remedial scheduling.

· Dynamic stability simulation: solve power systems

dynamic problems such providing accurate simulation models and algorithms to

cover the complete range of transient and time frames, calculation of initial

conditions based on power flow results e.t.c

· Harmonic analysis: for carrying out frequency scan and

harmonic load flow for the determination of network natural frequencies and for

filter design.

· Dispatcher Training Simulator: A DTS (Dispatcher

Training Simulator) for both new and experienced dispatchers with main

functions to train new dispatchers, train dispatchers on advanced EMS

applications, train dispatchers on new EMS applications, testing new EMS

packages and post disturbance analysis.

Apart from the SCADA functions of data acquisition, monitoring

and control of hydro stations, the water management system offers the following

addition functionalities [1]

· Forecasting: water flow and water level forecast at the

different hydro stations on the Sanaga and benue rivers, stream flow between

the reservoirs (Mbakaou, Mape and Bamendjin) and the power plants (Edea and

Songloulou) and inflow into the reservoirs during the discharge and filling

periods using a forecasting model that uses measured historical data from hydro

stations and forecasted precipitated data

· Determine the optimal release of water from the

reservoirs to cover entire dry season taking into consideration the hydro plant

cascading on the river basin using a catchment model

· Scheduling of hydro and thermal plants to optmise

resources especially during critical periods such as the dry season

All energy flows into and out of the HV network and other

energy flows within the energy market would be processed by the MMS [1].

Metering data from all the metering points equipped with metering equipments

(modems/IEDs) would be send over a telecommunications network to the central

MMS. This MMS combined AMR system offers the following functionalities

· Data acquisition

· Data storage and processing

· Data validation

· Data reporting and analysis

There is in general a gap between the physical energy flow, which

can be determined by the meters installed in the electrical grid and the energy

flow determined by the rules of the electricity market. The transformation from

meter data into energy data is a crucial function and a prerequisite for the

settlement of the market interactions between the entitled market participants.

The energy data management (EDM) is a software component that transforms

metering data into energy data by processing besides the metering data also the

schedules of the forecasted data for consumption and electricity provision [1].

The EDM system offers the following functionalities using some mathematical,

programmable macro and scheduling functions with an interface to contractual

and economic information [1]

· Transformation from metering data to energy data

· Depiction of commercial transactions

· Energy allocation

· Energy balancing

o identification of deviations between forecasted consumption

schedule and real consumption

o identification between forecasted supply schedule and real

supply schedule

o allocation of balance energy

· Verification of energy supply from various sources

The figure below depicts the flow of metering data from the

metering system through the energy data management system to the billing

system

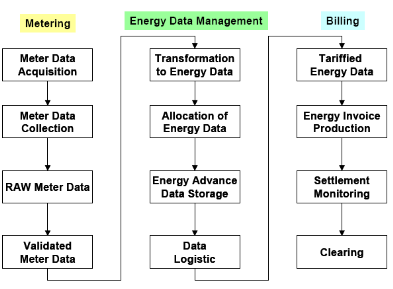

Figure 12: Metering

Management system [1]

The figure above shows clearly the function of an EDM-system

in the context of metering and billing.

1.3.5: The Business

Integration problem

Business integration involves all the processes necessary in

bringing into full and sustained operation equipments (hard and soft) in order

to make sure that they satisfy the needs they were undertaken for during

buying. While the excellent business integration of a system can have

substantial impact on the success of a business, technology alone has no value.

In the case of information systems, business integration includes all the

processes from implementation through transfer and operation to ownership and

the excellent business integration of an information system is indispensable

for

Ø Correct implementation

Ø Complete technology transfer

Ø Full, proper and sustained operation

Ø Absolute ownership

The notion of business integration of an information system

brings in the following important concepts

1. Technology transfer/technology transfer project

management

2. Project implementation/information systems project

implementation

3. Process reengineering

4. Change management

The most successful business integration implementations are

those that meet the business integration requirements and contribute to the

overall success of the business. The successful business integration of an

information system by a business is measured with metrics reflecting the key

performance indicators of the business and not IT metrics.

The socio-technical infrastructure of AESS in the case of

information systems, is made up of obsolete technologies/equipments (hard and

soft), ideas, concepts and technical as well as scientific know-how. A good

example is the LS 2000 SCADA system installed since 1990 by `Landis and Gys'

being used up to today as the main system in supervision and control while

manufacturing of its equipments/components was discontinued since 1999 making

maintenance, upgrade and extension of the system extremely difficult. New

information system technologies/equipments destined for use in operations

management such as for supervision and control, operations planning have faced

serious business integration problems because of this technical, cultural and

conceptual resistance like in the case of the new SKAN4 SCADA system supplied

by Siemens with the aim of renewing and extending the capabilities of the LS

2000 SCADA system as a result of network expansion and increase in the number

of substations, which is not fully operated and has been partially abandoned;

the new daily dispatching software (QSOM) which faced resistance in application

by the dispatch operators e.t.c. This obsolete socio-technical infrastructure

and the concept of routine makes it extremely difficult for AESS to adapt and

change against the reception of new equipments/technology which would impact

the technological, functional and organization aspects of the company.

1.4: Scope of work and

specific objectives

Due to the duration of the internship, this work would consist

more concisely of identifying and studying all the aspects and requirements to

produce specifications and a board of quality assurance measures for (i) total

technology integration to ensure proper and correct implementation of system

equipments; (ii) absolute functional integration to guarantee complete, full

and sustained use of system functionalities and (iii) continual appropriate

organizational integration to ensure total achievement of all technological and

functional benefits, of the SCADA/EMS module (one module of the PMS) for the

southern grid.

CHAPTER 2

GENERAL CONCEPTS AND METHODOLOGY

2.1:

INTRODUCTION

In this chapter, we would be presenting a number of concepts

and techniques which forms the combined methodology used to carry out this

requirement study.

2.2: Systems development

life cycle

The purpose of this a

methodology is to specify a set of well-defined steps or phases, coupled with a

set of clear, measurable exit criteria, for developing and implementing an

information system) [24]. The system development life cycle (SDLC) is a set of

steps that serves as the basis for most systems analysis and design

methodologies.

2.2.1: strengths, weaknesses and limitations

An information system is a set of hardware, software, data,

human, and procedural components intended to provide the right data and

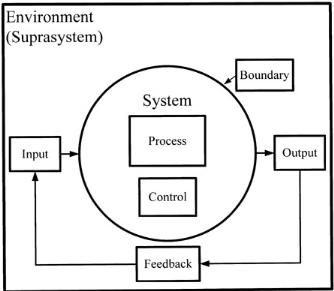

information to the right person at the right time [24]. A system is a set of

interrelated components that function together in a meaningful way, delimited

from its environment (its suprasystem) by a boundary, accepts inputs at its

boundaries and outputs flow back across the boundaries while process is an

activity that changes the system in some way. Of particular interest are the

interfaces, the points at which the various system components communicate or

interact. As a general rule, the more interfaces a system contains, the more

complex the system. The figure below depicts the diagram of a system [24]

Figure 13: A system

[24]

The system development life cycle methodology acts as a memory

aid by imposing discipline, thus reducing the risk that key details will be

overlooked [24]. Communication is enhanced because the methodology imposes a

consistent set of documentation standards. The steps in the methodology enhance

management control, providing a framework for scheduling, budgeting, and

project management [24]. The tools associated with this methodology that makes

it excellent is that it makes it easier to solve the problem of developing and

implementing an information system and also, increases the likelihood that

significant errors are detected early [24].

Using this method, raises a concern that the system developed

may not accurately reflect the current business environment because the elapsed

time between the initial proposal and system completion can be quite lengthy

(often one or more years). Many methodologies require that specifications be

«frozen» as work progresses from one step to the next, and user

requirements do change over time. Given the fast pace of technology, this

problem is particularly acute with hardware and/or software selected early in

the process [24].

This is a traditional methodology used for developing and

implementing many types of information systems, such as expert systems and

real-time processing systems. Additionally, fourth-generation,

fifth-generation, and objected-oriented languages require modifications to the

traditional approach [24].

The project management life cycle is similar to the system

development life cycle, with stages or phases defining a schedule and

triggering resource allocations. Note, however, that a given project might

encompass several related systems, and a given system might be divided into

several sequential or concurrent projects.

2.2.2: The system development life cycle

methodology (the waterfall method)

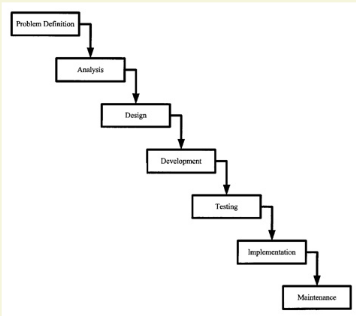

The systems development life cycle is sometimes called the

waterfall method because the model visually suggests work cascading from step

to step like a series of waterfalls with sometimes a considerable feedback

between the various steps or phases [24]. A set of steps for solving

information system problems: the basis for most systems analysis and design

methodologies.

The first step is problem definition. The intent is to

identify the problem, determine its cause, and outline a strategy for solving

it [24].

Given a clear problem definition, analysis begins. The

objective of analysis is to determine exactly what must be done to

solve the problem. Typically, the system's logical elements (its

boundaries, processes, and data) are defined during analysis.

The objective of design is to determine how the

problem will be solved. During design the analyst's focus shifts from the

logical to the physical. Processes are converted to manual procedures

or computer programs. Data elements are grouped to form physical data

structures, screens, reports, files, and databases. The hardware components

that support the programs and the data are defined.

The system is created during development. (Note:

Because the entire process is called the system development life

cycle, some experts prefer to use other labels, such as system creation, for

this stage.) Programs are coded, debugged, documented, and tested. New hardware

is selected and ordered. Procedures are written and tested. End-user

documentation is prepared. Databases and files are initialized. Users are

trained.

Once the system is developed, it is tested to ensure that it

does what it was designed to do. After the system passes its final test and any

remaining problems are corrected, the system is implemented and released to the

user. After the system is released, maintenance begins. The objective of

maintenance is to keep the system functioning at an acceptable level

The figure below depicts the various steps to be followed when

applying the waterfall method

Figure 14; The system

development life cycle is sometimes called the waterfall method

[24]

2.3: Information systems

project implementation

Implementation is the process of completing the system and

turning it over to the user [24]. In the case of an information system, it

includes all the processes involved in site preparation; documentation

preparation; personnel training; system cutover and system release.

Implementation occurs after the system has been analyzed, designed,

constructed, and tested [24].

1. Site preparation: It involves preparing

the work environment, installing the hardware, and configuring any new

equipment to work with existing computers and peripherals. The work environment

includes sufficient space to hold the computer, its peripherals, desks, storage

cabinets, printer stands, and other furniture, and to store such supplies as

paper, ribbons, disks, backup media, forms, cleaning supplies, documentation,

and procedure manuals. Wiring, communication lines, and other physical

connections must be installed. A raised floor might be needed. Security

features might be required [24]. A dependable power supply is essential. Large

computer systems often require custom-designed power supplies. Although most

small computer systems run on standard household current, the equipment can

easily tax the limits of existing wiring (particularly in older buildings), so

rewiring might be necessary. Surge protectors and an uninterruptable power

source (UPS) are recommended for most systems. Air conditioning is another

factor. Computers are heat sensitive, and heat-related problems are difficult

to trace. The computer itself generates heat, and that can add to the air

conditioning load. The cost of inadequate air conditioning is often measured in

excessive downtime and high maintenance costs. Ergonomic requirements are

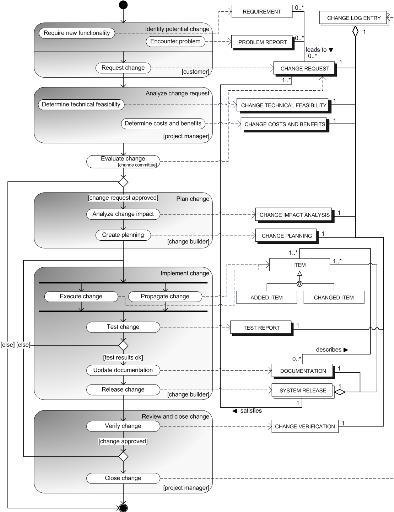

intended to provide the users with a comfortable working environment. Key